This document and the information contained herein, is the exclusive property of MODE. And represents a nonpublic,

confidential and proprietary trade secret that may not be reproduced, disclosed to third parties, or otherwise employed in

any manner. whatsoever without the express written consent of MODE. Copyright © (2016) MODE. Allrights reserved.

APPENDIX: INSPECTING CHAIN WEAR

Measuring Wear on the Chain

Note: The chain should be inspected regularly for wear, rust and corrosion.

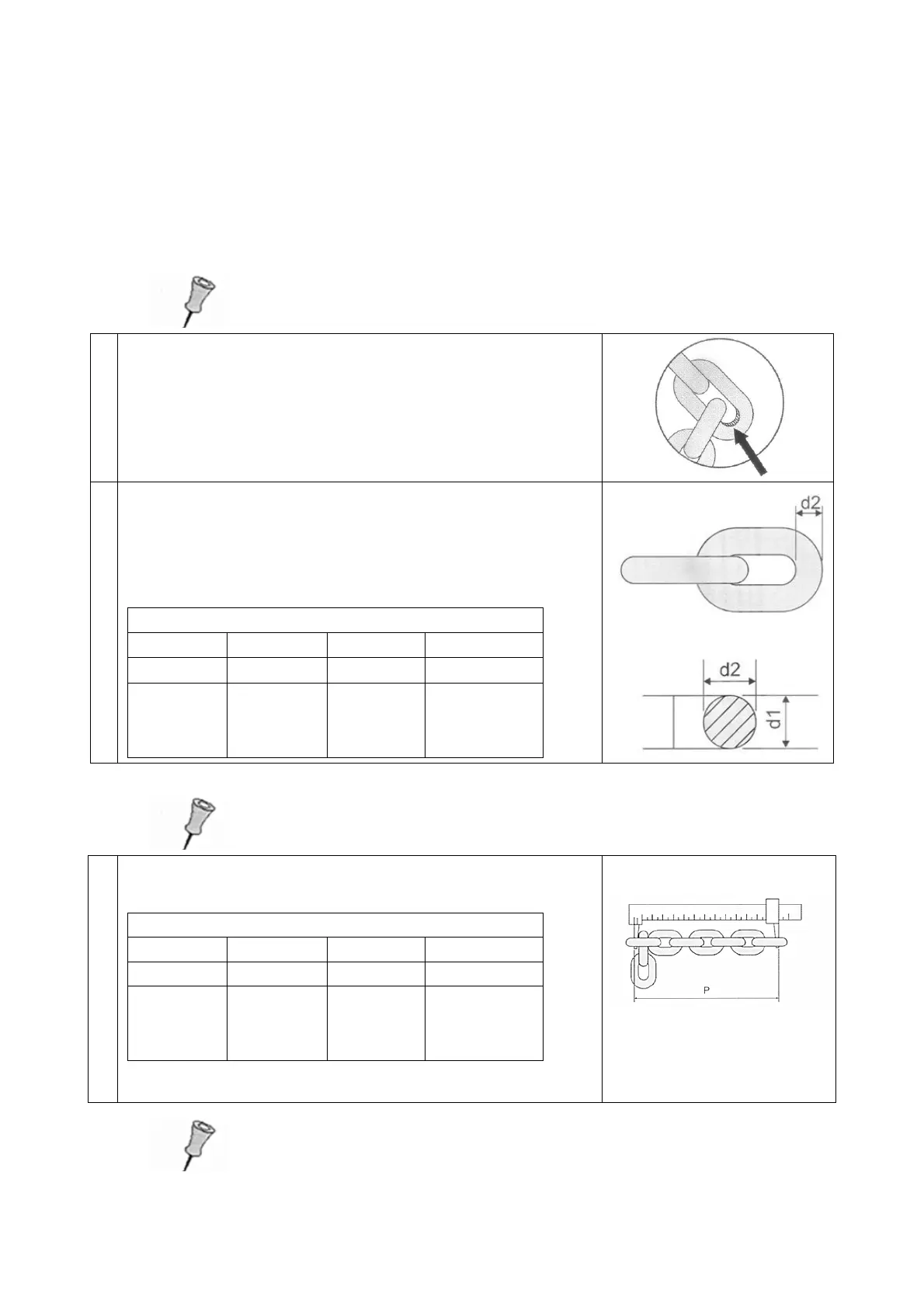

VISUAL CHECKS

Examine visually for gouges, nicks, weld splatter, corrosion or

distorted links and slacken chain. Check bearing surfaces between

links for wear.

A chain with excessively pitted, corroded, nicked, gouged, twisted or

worn links should be replaced with a factory approved chain.

Measure link thickness (d)

Measure the dimension (d) at several points of the chain and

calculate the dimension (dm).

dm = (d1+ d2) 12 < 0.9 * dn

dn = nominal

t = pitch

Criteria:

Note: Use only a "knife-edge" caliper to eliminate the possibility of false

reading by not measuring full pitch length.

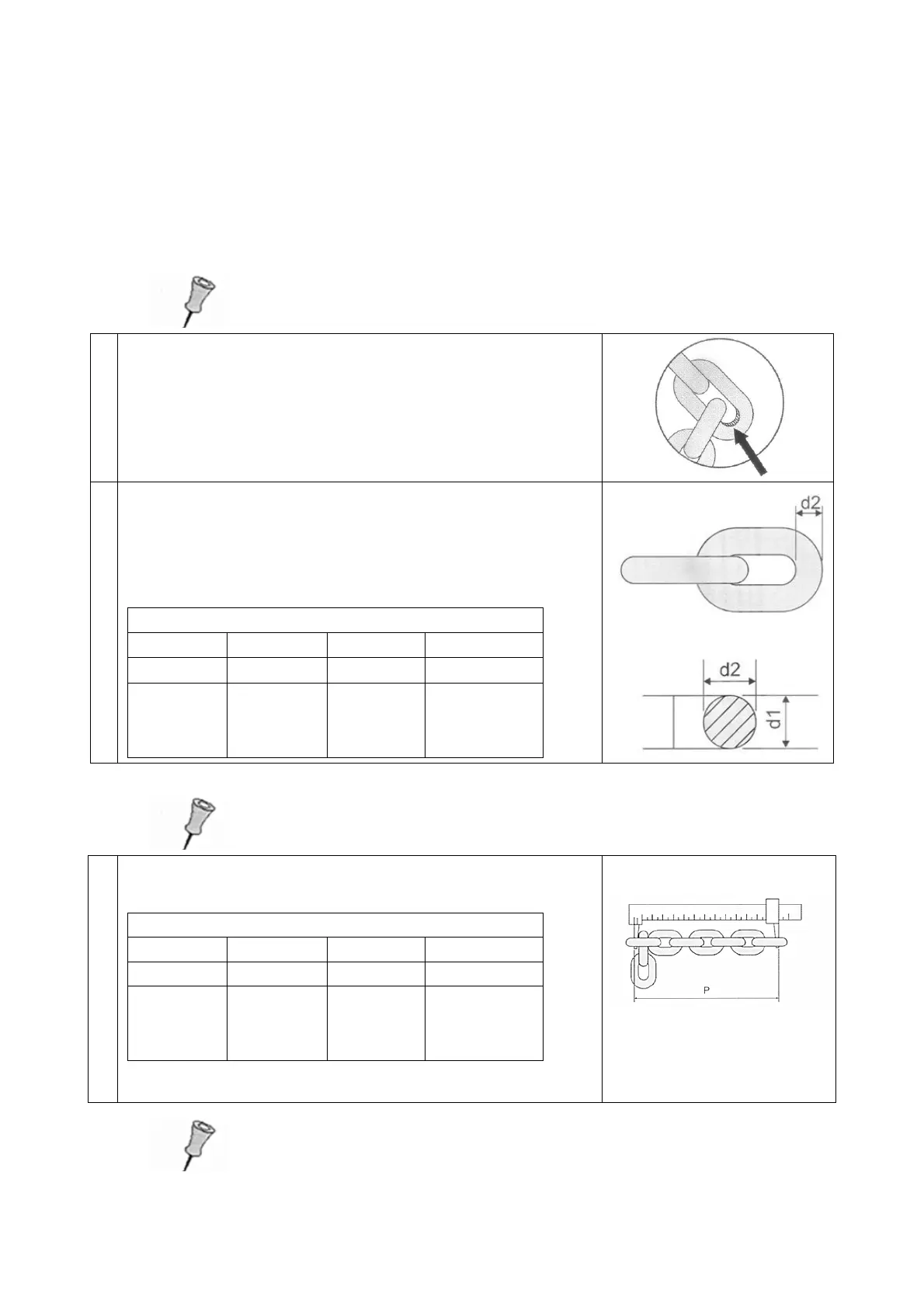

Measure elongation (P)

Measure (P), the pitch over 11 links, at different regions of the chain.

Criteria:

*NOTE: 2% elongation as per ISO 7592.

Note: If these limits are exceeded, the chain must be replaced immediately. In

this case, wear on the guide chain and chain sprocket should also be checked

and they should be replaced if necessary.

Loading...

Loading...