This document and the information contained herein, is the exclusive property of MODE. And represents a nonpublic,

confidential and proprietary trade secret that may not be reproduced, disclosed to third parties, or otherwise employed in

any manner. whatsoever without the express written consent of MODE. Copyright © (2016) MODE. Allrights reserved.

Operators SHALL NOT operate the equipment while suffering from

any illness or injury which might impair their ability to properly use

the equipment.

7.2 Checks to Be Done Before Every Working Shift

Before every working shift, the operator SHALL make the following checks to ensure that the

product is in a safe operating condition. By carrying out these simple checks, the operator can

identify potential problems at any early stage, thereby enhancing safety and minimizing down

time.

If any abnormal condition or malfunction is noted on the daily

inspection or occurs during daily operation, report it to the supervisor

immediately and remove the product from use. Operation may only

continue when safe operation is ensured.

Operating a product with an abnormal condition or malfunction can

result in serious injury or death or serious damage to the product.

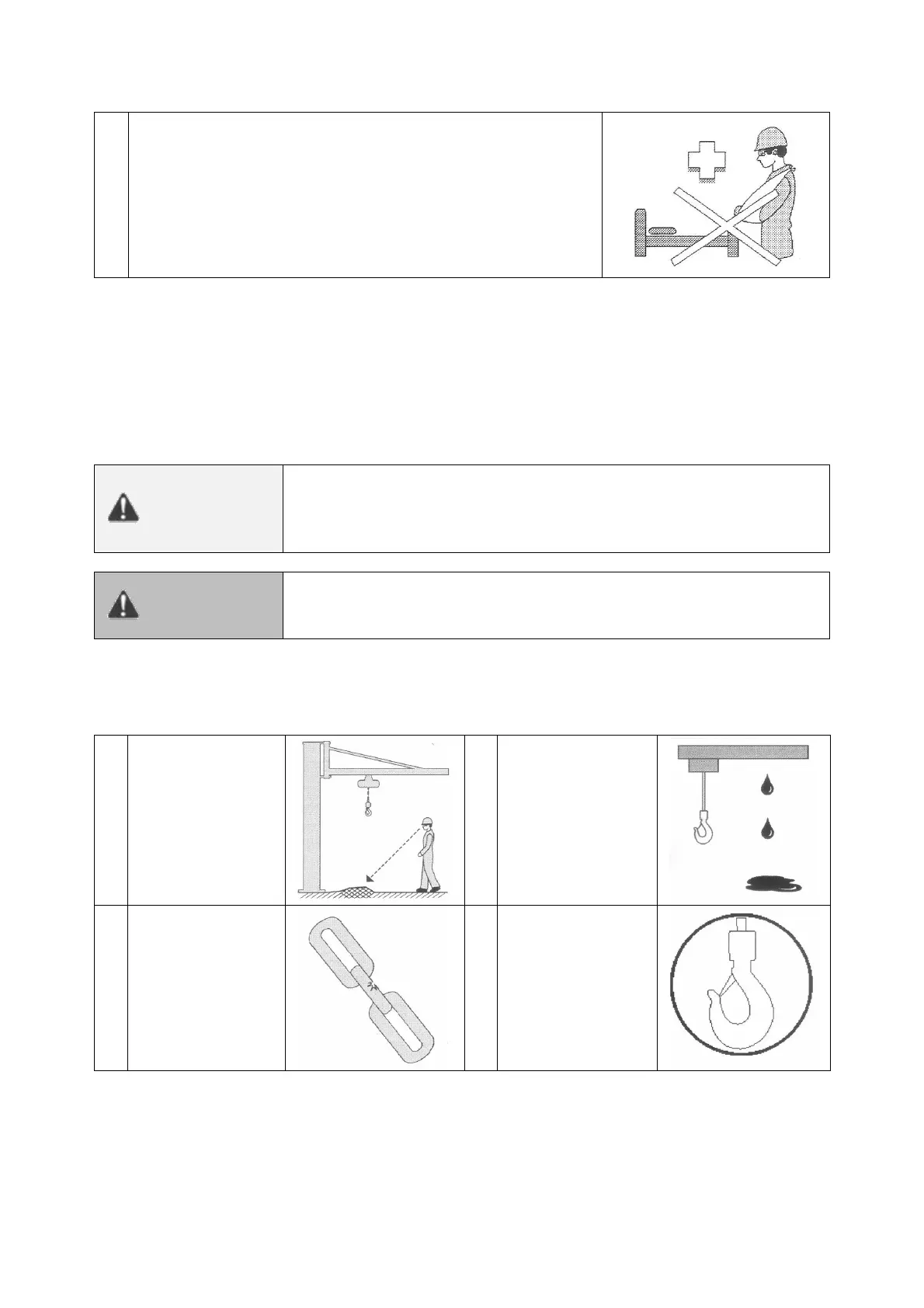

7.2.1 Checks to be performed by the operator

Visually check the

operating

environment to

make sure that there

are no new hazards

which might prevent

safe use

Visually check to see

if there are any oil

leaks from the

product.

Visually check the

chains for any

deformation or

damage or twist (in

2 falls models).

Check the chain for

cleanness and

proper lubrication.

Inspect the hook for

nicks, gouges,

deformation of the

throat opening, wear

on saddle or load

bearing point, and

twisting.

Loading...

Loading...