This document and the information contained herein, is the exclusive property of MODE. And represents a nonpublic,

confidential and proprietary trade secret that may not be reproduced, disclosed to third parties, or otherwise employed in

any manner. whatsoever without the express written consent of MODE. Copyright © (2016) MODE. Allrights reserved.

If applicable, close

mechanical brakes

such as rail clamps,

storm locks etc.

Check the hoist for

any visible damages.

Report all observed

defects and

abnormalities in

equipment or

operation to the

foreman and to the

next operator.

Always remove the product from service immediately if it is in a

dangerous W/U^NING condition. Operating a product that is in

dangerous condition could cause death or serious injury.

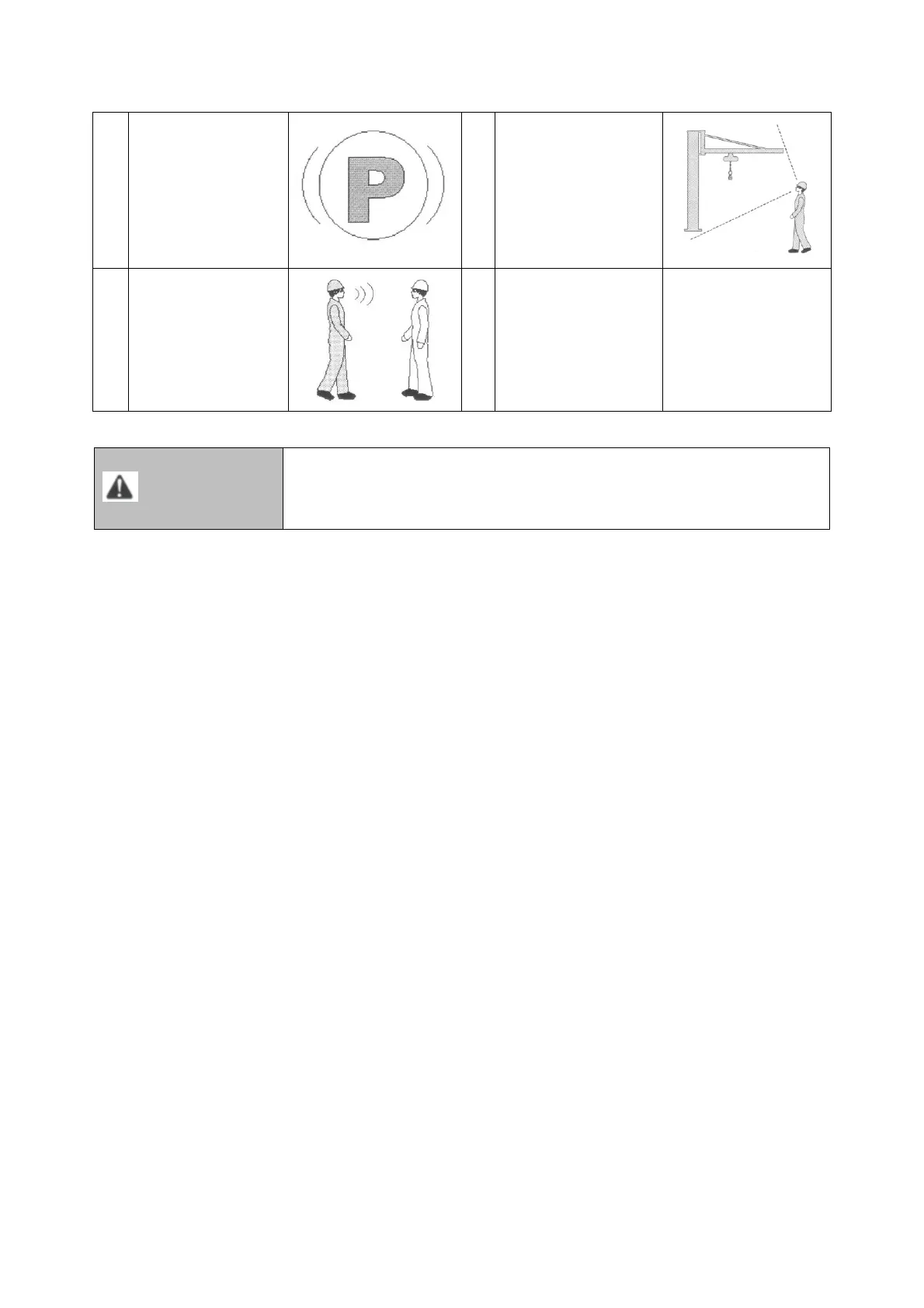

7.7 Hand Signals and Other Methods of Communication

When one person is operating the product and another is giving hoisting instructions,

communication must be clear. Both people must agree on and understand the language they

use to describe hoisting actions.

If electronic voice communication is used, such as telephone or radio, a dedicated channel

must be used so that any commands from other personnel in the area will not confuse the

operator.

ANSI standard hand signals can be used for communication (see Appendix - ANSI standard

hand signals). Other standards for hand signals exist. The operator must be trained in the use

of appropriate hand signals. A copy of the hand signals should be displayed at the operator's

station and anywhere else where it could be useful.

Special operations may require additional hand signals. Special signals must be agreed upon

and understood before hoisting. It should not be possible to confuse special signs with the

standard signs.

The operator should only respond to hand signals from the person giving hoisting instructions,

except to obey a stop signal, regardless of who gives it. The operator takes overall

responsibility for movement and should only follow movement instructions when he or she

judges it safe to do so.

Loading...

Loading...