This document and the information contained herein, is the exclusive property of MODE. And represents a nonpublic,

confidential and proprietary trade secret that may not be reproduced, disclosed to third parties, or otherwise employed in

any manner. whatsoever without the express written consent of MODE. Copyright © (2016) MODE. Allrights reserved.

Hoisting limit switch

If the hoist is equipped with electrical limit switches, check for

correct operation of the limit switches by raising and lowering the

hook at low speed until the limit switches are activated and prevent

further upward or downward movement.

In case the desired function is not activated at desired position,

adjust the limit switches according to the adjustment instructions

given under 'Operational Checks with Controller Enabled’.

If that does not help, geared limit switch needs to be replaced.

Functional description of the limit switch

2-step geared limit switch

The 2-step geared limit switch together with controls is working as

an adjustable upper and lower stop limit.

4-step geared limit switch

The 4-step geared limit switch provides an adjustable upper and

lower stop limit connected to the internal controls. Two (2) cams are

not connected to the controls, and can thus be freely used for

end-user requirements.

Traveling limit switches shall always be adjusted before the

commissioning tests can be continued.

Operating sound and movements

Listen to the operating sound when the product is hoisting or

traveling. Pay attention to unusual noises such as squealing.

Check that the hoist is running smoothly. There should not be any

strong vibration.

Any defects or abnormalities which are detected during the

commissioning must be investigated and corrected in accordance with

the instructions relevant to the component in question.

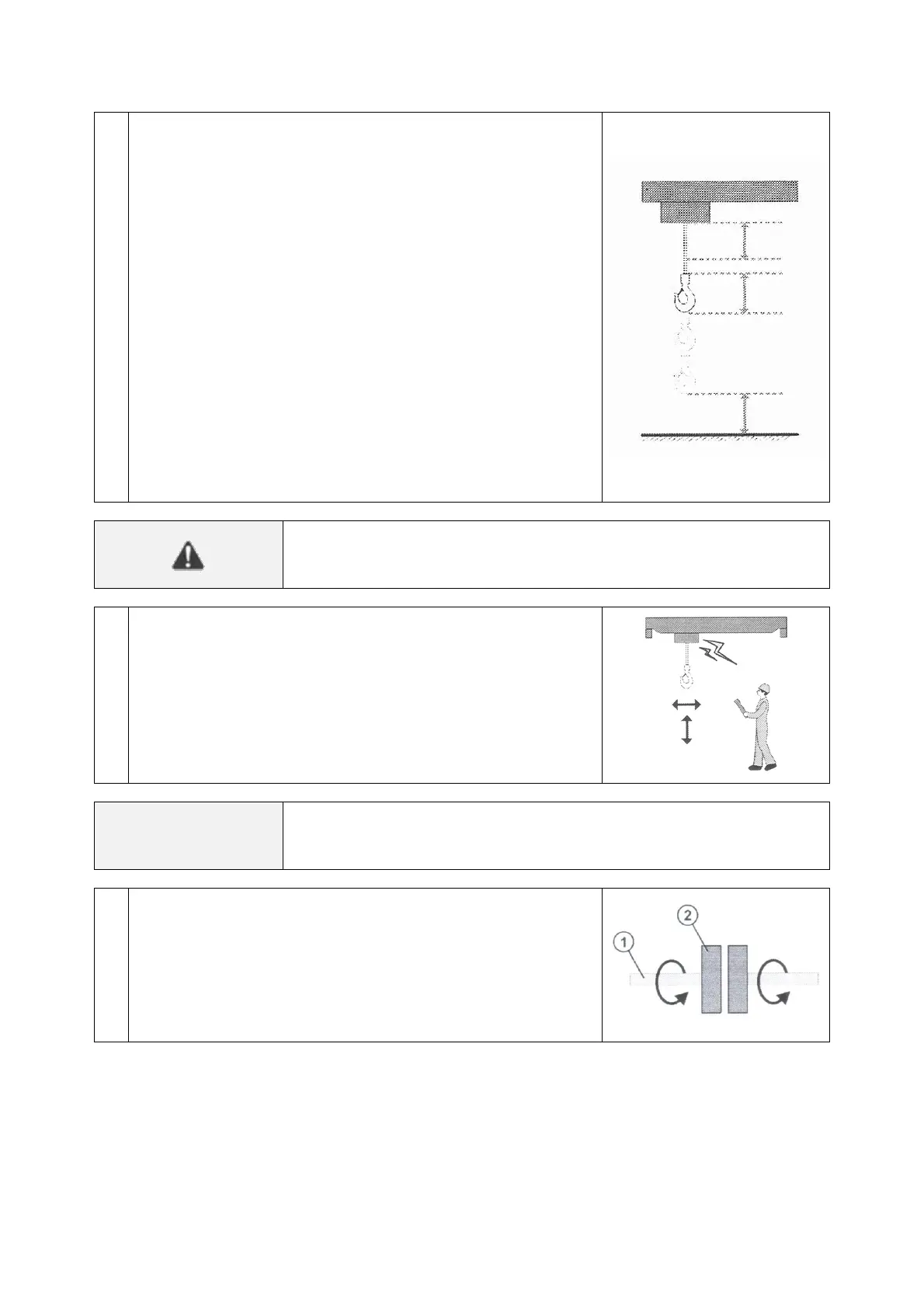

Slipping clutch

Check that the slipping clutch mechanism works correctly.

When the torque caused by load (1) exceeds the designed hoisting

limit, the clutch discs (2) should begin to slip, preventing upward

hoisting movement.

Loading...

Loading...