Before starting this type of unit, ensure that all personnel involved have read and understood the " Safety" chapter in

this manual.

1. The unit shut-off valves must be open.

2. With a “closed” type hydraulic circuit ensure that a suitably sized expansion vessel has been installed.

3. Check that the ambient temperature is within the range indicated on the unit's data plate.

4. Check that the main switch is in the OFF position (“O”).

5. Check that the unit power supply voltage is correct.

6. Power the unit by means of the line protection device.

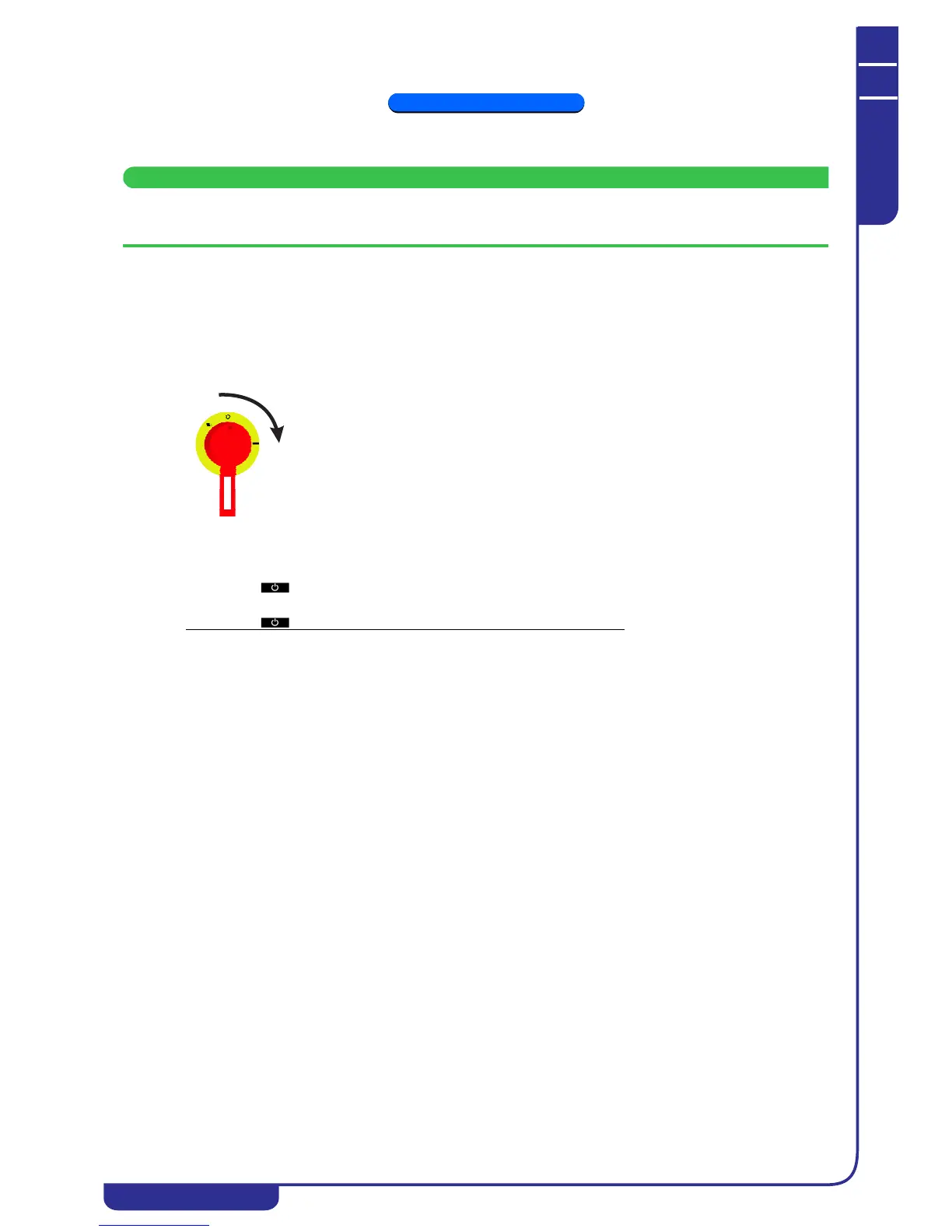

7.Turn the unit main switch to the ON position (“I”).

When the unit is powered the control unit display switches on. Check on the display for:

• unit alarm

• Time bands Off

• Supervision Off

• “External On/Off” Off

8.Models without pump:

before switching the unit on make sure the water pump is running and water is flowing

through the evaporator.

9. Models with discharge valves on compressors:

Check that the compressor discharge valves are open.

10. Press button for 2" to start the unit. The pump (if installed) starts immediately.

After a delay set on the electronic board the refrigerant compressor starts.

Press button again for 2" to stop the unit. The controller remains active

.

11. Compressors, pump and fans have only one correct direction of rotation.

If a SCROLL compressor does not rotate in the correct direction it will be very noisy and will be unable to

compress the refrigerant gas.

Check the direction of rotation of all components at first start and after every maintenance operation. In the event

of incorrect rotation direction of all components, invert two phase wires at the main terminals of the electrical

cabinet. In contrast, if it is found that only certain specific components are rotating in the incorrect direction, the

power feeding wires must be inverted on the individual terminals of the corresponding contactor(s) (see attached

wiring diagram).

12. If, at the time of the first start of the unit in CHILLER (SUMMER) mode the ambient temperature is high and

the temperature of water in the hydraulic circuit is significantly higher than the working value (e.g. 25-30 °C) this

means that the unit is starting in overload conditions so the protections may trip. To reduce the overload, partially

and progressively close a valve at the unit outlet to reduce the flow rate of water passing through the

evaporator. The valve can be opened fully when the water temperature in the hydraulic circuit approaches the

working value.

Similar considerations are valid with low ambient temperature and user circuit water temperature

significantly lower than the working value at the first start in HEAT-PUMP mode (“WINTER”).

Loading...

Loading...