MAINTENANCE AND OPERATING MANUAL

Troubleshooting

HAS T 070÷140

95

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

CHAPTER 9

TROUBLESHOOTING

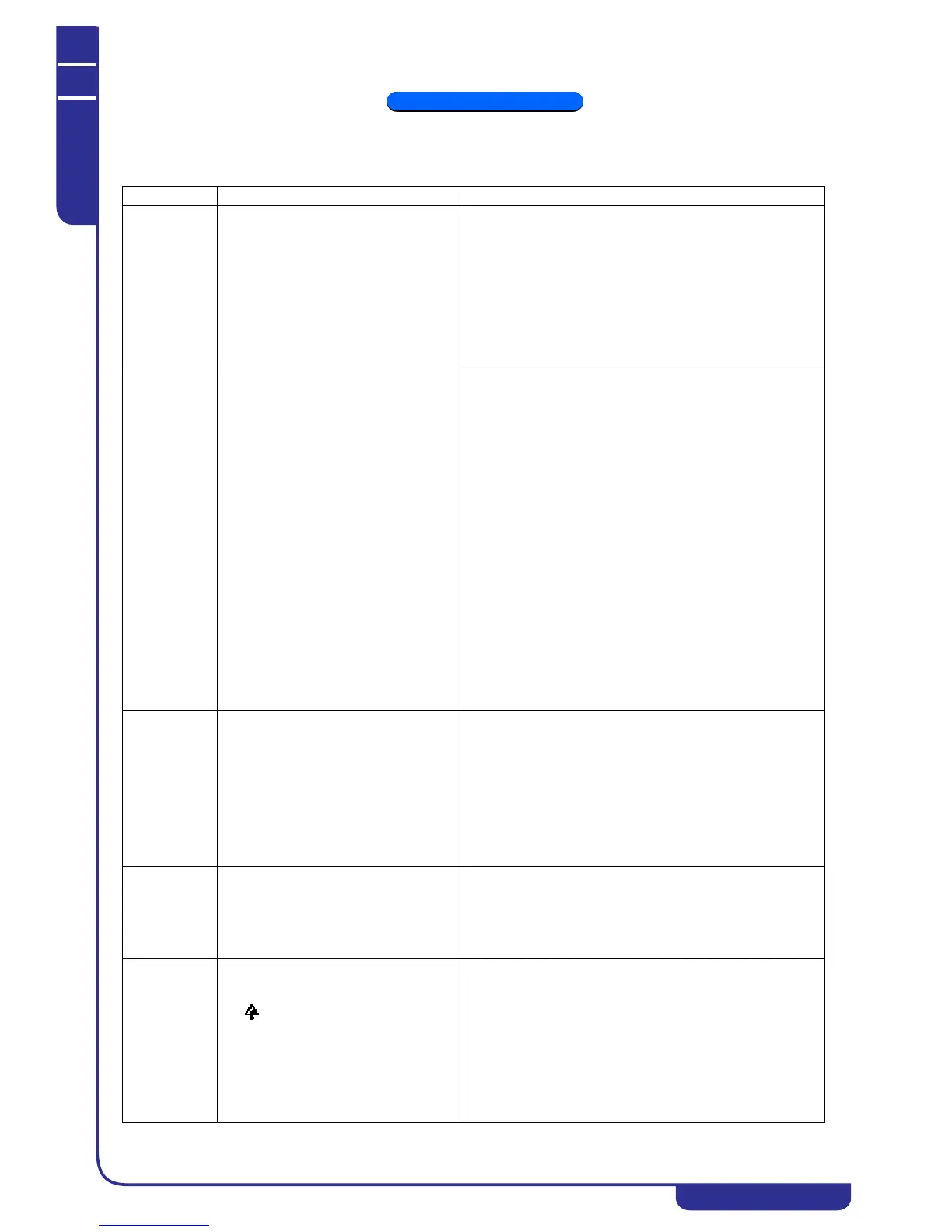

PROBLEM SYMPTOM CAUSE/REMEDY

A

Unit fails to

start

• Unit is powered and yet fails to start. Presence of shut-down alarms

Check for the presence of alarms that prevent the unit from starting.

Unit programmed to run by time band

The unit is set to start only within the programmed time bands.

Activate start mode outside the time bands in the User stage.

Supervision active

Check that supervision is not enabled on the unit.

Enter the supervision stage and disable supervision function.

Remote control active

Disable remote mode to start the unit.

B

Water outlet

temperature

higher than

set-point.

• Unit is operational but water temperature

is higher than the set-point value.

• BTOWT temperature higher than

prescribed value.

• High water outlet temperature alarm trip.

• Low evaporation pressure.

• Presence of a large number of air bubbles

in the liquid sight glass.

• Excessively noisy operation of

compressors.

Water flow rate too high

Increase hydraulic circuit pressure drop (for example: by partially

closing a pump discharge valve).

Thermal load too high

Restore thermal load to within prescribed limits.

Ambient temperature too high

Increase air recirculation.

Condenser fins fouled

Clean the condenser fins.

Front surface of the condenser blocked

Remove the obstruction from the front surface of the condenser.

Incorrect direction of fan rotation

Invert the position of two of the three phase wires of the power

supply.

Circuit has insufficient refrigerant charge

Call in a qualified refrigeration engineer to check for leaks and

eliminate them. Have the circuit charged by a qualified refrigeration

engineer.

Incorrect compressors rotation

Invert the position of two phase wires of the compressors power

supply (see chap. " Start-up").

C

Insufficient

pressure

head (water

pressure) at

the outlet of

the pump

(if present).

• Rise of water outlet temperature.

• With pump installed: pressure difference

(read on the unit pressure gauge) with

pump running and pump stopped is too

low.

• Increase in the pressure drop due to the

presence of ice.

• High temperature difference between

water inlet and outlet.

Water flow rate too high

Restore flow rate to within prescribed limits, for example by

partially closing a pump delivery cock.

Presence of ice in the evaporator

Stop the unit, leave the pump running, edit the set-point value and

add ethylene glycol to the water.

Evaporator blocked

Supply a high flow rate of water in countercurrent conditions.

Install a filter upline from the unit.

D

The unit is

blocked and

water does

not flow.

• No water flow.

• Water differential pressure switch (not

present)/flow switch alarm trip.

• Low pressure alarm trip.

• Suction pressure too low.

Set-point value too low

Increase the SET-POINT value or add ethylene glycol (antifreeze)

in adequate percentage (see heading "4.3.4 Freeze protection").

The formation of ice can severely damage the unit.

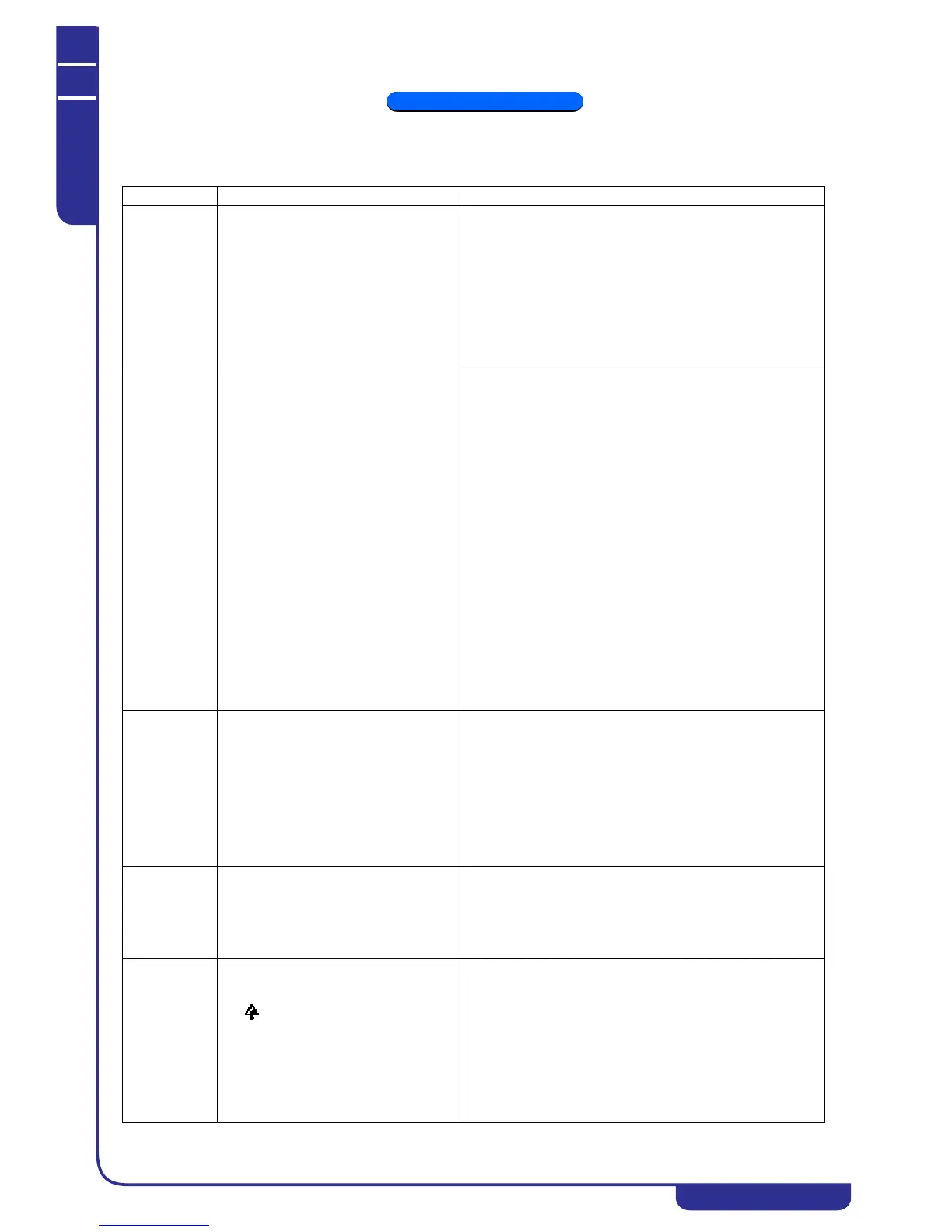

E

High

pressure

• High pressure switch trip.

• Refrigerant compressor stops.

• icon illuminates.

• General alarm relay trip.

• Fans stopped or reverse rotation

direction.

• Water outlet temperature too high.

Fans stopped or incorrect rotation

Repair or renew the fan.

Invert the position of two phase wires of the fan power supply.

Warm air recirculation

Change the position of the unit or the position of any nearby

obstructions in order to prevent recirculation.

Coil fouled

Clean the condenser fins.

Thermal load too high

Restore thermal load to within prescribed limits.

Loading...

Loading...