MAINTENANCE AND OPERATING MANUAL

Electronic controller

HAS T 070÷140

72

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

KD: derivative coefficient. This is the rate of temperature variation. The contribution of this coefficient increases damping

and stability of the system.

Coefficient KI acts on the regulation only when the reference temperature is within the Wind-up band. The KD coefficient

influences regulation at intervals corresponding to the sampling time.

The sum of contributions of the three parameters generates a regulation variable in relation to which the unit's compressors

are stopped and started.

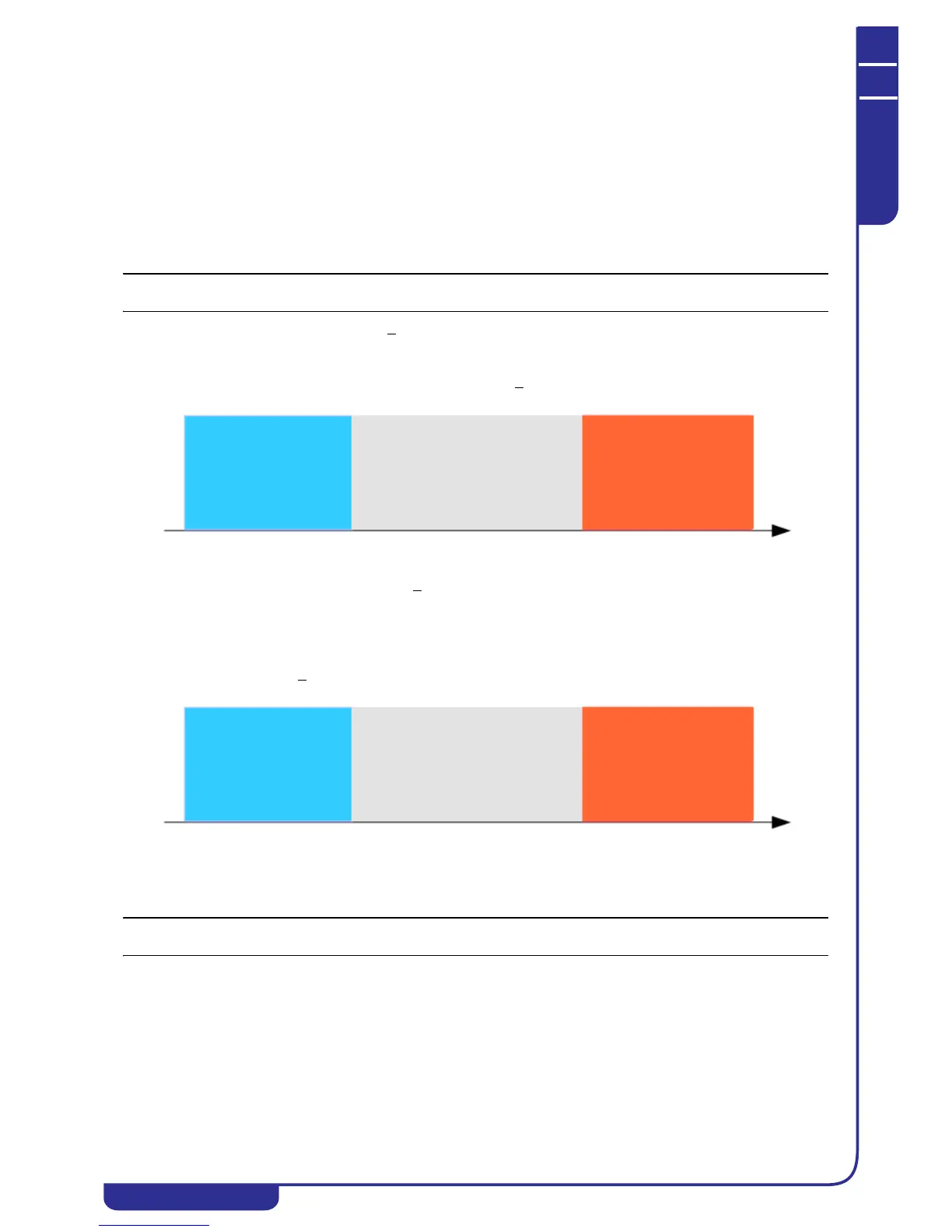

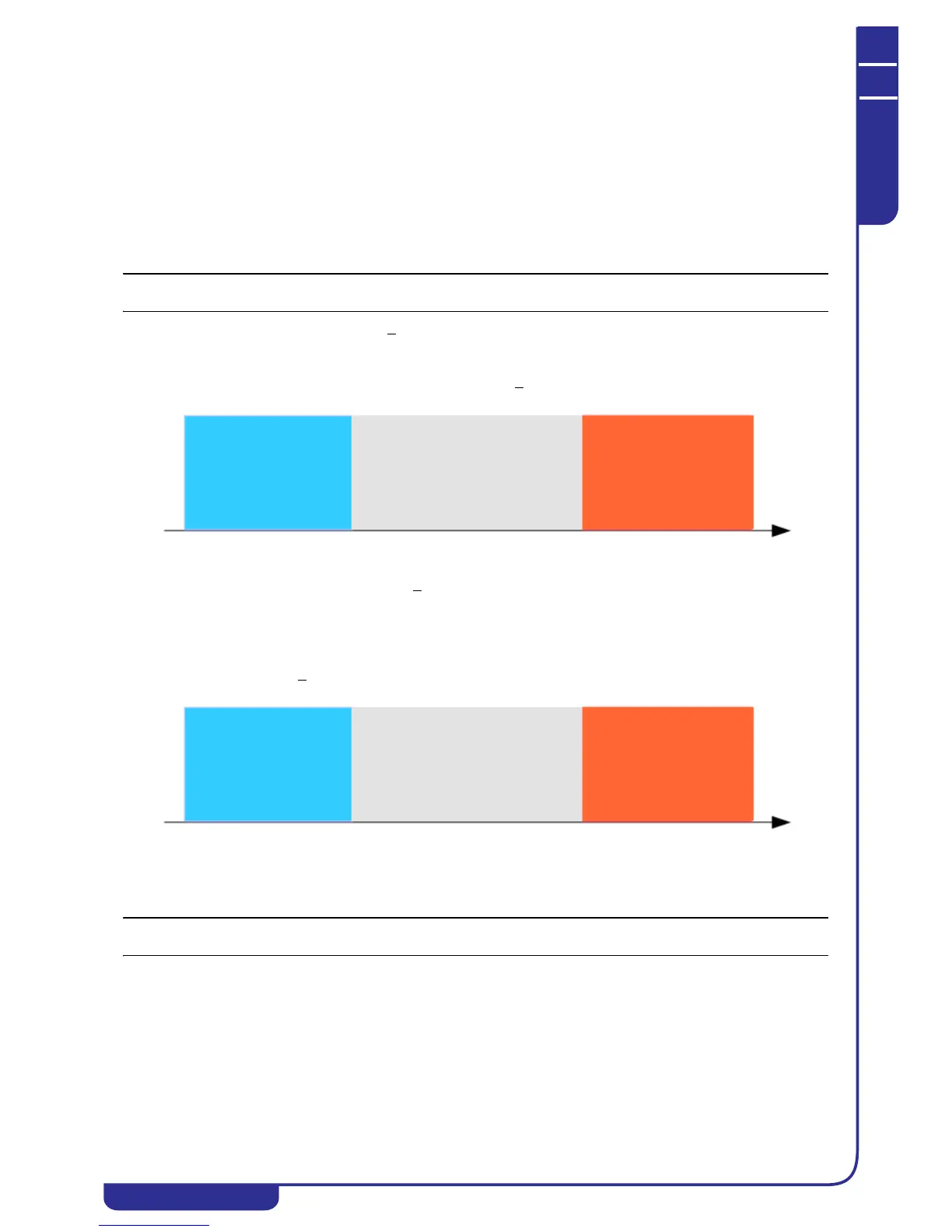

NEUTRAL ZONE REGULATION

In neutral zone regulation the unit's compressors are started and stopped in accordance with the setpoint and the regulation

band or differential observing the reference time intervals.

Neutral zone means the deviation between the setpoint and the regulation bandwidth.

In chiller mode, if the reference temperature is > Setpoint+Diff, the unit's compressors are started in sequence, in compliance

with the starting time lag outside neutral zone. If the reference temperature is within the neutral zone, the unit's compressors

are started in sequence in compliance with the starting time lag in the neutral zone. Starts occur only if at least one of the

unit's compressors is already running. If the reference temperature is

< Setpoint, the unit's compressors are stopped in

sequence, in compliance with the stopping time lag outside neutral zone.

In heat pump mode, if the reference temperature is > Setpoint-Diff, the unit's compressors are started in sequence, in

compliance with the starting time lag outside neutral zone.

If the reference temperature is within the neutral zone, the unit's compressors are started in sequence in compliance with the

starting time lag in the neutral zone. Starts occur only if at least one of the unit's compressors is already running.

If the reference temperature is

< Setpoint, the unit's compressors are stopped in sequence, in compliance with the stopping

time lag outside neutral zone.

6.7.9 Defrost

The menu is accessible by means of the service level password and with defrost enabled.

During operation in heat pump mode, the unit's condensing coils function as evaporators so there is a risk of their surfaces

icing up. The defrost procedure makes it possible to avoid ice formation on the coils by inverting the operating cycle of the

unit for a defined time interval.

In the DEFROST menu you can define the parameters for control of the procedure, notably the defrost type which can be

chosen from:

• Independent: in defrost conditions each circuit activates the procedure irrespective of the status of the other

circuits;

• Separate: in defrost conditions each circuit checks the status of the other circuits and waits for the termination

of any defrost procedures in progress before starting its own defrost cycle;

The unit can manage a maximum number of defrost cycles per hour which, if exceeded, generates a warning on the

display.

Reduction

Cooling capacity

Neutral

Increase

Cooling capacity

Set

Set+Diff

Temperature

Zone

Reduction

Cooling capacity

Neutral

Increase

Cooling capacity

Set-Diff

Set Temperature

Zone

Loading...

Loading...