MAINTENANCE AND OPERATING MANUAL

Operation and maintenance

HAS T 070÷140

94

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

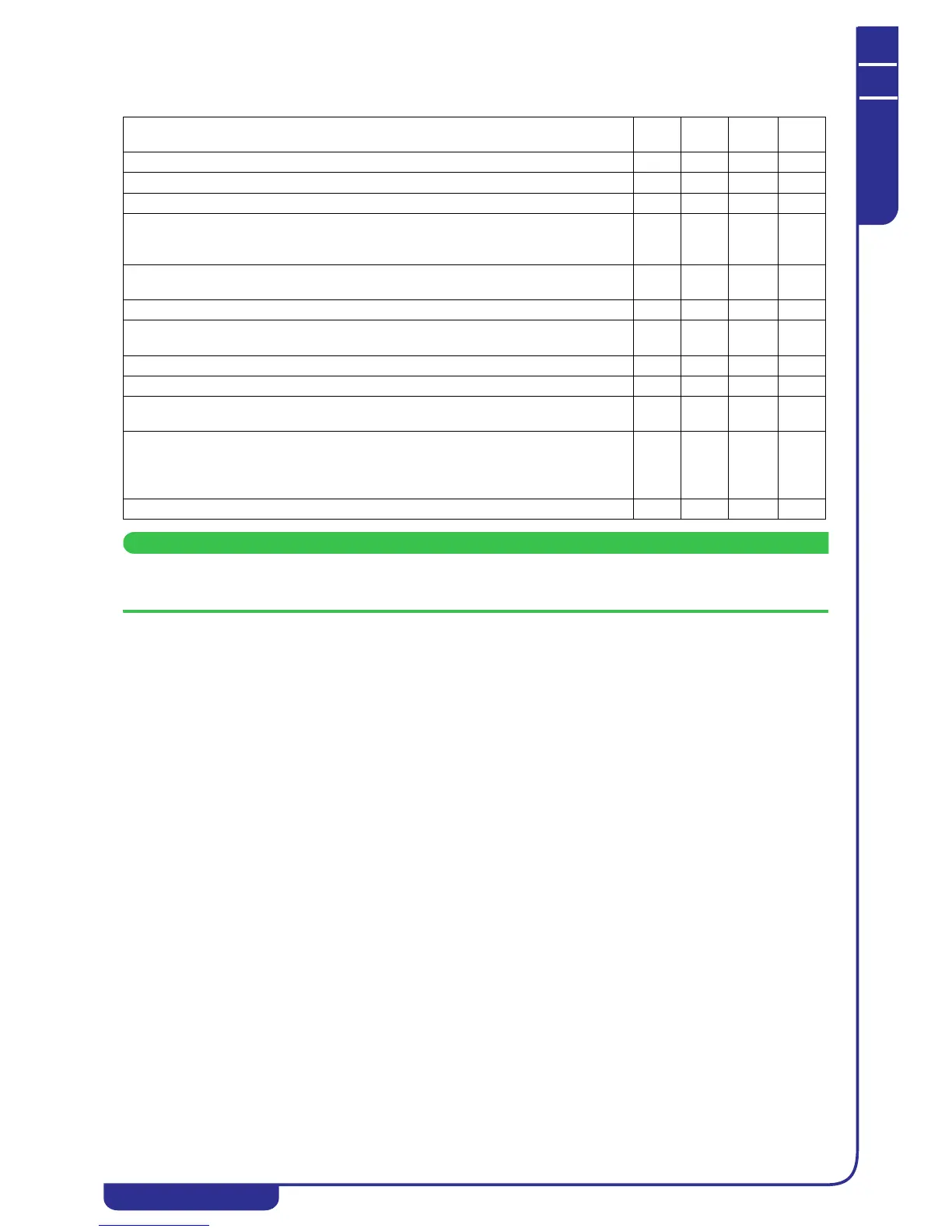

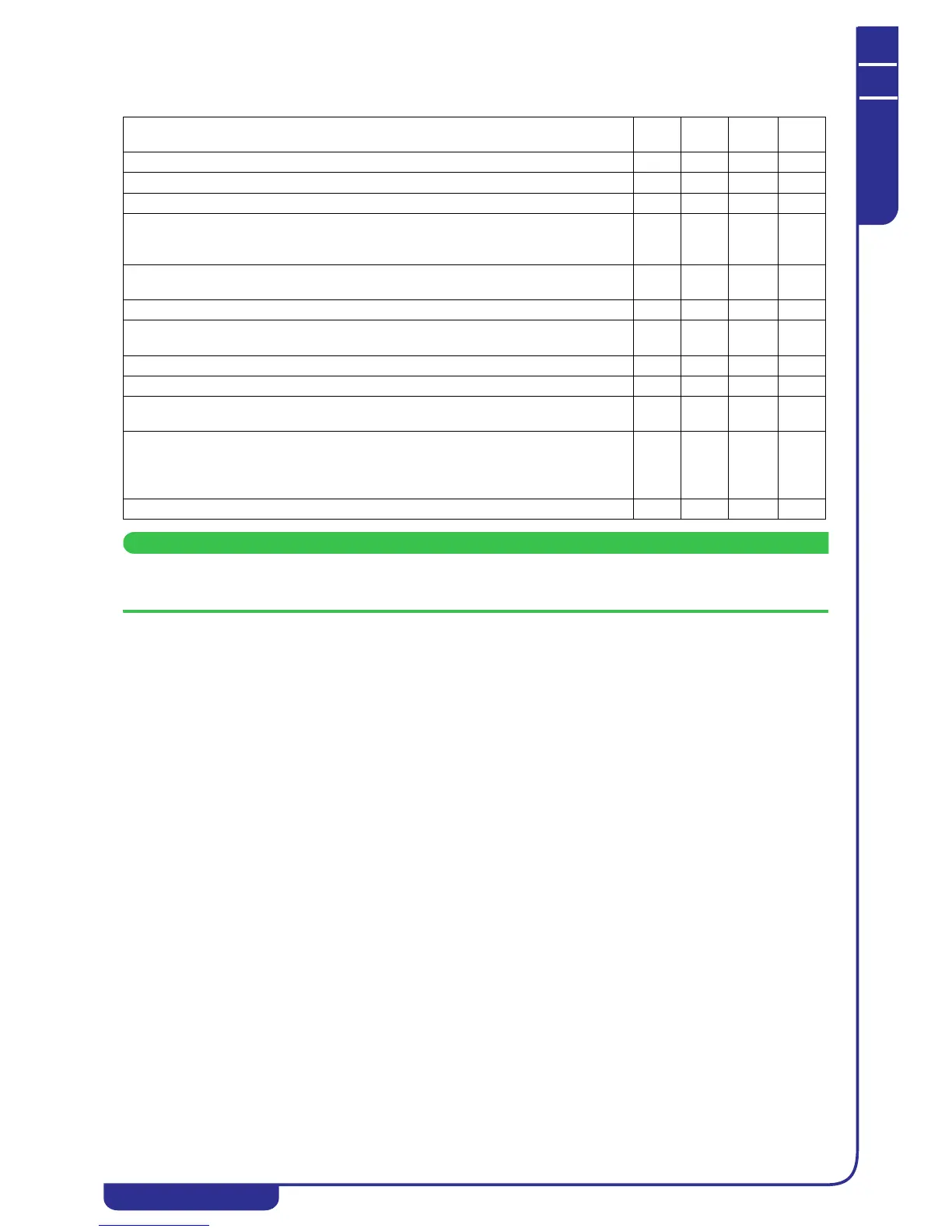

8.2.3 Planning of checks and maintenance operations

The above maintenance schedule is based on average operating conditions.

In some cases it may be necessary to increase maintenance frequency.

OPERATION

1

Day

1

Month

6

Months

1

Year

Check to ensure there are no alarm signals.

Check that water outlet temperature is within the programmed interval.

Check that user water inlet temperature is commensurate with the unit capacity.

Check that the difference between the pump (if present) discharge pressure and suction

pressure (measured on the pressure gauge with pump stopped) is within the prescribed

range and not lower than the pump maximum flow rate value.

Check that the liquid sight glass is always full or shows a minimum passage of bubbles

when the compressor is running.

Check that the unit's current absorption is within the data plate values.

Make a visual inspection of the refrigerant circuit to make sure the piping has not

deteriorated and there are no traces of oil, which may indicate a leak of refrigerant.

Check the condition and soundness of piping connections.

Check the condition and soundness of the electrical connections.

Check that ambient air temperature is commensurate with the unit's capacity.

Check that the area in which the unit is installed is well-ventilated.

Check that fans are automatically controlled by the electronic control unit.

Check for any unusual noises.

Clean the condenser fins with a soft sponge or a jet of clean compressed air.

Make sure the grilles are free from dirt and any other obstructions.

Clean the condenser fins with mild detergent.

Loading...

Loading...