MAINTENANCE AND OPERATING MANUAL

General information

HAS T 070÷140

6

ENGLISH

EN

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited.

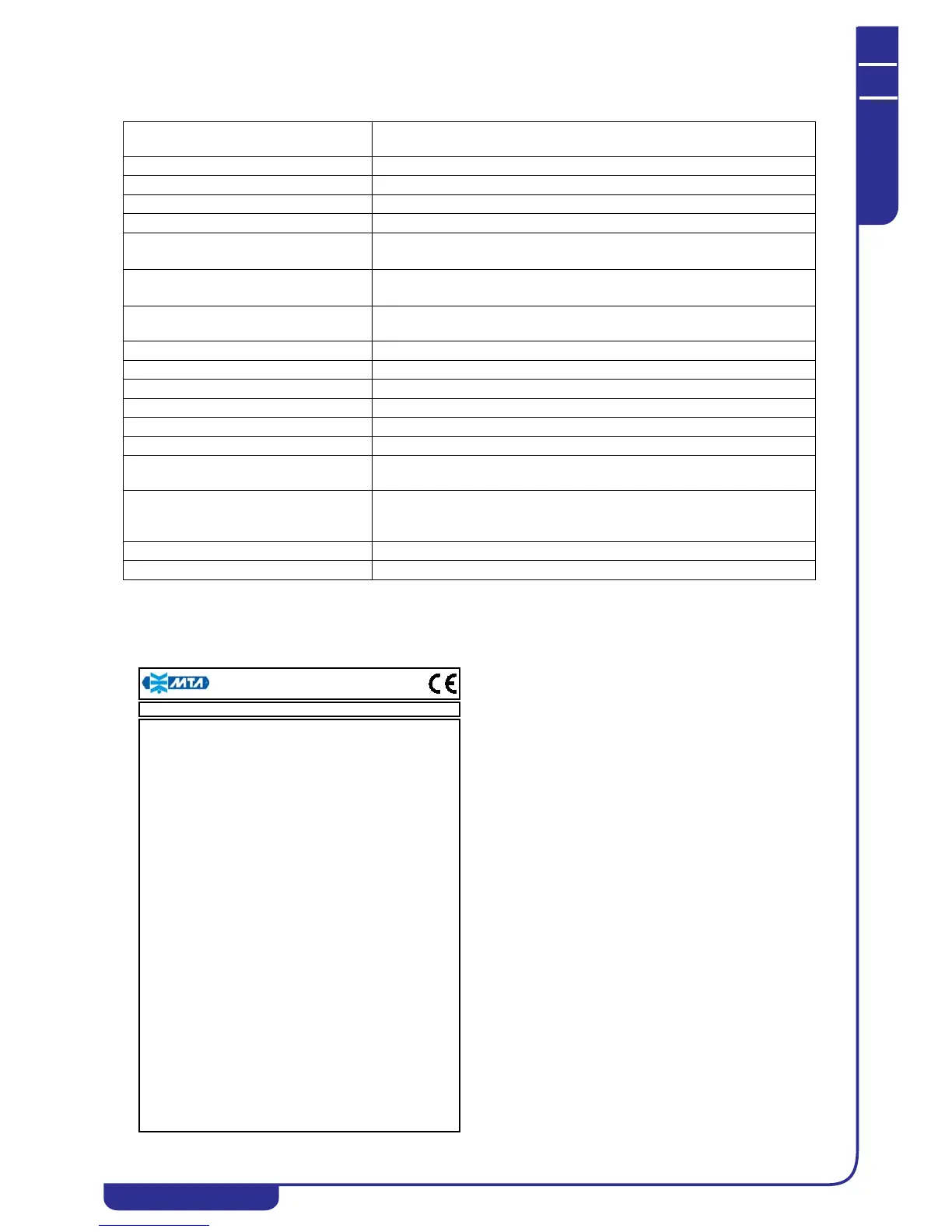

1.3 Data plate

The data plate affixed to the unit shows the main technical data.

1.4 Declaration of conformity

MODEL and CODE Identify the size of the unit (see Chapter 1 “General information“) and the

type of construction.

MANUAL Code number of this manual.

SERIAL NUMBER Unit serial number or manufacturing number.

YEAR OF CONSTRUCTION Year of unit's final testing.

VOLTAGE/PHASES/FREQUENCY Power supply specifications.

MAX CURRENT INPUT

I

MAX

Unit current input in limit working conditions

INSTALLED POWER

P

MAX

Unit power input in limit working conditions

PROTECTION RATING Protection rating of the entire unit, according to European standard EN

60529.

REFRIGERANT Type of refrigerant charge with which the unit is filled.

REFRIGERANT CHARGE Quantity of refrigerant supplied to the circuit.

MAX. REFRIGERANT PRESS. HP SIDE Refrigerant circuit design pressure (high pressure side).

MAX. REFRIGERANT PRESS. LP SIDE Refrigerant circuit design pressure (low pressure side).

USER CIRC. FLUID Fluid cooled or heated by the unit (usually: water).

MAX. WORKING PRESSURE User circuit maximum design pressure.

MAX TEMPERATURE User circuit maximum design temperature - not to be confused with the

maximum working temperature, which is specified at the time of the offer.

SOUND PRESSURE LEVEL Free field sound pressure level in hemispherical radiation conditions

(open field) at a distance of 1 m from the condenser side of the unit and a

height of 1.6 m from the ground.

AMBIENT TEMPERATURE Thermal exchange air minimum and maximum temperature values.

WEIGHT Approximate weight of the unit without packaging.

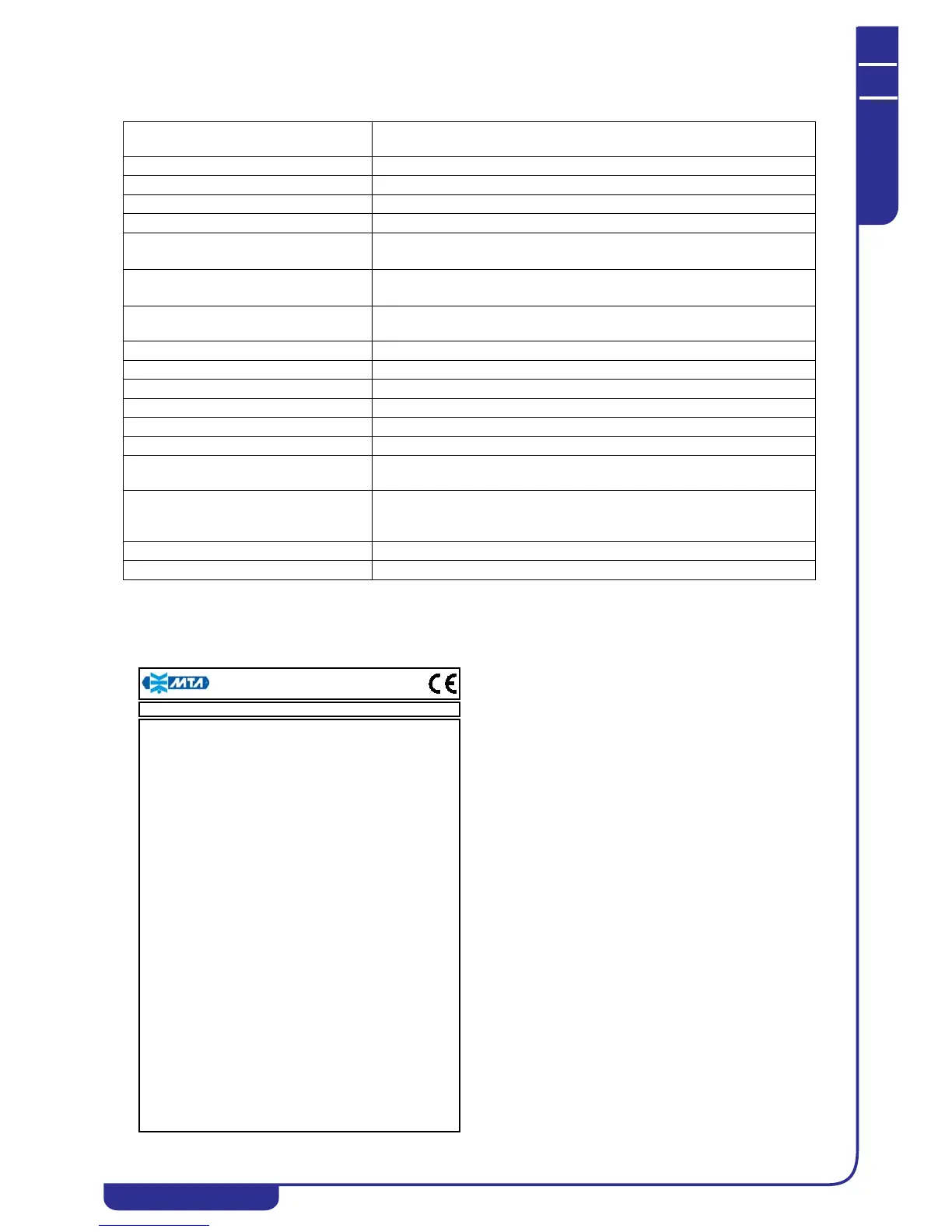

List:

a) Name of manufacturer

b) Definition of responsibility

c) Type of unit

d) Model of the unit

e) Serial or construction number of the unit

f) Directives and standards

g) PED

h) Officer responsible for technical file

i) Particulars of the officer responsible for the technical file

j) Place and date

- CEI EN 61000-6-3 : 2007-11

- CEI EN 61000-6-2 : 2006-10

- CEI EN 61000-6-4 : 2007-11

g) inoltre è stata progettata, costruita e ispezionata conformemente

ai requisiti richiesti dalla Direttiva PED 2014/68/UE

-EN 378

x l’insieme ricade in categoria:

x la procedura di valutazione di conformità utilizzata è secondo il modulo:

(rif. Allegati II e III della Direttiva 2014/68/UE)

x l’organismo notificato incaricato della sorveglianza del sistema di qualità:

x estremi dell'Attestato di approvazione del sistema qualità:

x la macchina è considerata insieme ai fini della direttiva PED. Le attrezzature in pressione che la

compongono e le relative procedure di valutazione di conformità sono le seguenti:

Loading...

Loading...