OPERATING AND MAINTENANCE MANUAL

Risk analysis: residual risk

HAS T 070÷140

98

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

ENGLISH

EN

CHAPTER 10

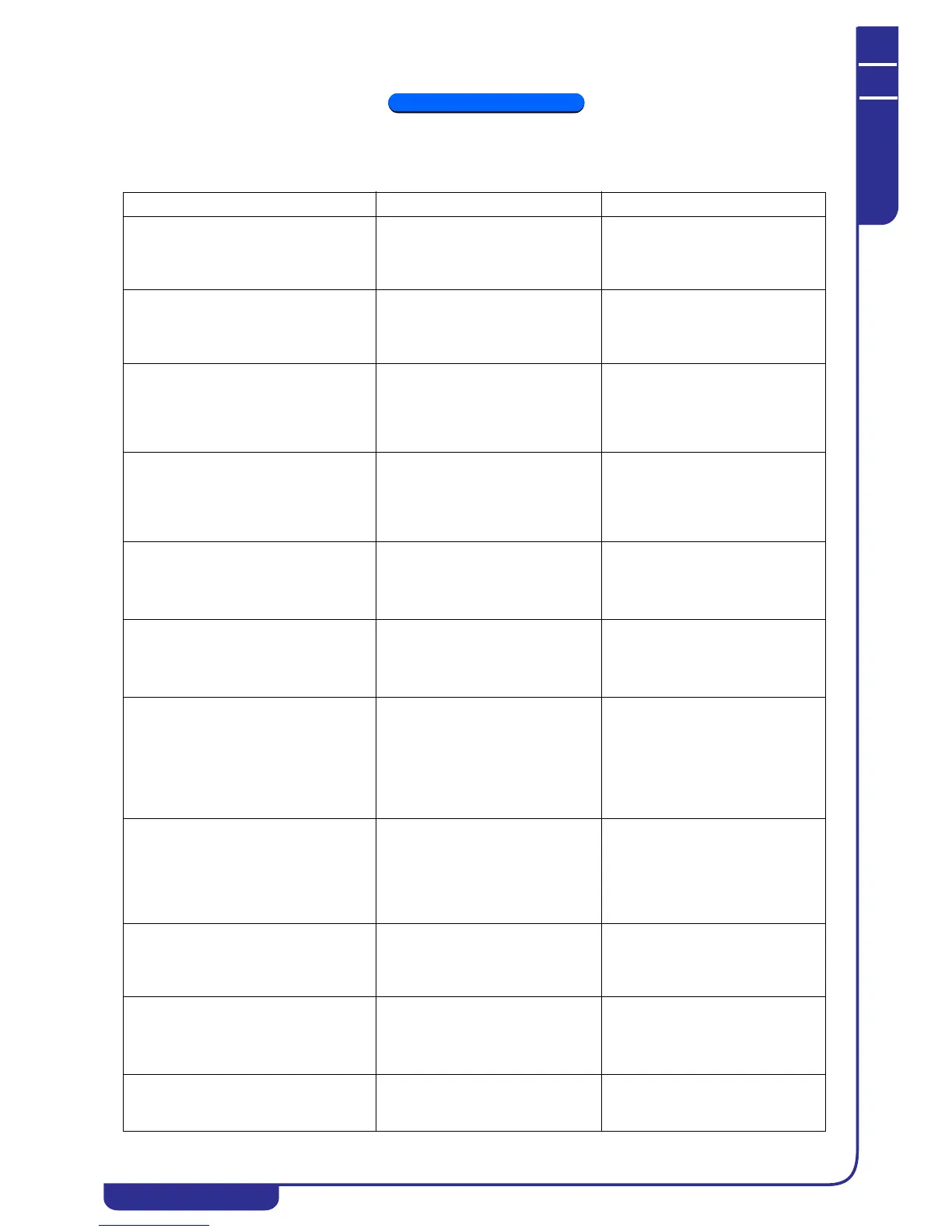

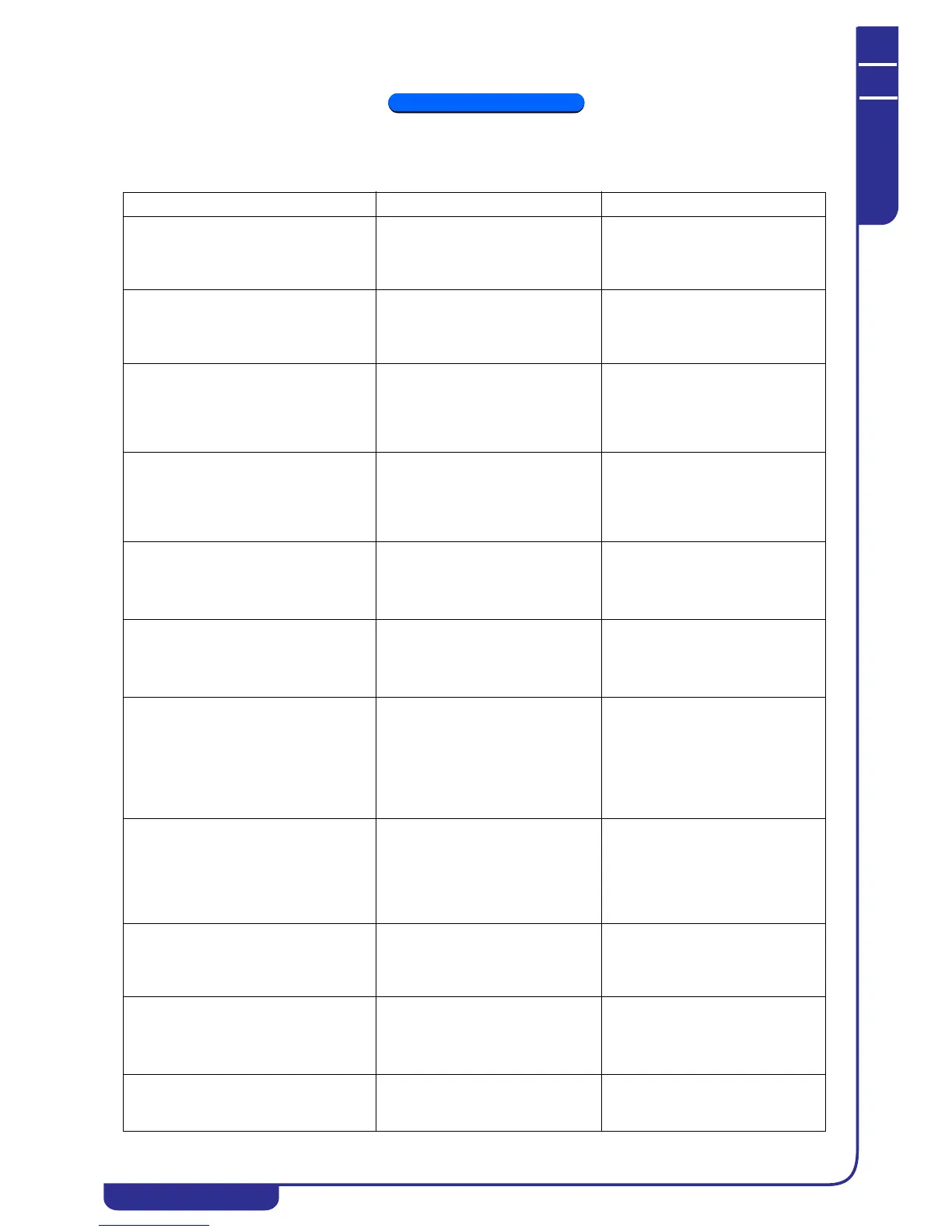

RISK ANALYSIS: RESIDUAL RISK

Description of risk: Effect: User instructions:

1. Risk of crushing Falling of machine onto persons and/

or crushing of limbs.

Use lifting equipment suited to the

task in hand, to be performed by

qualified personnel with reference to

the labelling instructions and manual.

2. Risk of cutting and detachment caused

by sheets or profiles in general.

Risk of cutting upper limbs on sharp

edges caused by shearing of sheets or

saw cutting of profiles.

Strictly observe all manual

instructions. Chapter 2 “Safety”;

Chapter 4 “Installation” and Chapter

8 “Operation and maintenance”.

3. Risk of cutting or detachment due to

the finned surface of air-cooled

condensers.

Risk of cutting upper limbs. Strictly observe all manual

instructions. Chapter 1 “General

information”; Chapter 2 “Safety” and

Chapter 8 “Operation and

maintenance”.

4. Risk of cutting or detachment due to

fan blades.

Risk of cutting or detachment. Strictly observe all manual

instructions. Chapter 1 “General

information”; Chapter 2 “Safety” and

Chapter 8 “Operation and

maintenance”.

5. Risk of high pressure fluid ejection

from pipelines and/or pressure tanks in

cooling circuit due to accidental

bursting.

Contact of body parts with refrigerant

gas or parts of cooling circuit

pipelines launched at high speed.

Strictly observe all manual

instructions. Chapter 2 “Safety” and

Chapter 4 “Installation”

6. Risk of high pressure fluid ejection

from pipelines and/or pressure tanks in

cooling circuit due to design pressure

values being exceeded.

Contact of body parts with refrigerant

gas or parts of cooling circuit

pipelines launched at high speed.

Strictly observe all manual

instructions. Chapter 2 “Safety”;

Chapter 4 “Installation” and Chapter

8 “Operation and maintenance”

7. Risk of high pressure fluid ejection

from pipelines and/or pressure tanks in

hydraulic circuit due to accidental

bursting.

Contact of body parts with fluids or

residual parts of hydraulic circuit

pipelines launched at high speed.

Disconnect the machine from the

electrical mains during interventions

on the hydraulic circuit.

Strictly observe all manual

instructions. Chapter 2 “Safety”;

Chapter 4 “Installation” and Chapter

8 “Operation and maintenance”

8. Risk of high pressure fluid ejection

from pipelines and/or pressure tanks in

hydraulic circuit due to design

pressure values being exceeded.

Contact of body parts with fluids or

residual parts of circuit pipelines

launched at high speed.

Depressurise the machine during

interventions on the hydraulic circuit.

Strictly observe all manual

instructions. Chapter 2 “Safety”;

Chapter 4 “Installation” and Chapter

8 “Operation and maintenance”

9. Electrical hazards due to direct contact

with live parts.

Risk of electrocution and burns. Strictly observe all manual

instructions.

Chapter 2 “Safety” and 4.3.5

“Electrical connections”

10. Electrical hazards due to indirect

contact with parts that are live due to

faults, in particular due to an

insulation fault.

Risk of electrocution and burns. Strictly observe all manual

instructions. Chapter 2 “Safety” and

4.3.5 “Electrical connections”

11. Electrical hazards: electrostatic

phenomena.

Uncontrolled movements by victim of

electrostatic discharge due to contact

Strictly observe all manual

instructions. 4.3.5 “Electrical

connections”

Loading...

Loading...