OPERATING AND MAINTENANCE MANUAL

Chapter 7 - Electronic controller

TAEevo Tech 015÷802 60 Hz UL

100

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

ENGLISH

EN

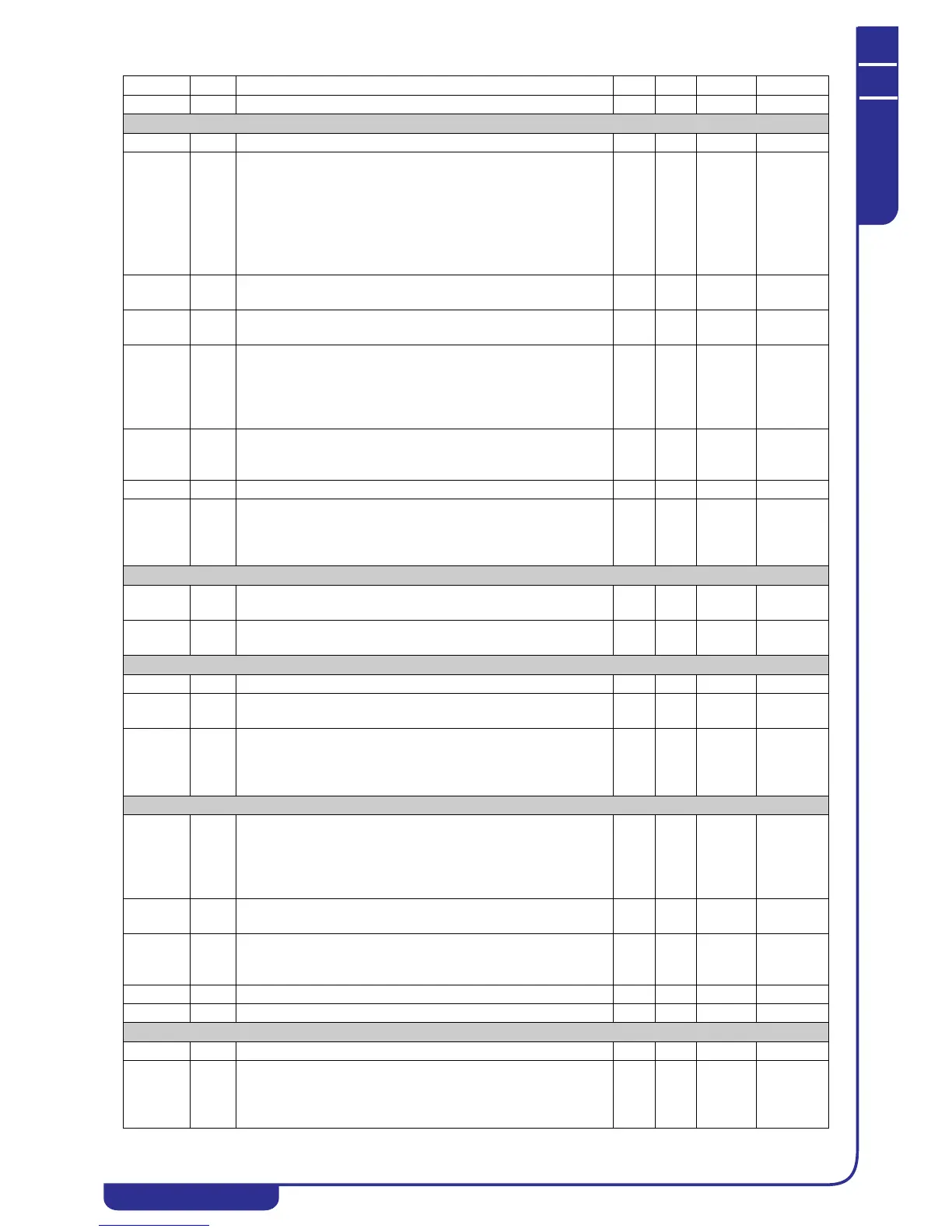

Pr3 C Manufacturer password 0 999

Alarms

AL01 S Low pressure alarm delay from digital / analogue input. 0 250 Sec

AL02 C Parameter AL02 defines operation of the low pressure alarm with

pump down enabled:

AL02= 0 The low pressure alarm is inhibited during the

compressor stop in pump down and with the compressor stopped

AL02

0 The low pressure alarm is inhibited during the

compressor stop in

pump down and with the compressor stopped for the set time.

10 250 10 Sec

AL03 C Analogue input low pressure alarm setpoint. 0.0

0

50.0

725

Bar

Psi

Dec

Int

AL04 C Analogue input low pressure alarm differential. 0.1

1

14.0

203

Bar

Psi

Dec

Int

AL05 C Max. number of trips per hour of digital / analogue input low

pressure alarm.

Reset is always manual if AL05=0.

Reset is always automatic if AL05=16.

Reset switches from automatic to manual if AL05 is from 1 to 15.

016

AL06 C Low temperature / pressure alarm in defrost:

0= Not enabled

1= Enabled

01

AL07 C Low temperature / pressure in defrost alarm delay. 0 250 Sec

AL08 S Low temperature / pressure alarm with unit in remote OFF or

stand-by:

0= Alarm acknowledgement not enabled

1= Alarm acknowledgement enabled

01

High alarm

AL09 C Analogue input high condensing temperature / pressure alarm

setpoint.

0.0

0

50.0

725

Bar

Psi

Dec

int

AL10 C Analogue input high condensing temperature / pressure

differential.

0.1

1

4.0

203

Bar

Psi

Dec

int

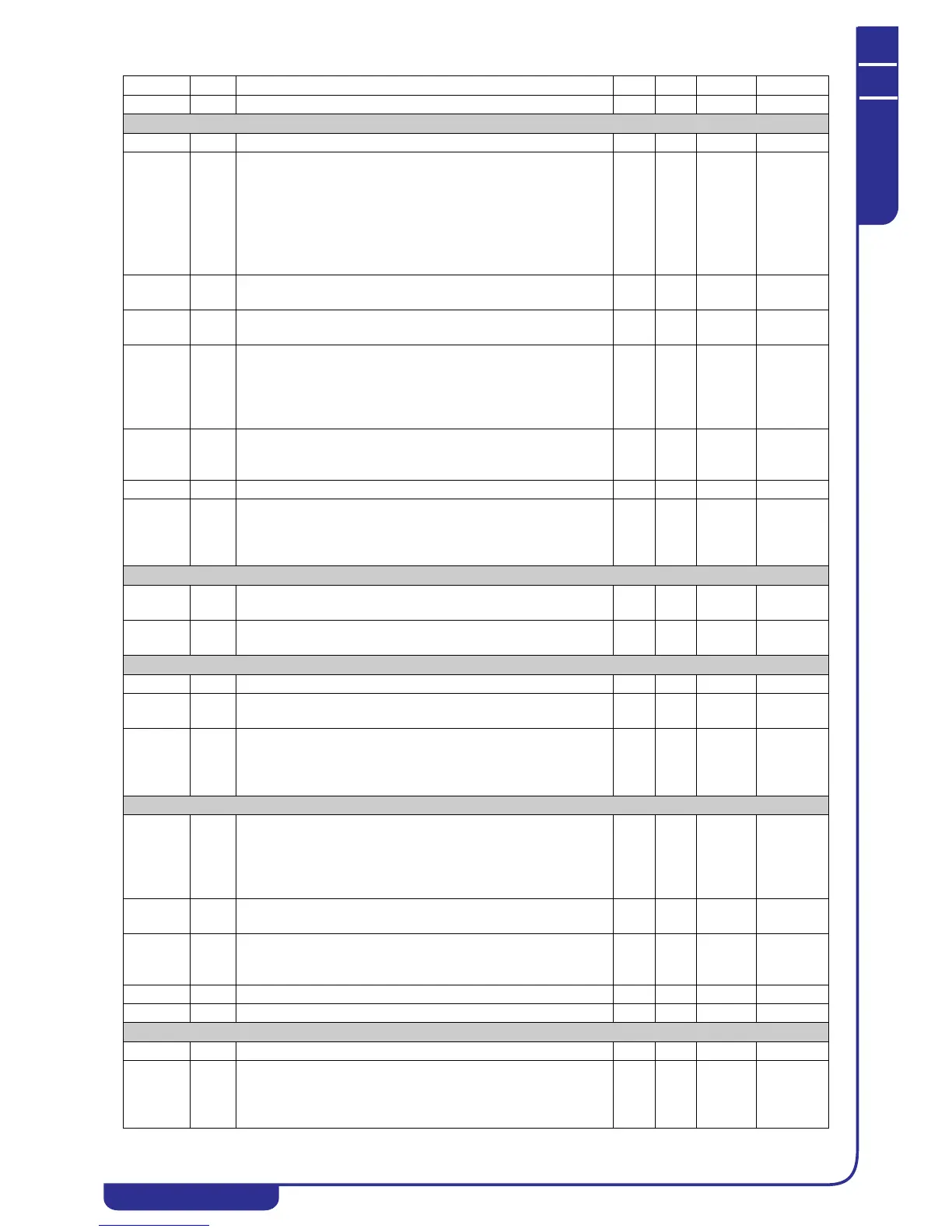

Compressor oil alarm

AL11 C Digital input low oil pressure / level alarm delay. 0 250 Sec

AL12 C Duration of low oil pressure / level alarm input active from digital

input in steady state operation.

0250Sec

AL13 C Max. number of trips per hour of oil low pressure / level alarm.

Reset is always manual if AL13=0.

Reset is always automatic if AL13=16.

Reset switches from automatic to manual if AL13 is from 1 to 15.

016

Level sensor alarm

AL14 C Condenser level sensor operation:

0= Disabled

1= Chiller only

2= Heat pump only

3= Chiller and heat pump

03

AL15 C Delay of evaporator level sensor / delivery fans thermal cutout

alarm from evaporator water pump / delivery fan start.

0250Sec

AL16 C Maximum holding time of evaporator level sensor alarm before

switching to manual and blocking the evaporator water pump, if it

is running.

0250

AL17 C Duration of level sensor / fans thermal cutout input active. 0 250 Sec

AL18 C Duration of level sensor / fans thermal cutout input inactive. 0 250 Sec

Compressors thermal alarm

AL19 C Compressors thermal alarm delay at start 0 250 Sec

AL20 C Compressors thermal cutout max. trips per hour.

Reset is always manual if AL20=0.

Reset is always automatic if AL20=16.

Reset switches from automatic to manual if AL20 is from 1 to 15.

016

Parameter Level Description Min. Max. UM Resolution

Loading...

Loading...