OPERATING AND MAINTENANCE MANUAL

Chapter 7 - Electronic controller

TAEevo Tech 015÷802 60 Hz UL

62

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

ENGLISH

EN

is started. The pump is stopped if the temperature increases above the setpoint + differential, in accordance with the

following diagram:

7.20 ModBus

The supervision system provides the facility to monitor and act on certain of the unit’s parameters by means of a remote

device using the RS485 port. The MODBUS communication mode for the controller features the following characteristics:

Baud Rate = 9600 bps

Data Bit = 8 bit

Parity = None

Stop Bit = 1

Start/stop= 4milliseconds of silence (approximately 3 characters)

Minimum time-out = 500 ms

For further information refer to the specific manual.

7.21 Automatic restart

In case of a power loss, when power is restored the unit will be ON if it was ON at the time of power loss, and OFF if it was

OFF.

7.22 Control with LCD graphic display

On the models TAEevo Tech 015÷351 the electronic control unit is installed on the door of the electrical panel, while on

models TAEevo Tech 381÷802 it is fitted inside the electrical panel while the door is equipped with LCD graphic display.

To convert the semi-graphic LCD display on the door of the electrical panel (mod. TAEevo Tech 381÷802) to remote control,

the relevant remote control kit must be ordered.

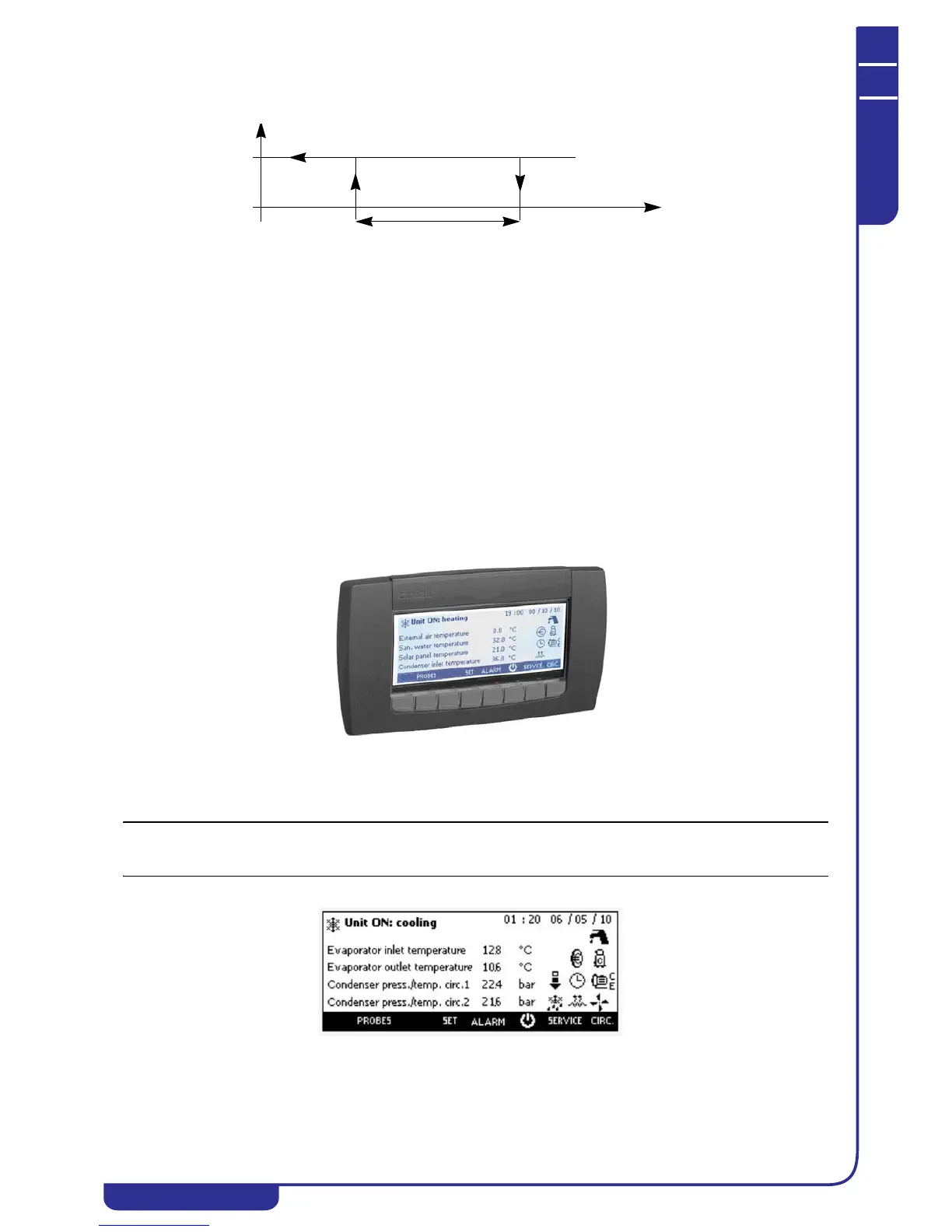

In the main visualization it is possible to read:

• status of the unit: cooling, heating, remote OFF or STD-BY

• 4 probes value; it is possible to manage 4 lines to visualize the probe temperature / pressure (parameters

dP06..dP09)

LCD graphic display TAEevo Tech 381÷802

Loading...

Loading...