OPERATING AND MAINTENANCE MANUAL

Chapter 9 - Operation and maintenance

TAEevo Tech 015÷802 60 Hz UL

186

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

ENGLISH

EN

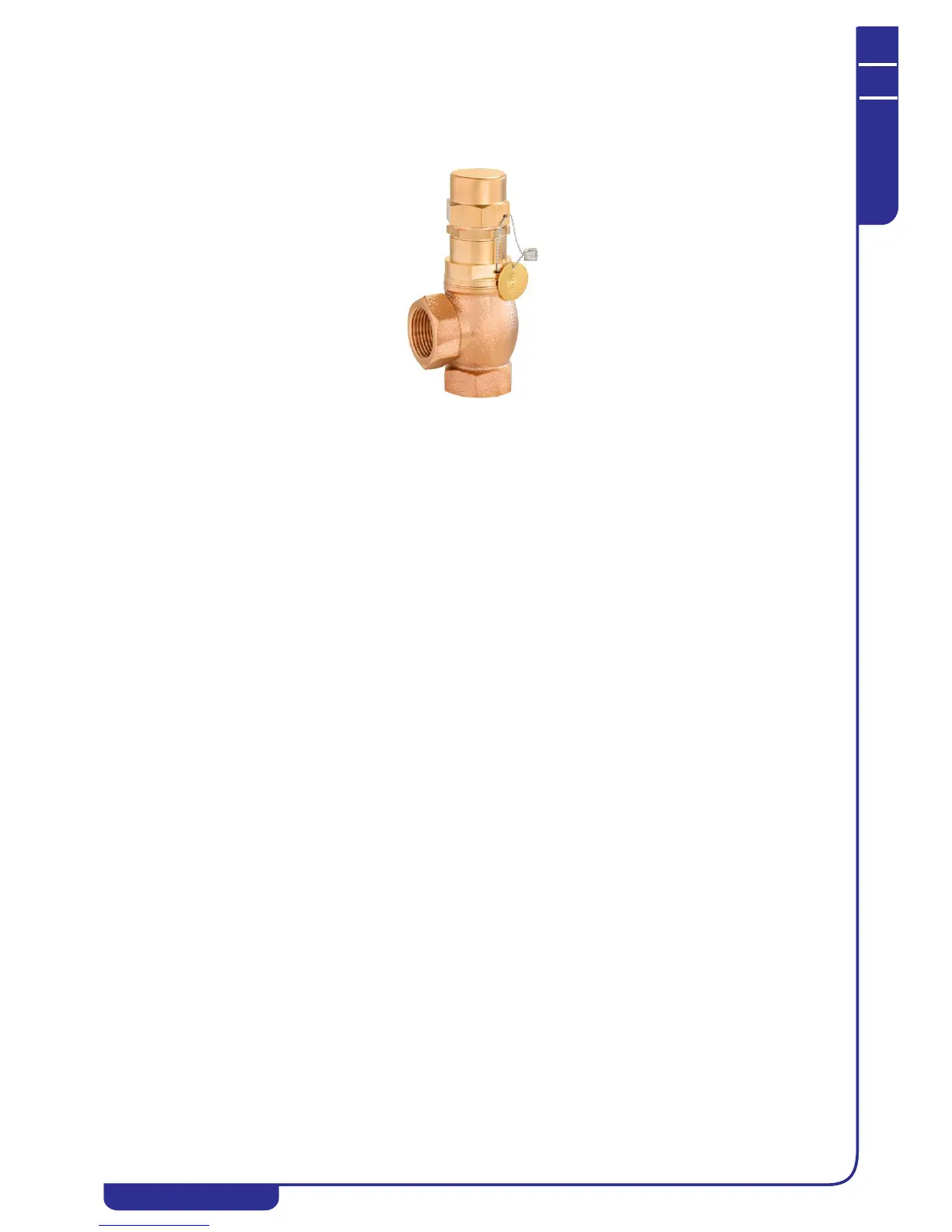

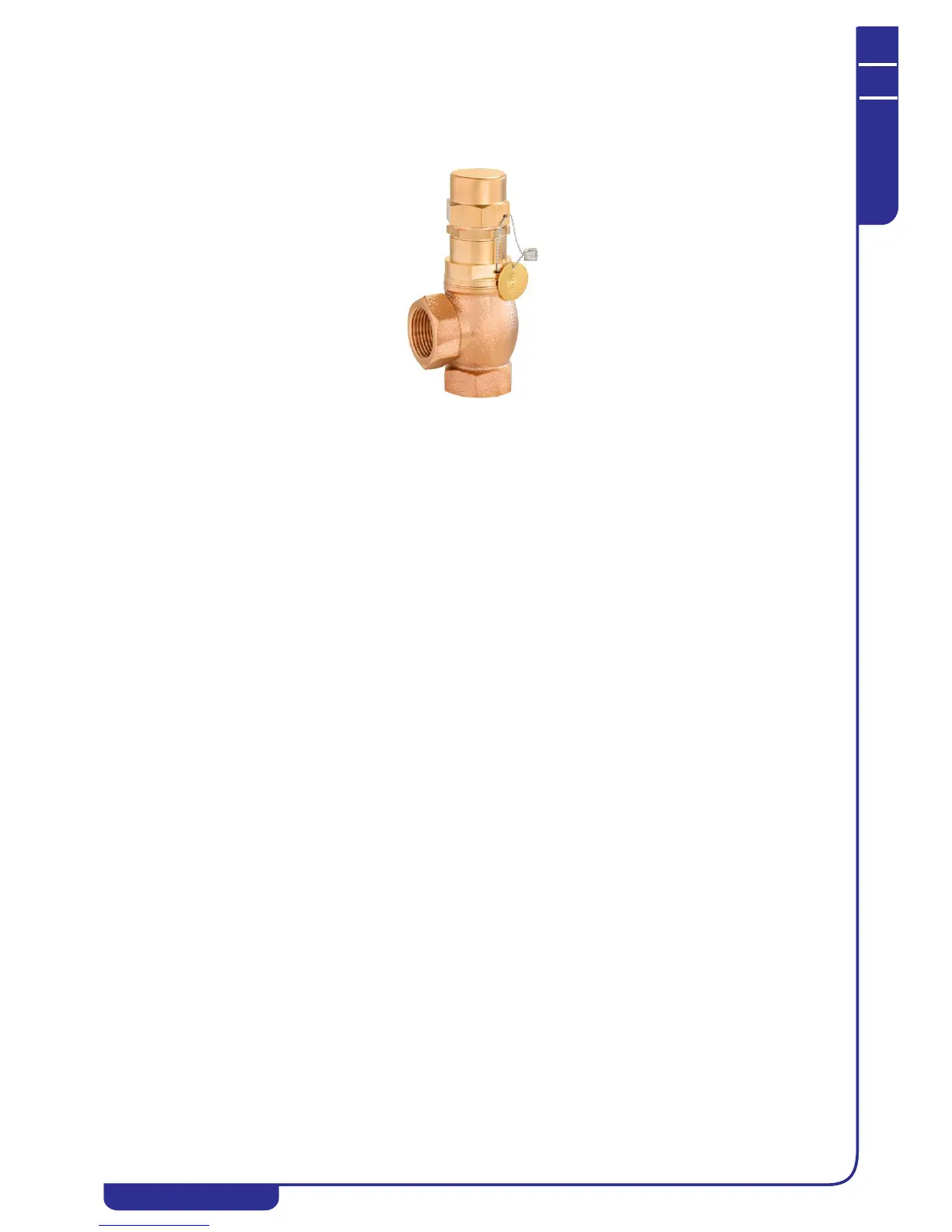

9.5 Pressure limiting valve (option)

The pressure limiting valve is factory set, according to the pump nominal flow operating at a standard voltage of 460V/3Ph/

60Hz.

Before using the unit it is necessary to set the limiting valve according to the customer plant nominal flow and according to

the power supply.

To set the pressure limiting valve it is necessary to follow the procedure below.

9.5.1 General notes of safety

• Only use the valve:

- for the intended purpose

- in satisfactory condition

- with respect for safety and potential hazards.

• Always observe the installation instructions.

• Faults that may impair safety must be addressed immediately.

• The valves are exclusively intended for the application area stated in these installation instructions. Any other

or further use is not valid as the intended use.

• The manufacturer’s warranty for the setting of the valve shall be null and void if the sealed cover is removed.

• All assembly work is to be carried out by authorized specialist staff.

9.5.2 General notes

Overflow valves and pressure limiting valves are high-quality fittings which require a particularly careful handling. The

sealing surfaces are precision-machined at the seat and cone to attain the required tightness. Always avoid the penetration of

foreign particles into the valve during assembly and during the operation. The tightness of a pressure limiting / overflow

valve can be impaired when using hemp, Teflon tape, as well as through welding beads, among other things. Also rough

handling of the finished valve during storage, transport and assembly can result in a valve leaking. If the valves are painted,

make sure that the sliding parts do not come into contact with the paint.

9.5.3 Range of application

As pressure limiting valve (proportional safety valve) for non-adhesive liquids, gas, steam for protection against excess

pressure in pressure tanks or steam boilers as well as pressure-holding equipment parts for pressure devices in compliance

with the EC pressure equipment directive.

As overflow valve (only the gastight versions tGFO) for non-adhesive liquids, gas and steam for pressure limitation and/or

regulation, for protection of pumps and as bypass valve. Overflow valves can also be used if there is counterpressure.

For details on the range of application of the individual versions please refer to the datasheets of the manufacturer.

9.5.4 Installation and assembly

To ensure a satisfactory operation of the valves they must be assembled in such a way that the safety valve is not exposed to

any impermissible static, dynamic or thermal loads.

The installation has to be flushed before installing the valve. If an installation is not sufficiently cleaned or the valve is

installed improperly, the valve may leak even the first time it responds.

Appropriate safety measures must be taken at the place of installation of the valves if the medium that discharges upon

actuation of the valve can lead to direct or indirect hazards to people or the environment.

Pressure limiting valves are to be installed vertically, if possible, and with the bonnet pointing upward. A different

installation position must be clarified with the manufacturer.

Overflow valves (618 tGFO) can be installed in any position. The function of the valves is guaranteed in every position.

During assembly always make sure not to apply any force when fastening the connecting thread and not to screw it in

too far, as this could otherwise damage the seat of the valve. Do not allow sealing material such as hemp or Teflon to

penetrate into the valve.

Loading...

Loading...