OPERATING AND MAINTENANCE MANUAL

Chapter 4 - Description

TAEevo Tech 015÷802 60 Hz UL

22

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

ENGLISH

EN

4.8 Cabinet

The entire plinth, the uprights, and the outer panels are made of galvanized carbon steel sheet and are assembled by means of

screws and/or rivets. All panels undergo phosphor degreasing treatment followed by epoxy polyester power coating.

The frame is designed to allow easy access to all components of the unit.

4.9 Materials in contact with the liquid to be cooled

Standard chillers: carbon steel, copper, aluminium, zinc, brass, stainless steel and plastic materials

specifically:

• evaporator with copper tubes, aluminium fins and galvanized sheet metal shoulders;

• carbon steel tank.

Chillers with non-ferrous hydraulic circuit (TAEevo Tech 015÷401): stainless steel (AISI 304), copper, brass and plastic

materials.

Specifically:

• with copper tubes and fins and brass shoulders;

• tank in AISI 304 stainless steel.

The pump mechanical seals are in silicon carbide/silicon carbide/EPDM.

4.10 Overall dimensions and minimum clearances with

respect to walls

See the enclosed electrical diagrams.

4.11 Electrical circuit

Refer to Chapter 5 “Installation” for information on electrical hook-ups and consult the attached diagrams.

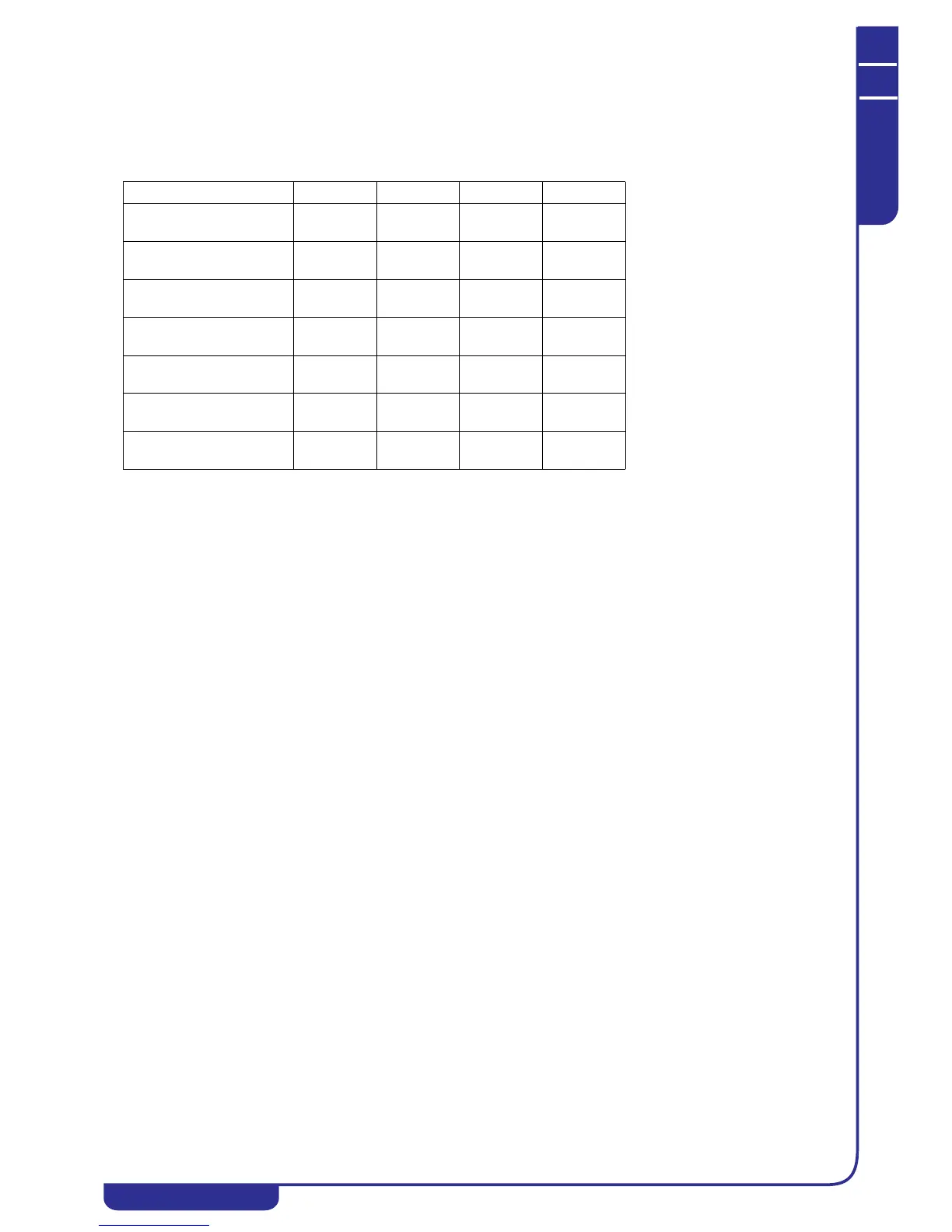

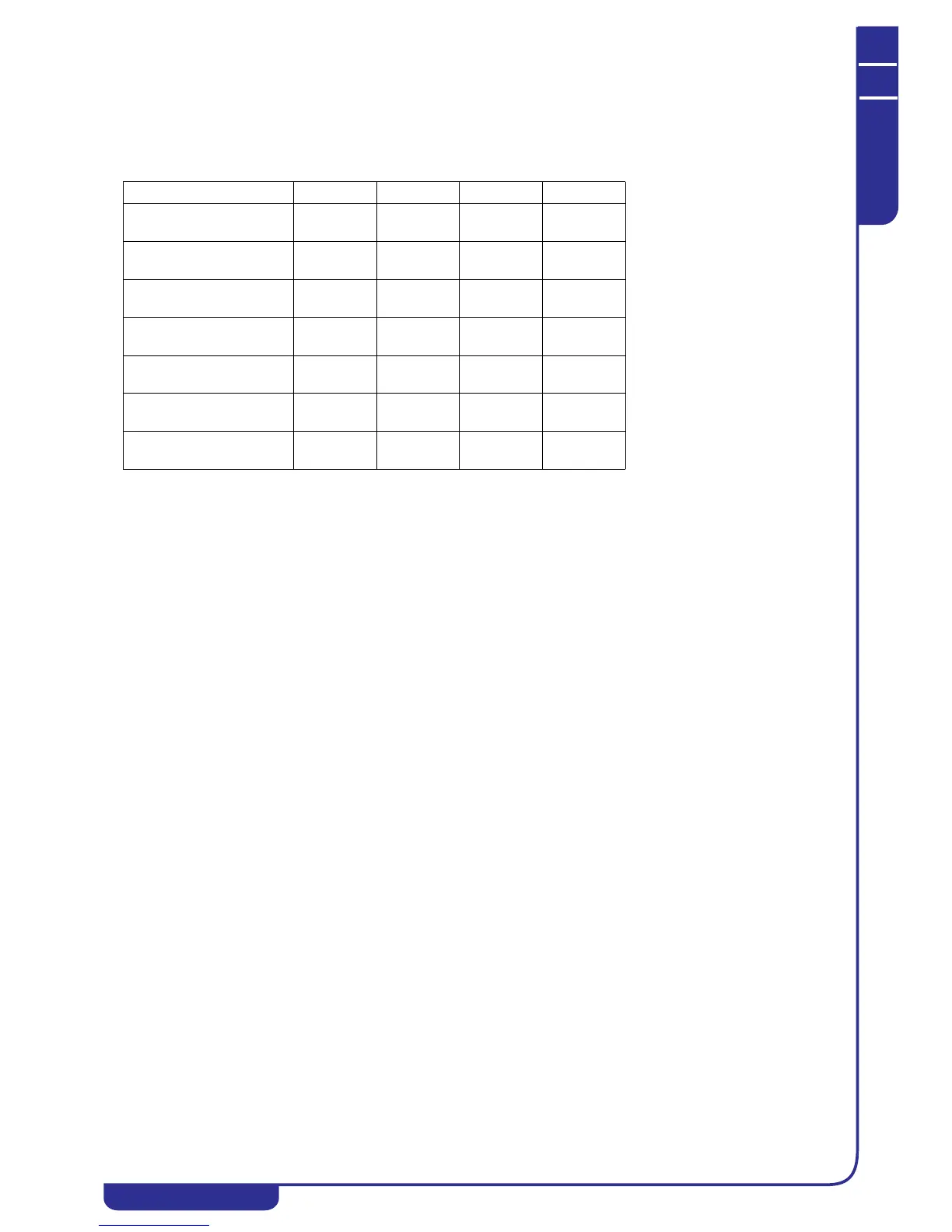

Model Width Depth Height

TAEevo Tech 015÷020

(mm)

(in)

560

22

1265

49.8

794

31.2

TAEevo Tech 031÷051

(mm)

(in)

660

26

1310

51.6

1400

55.1

TAEevo Tech 081÷161

(mm)

(in)

760

29.9

1865

73.4

1447

57

TAEevo Tech 201÷351

(mm)

(in)

865

34

2255

88.8

2065

81.3

TAEevo Tech 381÷401

(mm)

(in)

1150

45.2

2790

110

2091

82.3

TAEevo Tech 402÷602

(mm)

(in)

1255

49.4

3295

129.7

2140

84.2

TAEevo Tech 702÷802

(mm)

(in)

1251

49.2

3350

131.9

2153

84.7

Loading...

Loading...