OPERATING AND MAINTENANCE MANUAL

Chapter 7 - Electronic controller

TAEevo Tech 015÷802 60 Hz UL

50

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

ENGLISH

EN

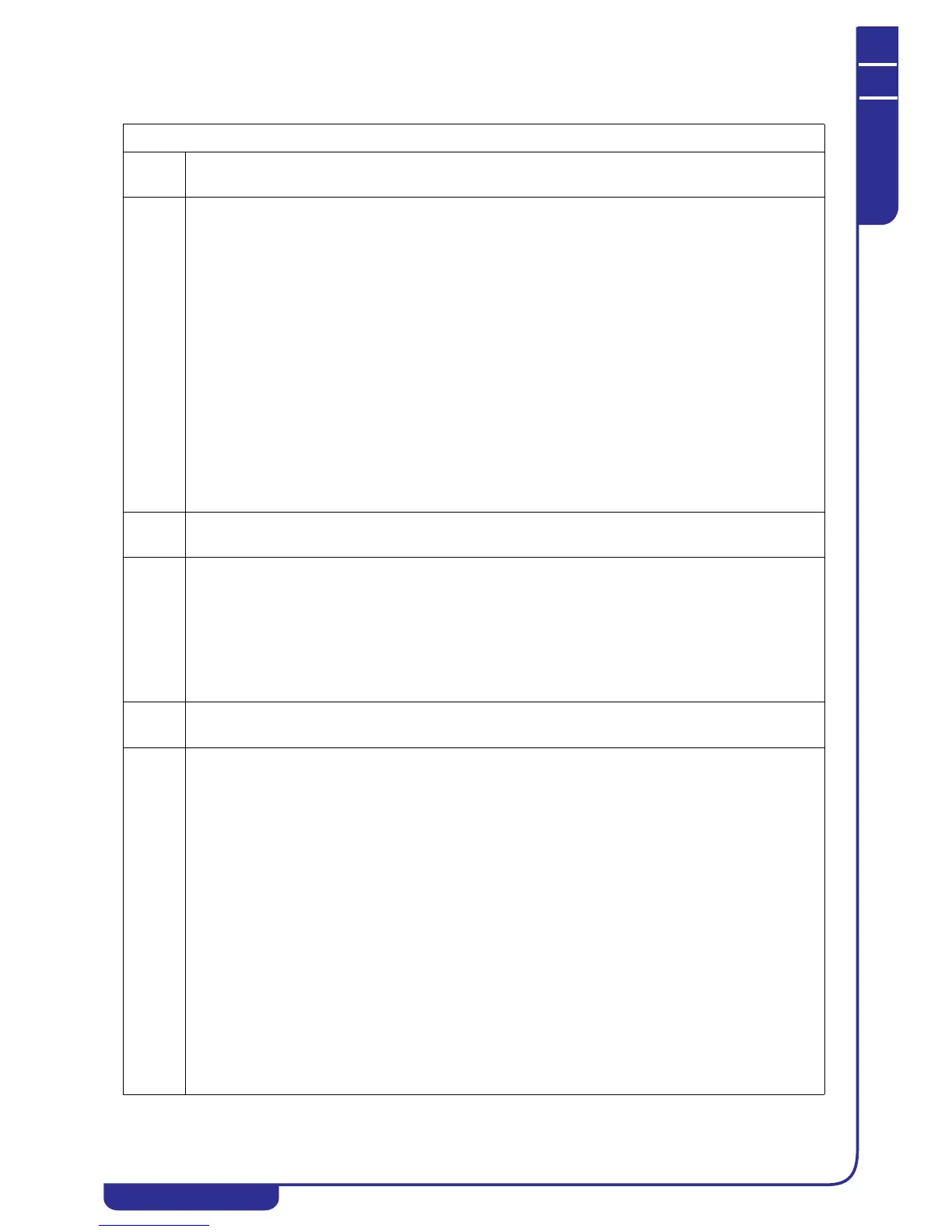

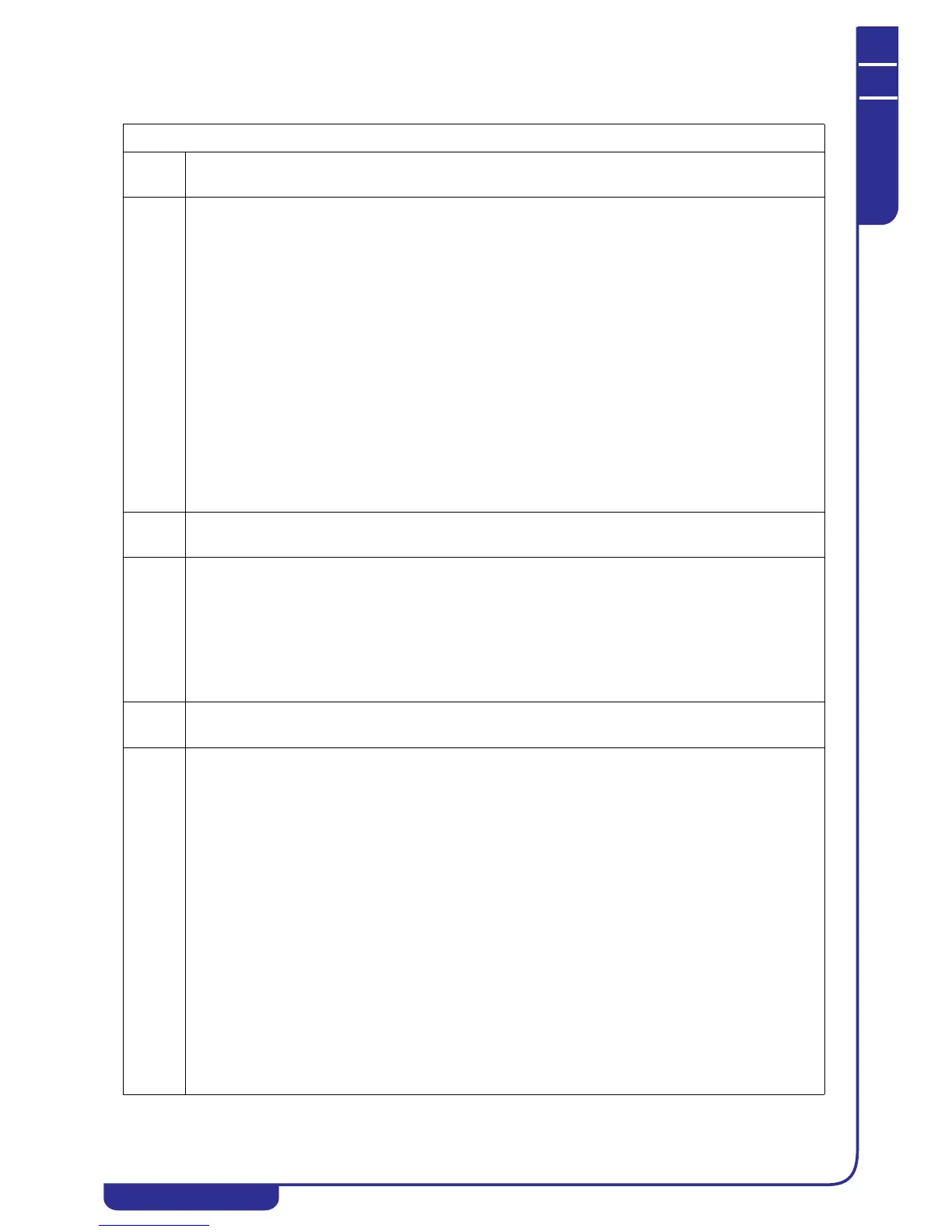

7.11.24 Unit configuration alarm

Display labels meaning

ACF1 Unit configured as heat pump and circuit inversion valve not configured

incorrect combination in values of defrost parameter (dF22/23)

ACF2 Unit configured for ON/OFF or proportional condensing control without configuration of the competent probe

(1 probe per circuit if separate condensing, at least 1 probe if single condensing).

In case of proportional control at least one of the following rules is not observed:

• FA09 + FA11 + FA12 < FA10

• FA12 < FA13

• FA07 < FA15 < FA08

In case of proportional control at least one of the following rules is not observed:

• FA18 + FA21 + FA20 < FA19

• FA21 < FA22

• FA16 < FA23 < FA17

In case of ON-OFF control the following rule is not observed:

• FA09 < FA10

In case of ON-OFF control with pump enabled the following rule is not observed:

• FA18 < FA19

In case of pump enabled and defrost enabled no condensing / evaporation probe per circuit.

In case of fans control with PWM signal continuous supply has been selected (CF83=0).

In case of step control enabled if step1 is not < step2 < step3 < step 4 in chiller mode / if step 4 is not < step3

< step2 < step 1 in heat pump mode.

ACF3 Two digital / analogue or relays configured with same function or configured without adequate resources

(e.g. compressor 3 thermal cutout configured but compressor 3 not configured).

ACF4 • CF59 = 1 and digital input not configured or CF59 = 2 and no NTC probe configured as

ambient air temperature.

• Unit configured as heat pump only and compressors plant enabled.

• CF03

0 and no condensing unit operation enabling digital input and loads configured.

• CF03

0 and all condensing unit operation enabling digital inputs and cooling / heating

demand configured.

• CF03 0 and capacity demands configured in mode that is incongruent with the configuration

of the compressors / capacity steps relay outputs.

ACF5 If circuit 2 is not configured and the resources have not been configured (pump-down relay, heating elements,

cycle inversion valve, condensing fans, recovery, auxiliary).

ACF6 Total number of compressors in the 2 circuits (CF04 + CF05) is:

•> 4

• > 4 and starting is not direct (CO10

0) or number of capacity steps (CF06) is 0

• > 2 and intermittent valve is enabled with ON times (CO08) and OFF times (CO09)

0

If pump-down operation is configured but in at least one circuit:

• The circuit pump-down solenoid relay is not configured.

• The pump-down is not performed by time and the pump-down pressure switch and circuit

evaporation probe are not configured and pump-down is enabled also in start-up or even the low

pressure switch is not configured

The compressor has been configured by means of parameters CF04 and CF05 but the relative relays have not

been installed:

•Compressor relay

• Valve intermittent when enabled from capacity control ON / OFF times (CO08 / CO09

0)

• or gas by-pass when the function is enabled (by-pass time

0)

• Starting part-winding

• Of capacity control for all capacity steps provided

A relay has been configured:

• Associated with a compressor not enabled by parameters CF04 and CF05

• Valve intermittent when ON or OFF times =0

• Capacity control not envisaged

Loading...

Loading...