OPERATING AND MAINTENANCE MANUAL

Chapter 10 - Troubleshooting

TAEevo Tech 015÷802 60 Hz UL

190

The data in this manual are not binding and they can be modified by the manufacturer without notice. Reproduction of this manual is strictly prohibited

ENGLISH

EN

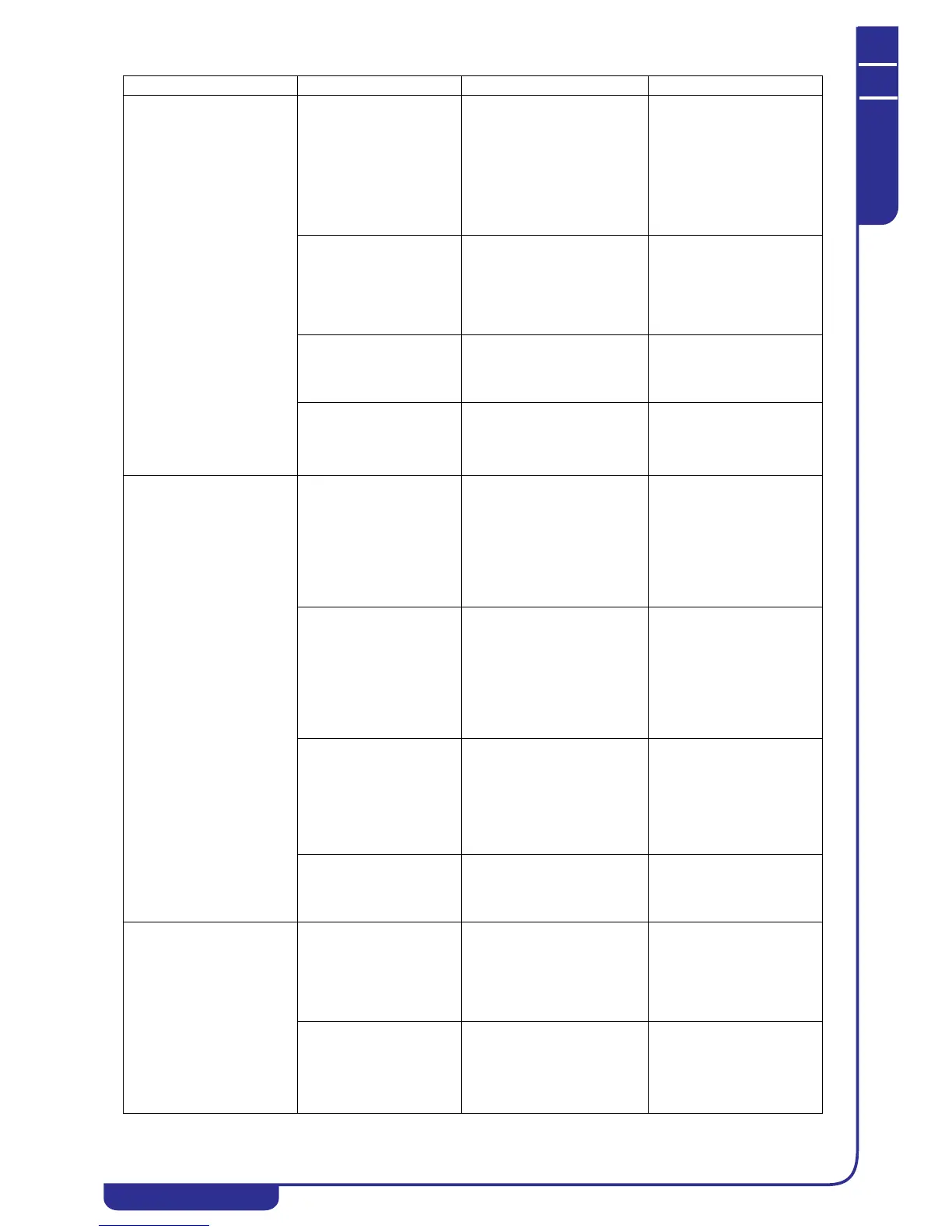

C

The level sensor and/or

flow meter alarm FLOW

trips.

Alarm displayed:

AEFL

C1

Unit upline filter, if

present, is clogged.

C1.1

• Water flow is irregular.

Pressure difference between

inlet and outlet below 25mbar /

0.36 PSI;

• The text AEFL appears on the

display;

• General alarm relay activation.

Clean the filter upline from the

unit, if installed.

Perform the alarm reset

procedure to restart the unit (see

Electronic controller).

C2

The pump does not work

or rotates in the opposite

direction (three-phase

power supply).

C2.1

• See C1.1;

• General alarm relay activation.

Check the pump electrical

supply and, if necessary, invert

two of the phases.

Perform the alarm reset

procedure to restart the unit (see

Electronic controller).

C3

Water inlet-outlet

inverted (units without

hydraulic kit).

C3.1

• See C1.1;

• General alarm relay activation.

Invert water inlet and outlet.

Perform the alarm reset

procedure to restart the unit (see

Electronic controller).

C4

The storage tank has not

been bled correctly.

C4.1

• The text AEFL appears on the

display;

• General alarm relay activation.

Bleed the storage tank via the

relative bleed valve.

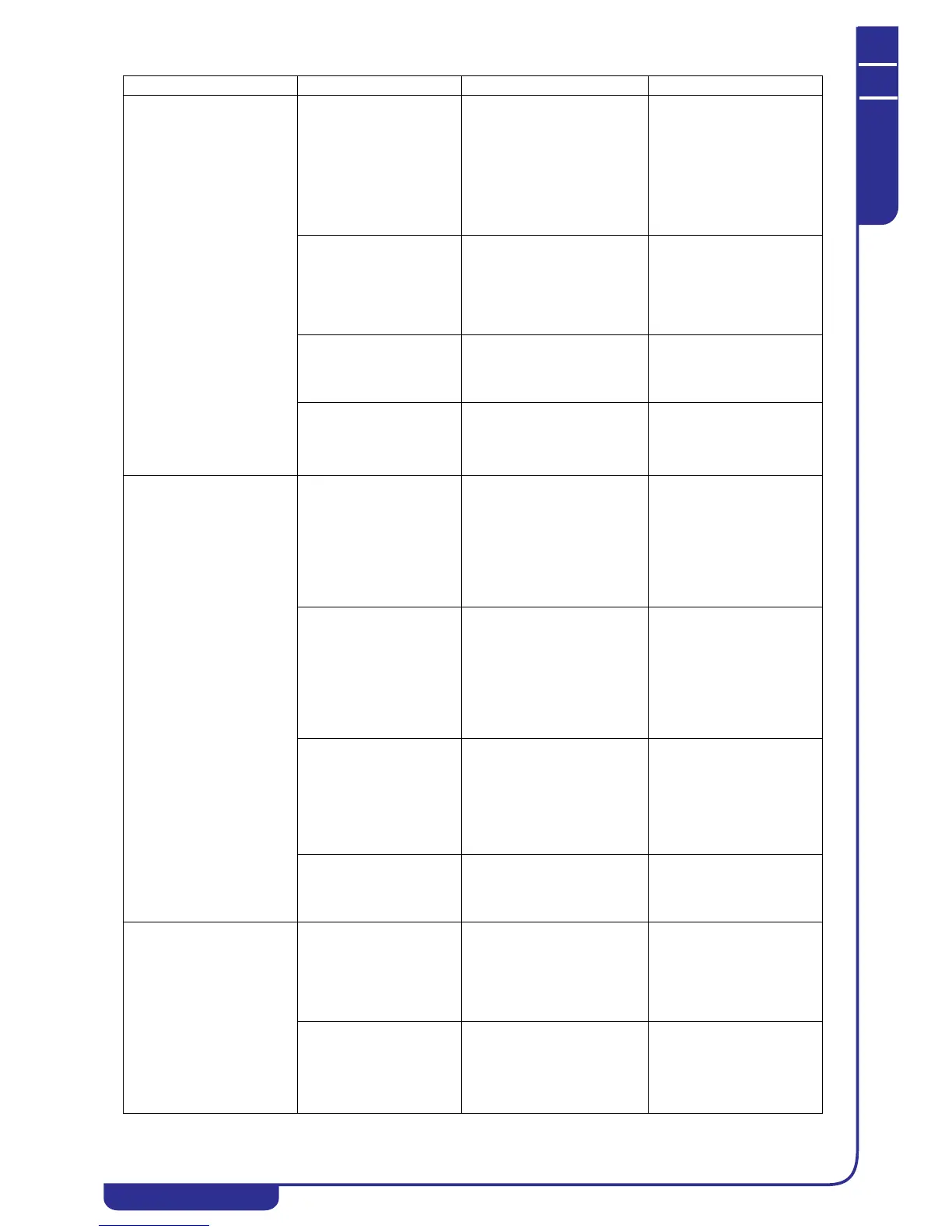

D

High pressure switch (HP)

trip

(TAEevo Tech 015÷401

models only)

Alarm displayed:

b(n)HP

D1

The fan doesn’t work.

D1.1

• Refrigerant compressor stops;

• The text b(n)HP appears on

the display alternating with

value of BTOWT;

• General alarm relay activation;

Repair or replace the fan.

Where fitted, check the circuit

breaker of the fan.

Perform the alarm reset

procedure to restart the unit (see

Electronic controller).

D2

Ambient air temperature

too high.

D2.1

• Ambient air temperature

higher than maximum

permitted value;

• See D1.1.

If the unit is installed in an

enclosed place, reduce ambient

temperature to within the

prescribed limits, for example

by increasing room ventilation.

Perform the alarm reset

procedure to restart the unit (see

Electronic controller).

D3

Recirculation of warm air

due to incorrect

installation.

D3.1

• Condenser cooling air

temperature higher than

maximum permitted value;

• See D1.1.

Change the position of the unit

or the position of any nearby

obstructions in order to prevent

recirculation.

Perform the alarm reset

procedure to restart the unit (see

Electronic controller).

D4

See A3.

D4.1

See D1.1.

Clean the condenser fins.

Perform the alarm reset

procedure to restart the unit (see

Electronic controller).

D5

See A4.

D5.1

See D1.1.

Remove the obstruction from

the front surface of the

compressor.

Perform the alarm reset

procedure to restart the unit (see

Electronic controller).

D6

Thermal load too high.

D6.1

• Water outlet temperature too

high;

• Refrigerant compressor stops;

• General alarm relay activation.

Restore thermal load to within

prescribed limits if possible.

Perform the alarm reset

procedure to restart the unit (see

Electronic controller).

PROBLEM CAUSE SYMPTOM REMEDY

Loading...

Loading...