Ventilation connection

FIGHTER 360P

For the Installer

14

FIGHTER 360P is connected so that all ventilation air

except the kitchen fan passes the evaporator (62) in

the heat pump. The lowest ventilation flow according

to current standards is 0.35 l/s per m

2

floor area. For

optimum heat pump performance the ventilation flow

should not be less than 110 m

3

/h. (31 l/s).

The heat pump's installation area should be ventilated

by at least 36 m

3

/h (10 l/s).

FIGHTER 360P is equipped with a ventilation

opening in the base. As a result, an air flow of about 5

m

3

/h (1,4 l/s) is taken directly from the room where the

heat pump is installed.

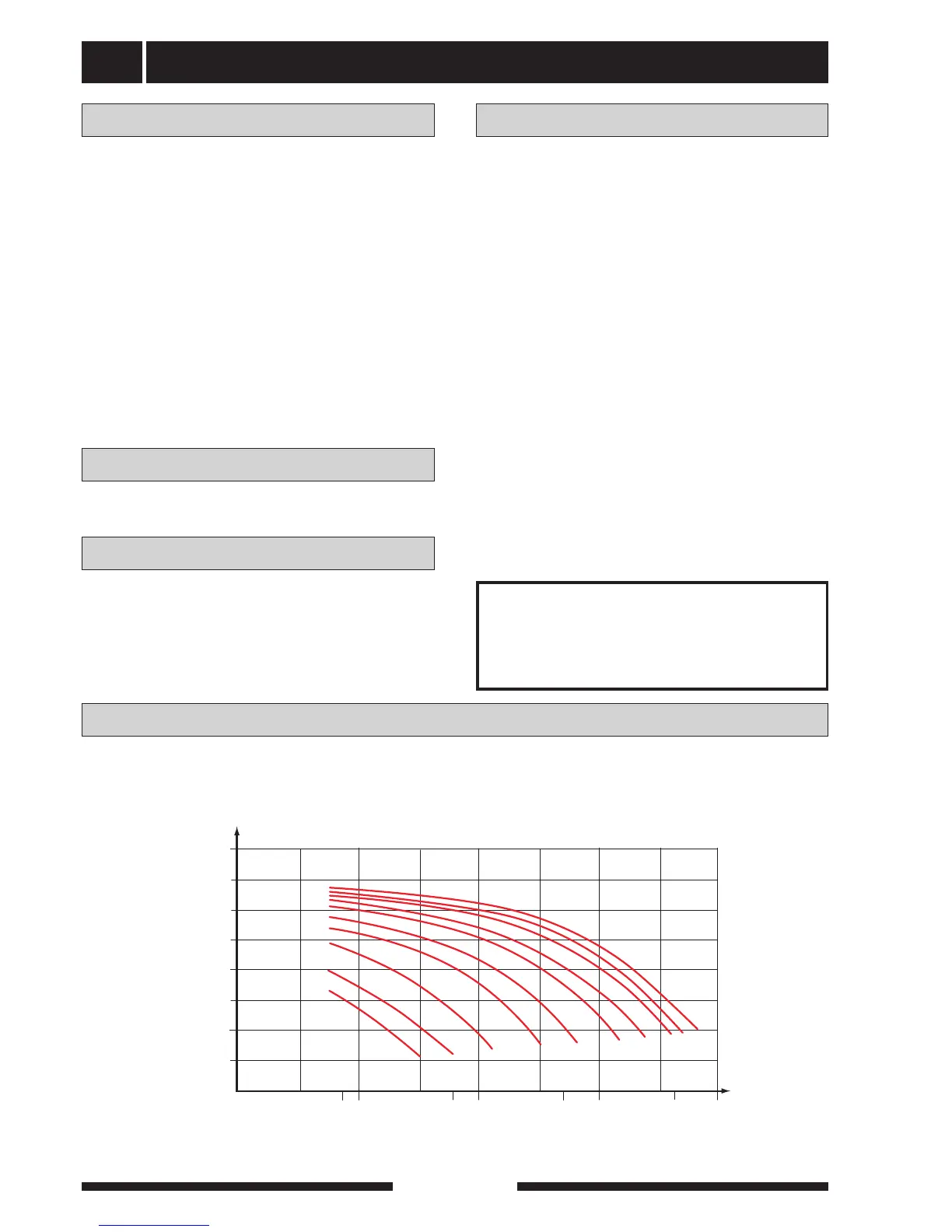

Changing the ventilation capacity is described under

Electrical connection - Setting the fan capacity. See

also Circuit diagram. The numbering of the curves

refers to the numbering on the fan terminal block (22).

To obtain the necessary air exchange in every room of

the house, the exhaust air devices must be correctly

positioned and adjusted. A defective ventilation instal-

lation may lead to reduced heat pump efficiency and

thus poorer operating economy, and may result in

damage to the house.

NOTE!

A duct in a masonry chimney stack

must not be used for extract air.

To prevent fan noise being transferred to the exhaust

air devices, it may be a good idea to install a silencer

in the duct. This is especially important if there are

exhaust air devices in bedrooms.

As the heat pump contains a flammable refrigerant in

the form of propane (R290), the air ducting system

must be earthed. This is done by making a sound elec-

trical connection to the exhaust air and vented air

ducts with the two earthing cables supplied. The cables

must then be connected to the earthing studs on top

of the top cover.

Connections should be made via flexible hoses, which

must be installed so that they are easy to replace. The

extract air duct must be provided with diffusion-tight

insulation over its entire length. Provision must be

made for inspection of the duct. Make sure that there

are no reductions of cross-sectional area in the form

of creases, tight bends etc, since this will reduce the

ventilation capacity. All joins in the ducting must be

sealed and pop-riveted to prevent leakage.

The air duct system should, at a minimum, be of air

tightness class B.

The diagram below shows the available ventilation

capacity.

Fan diagram

Ventilation flow Duct installation

Adjustment

Loading...

Loading...