5238-E P-154

SECTION 7 FIXED CYCLES

[Supplement]

8-15-1. Forward Tapping Cycle (G178)

LE33013R0300900440001

[Programming format]

LE33013R0300900440002

Cycle operation

When the one-point clutch specification is not selected for the M-tool spindle clutch, its start point

is not guaranteed even when a D command is designated.

J : Number of threads

Whenever the number of threads per inch is specified with inch taps, it is convenient to

use J as an indicator, to avoid confusion with metric measurements.

Q : Number of holes (for details, refer to “Repeat Function”).

Q

1

: The axes are positioned at the coordinates (X

1

, C) at the rapid feedrate, and M-tool spindle

rotation is stopped.

Q

2

: The axes are positioned at the cutting start point (Z

0

, -K) at the rapid feedrate.With M-tool

spindle one-point clutch models, the M-tool spindle oscillates after the completion of

positioning at (Z

0

, -K) to engage the clutch.

When a D command had been designated, the M-tool spindle is positioned at point D

along the tapping rotation direction.

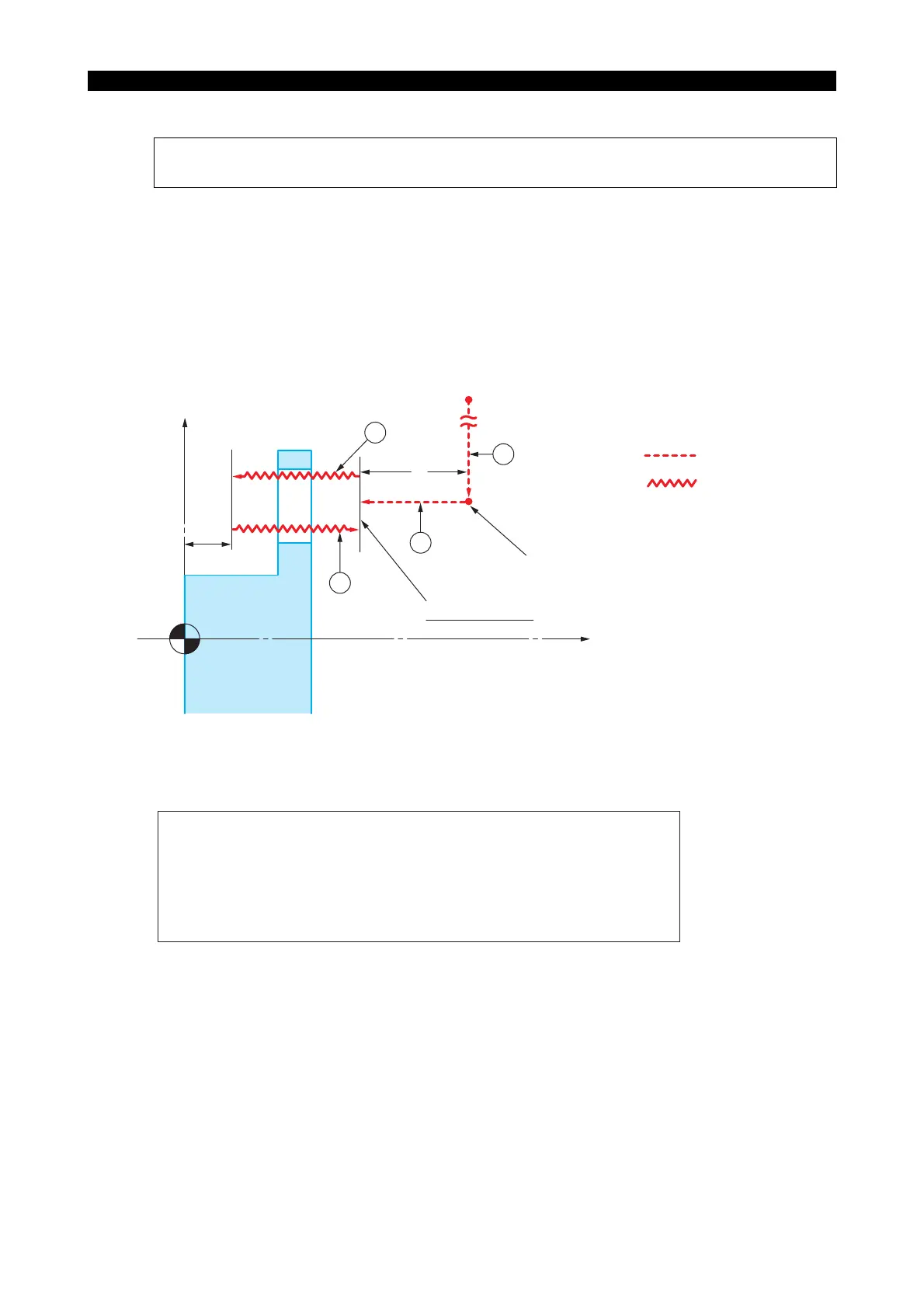

Q1

Q3

Q4

Q2

(X1, Z0)

(X

0, Z0)

K

Z

1

Cutting start point

Rapid feed

Cutting feed

(synchronized feed)

Cycle start point

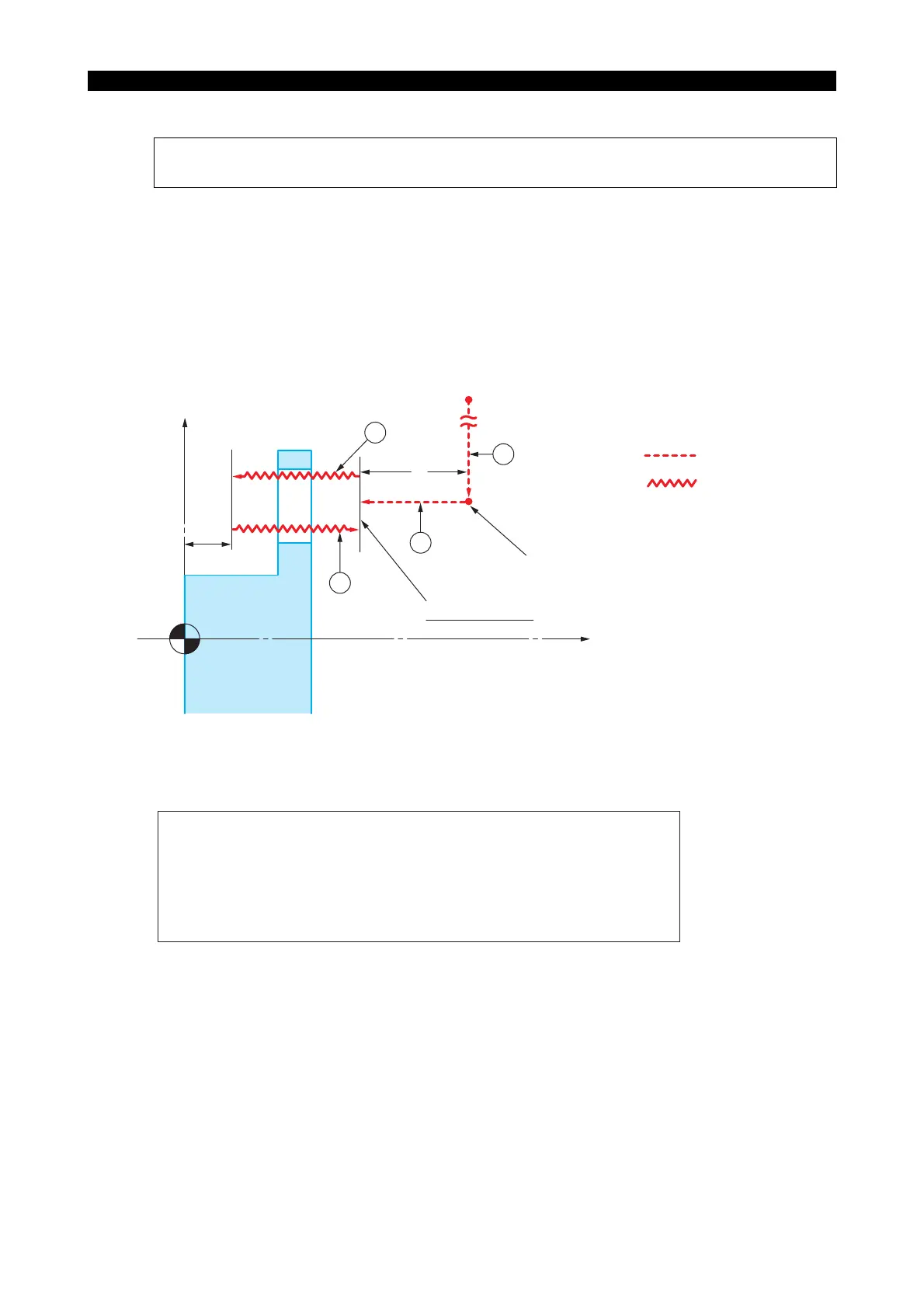

N100

N101

N102

N103

G00

G94

G178

G180

X0

X1

Z0

Z1 C

SB=

KFD

:

:

Loading...

Loading...