5238-E P-103

SECTION 7 FIXED CYCLES

4. Precautions when Programming Thread Cutting Cycles

Observe the following points when programming thread cutting cycles:

• The G codes commanding thread cutting (G31 to G35) cannot be designated in the G96

(constant peripheral speed cutting ON) mode.

• Motion of Thread Cutting Tool

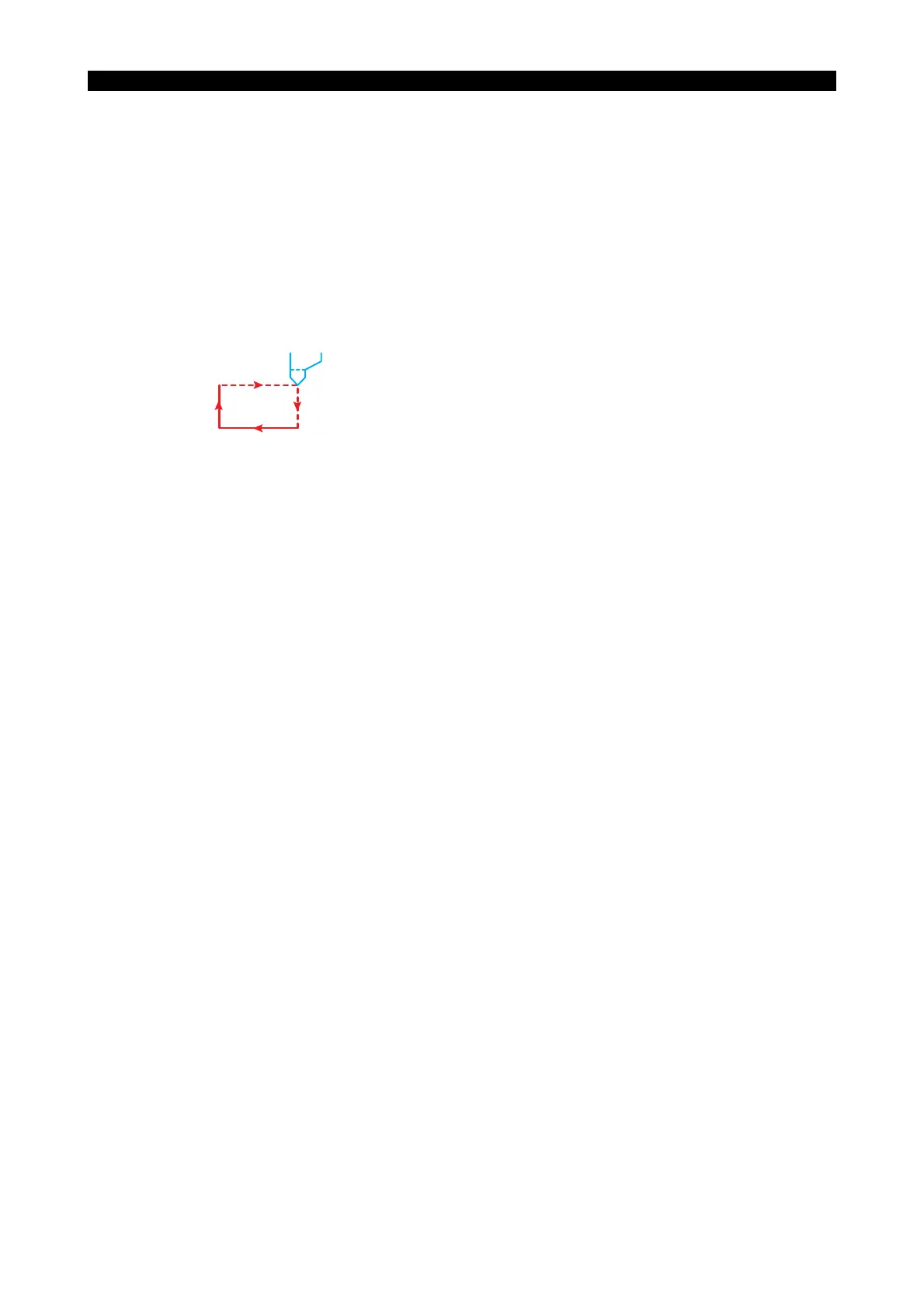

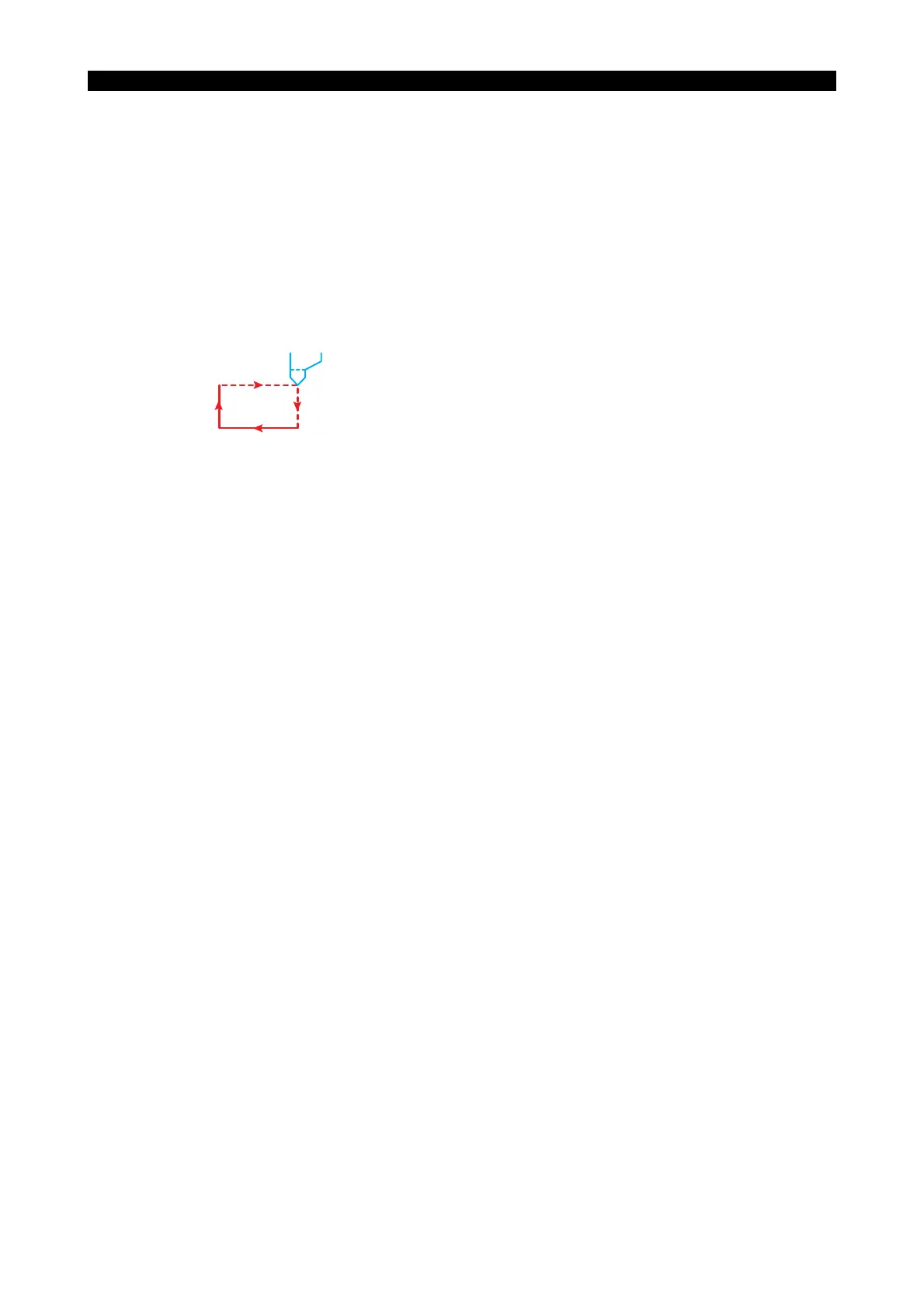

In thread cutting cycles called for by G31, G32 and G33, tool paths a and d are executed at a

rapid feedrate, b at the feedrate specified by an F word, and c at the rate determined by

parameter setting.

LE33013R0300900060001

• Lead of Taper Thread

The lead of a taper thread is parallel to the Z-axis in the G31 and G33 mode, and parallel to the

X-axis in the G32 mode.

In the G34 and G35 modes, an M code is used to designate the direction of thread lead:

M26: Cancelation of M27, parallel to Z-axis

M27: Parallel to X-axis

If no M code is specified in the G34 or G35 mode, the control assumes M26, parallel to the Z-

axis.

• Number of Thread Cutting Passes

Determine the number of thread cutting passes to complete the thread according the workpiece

material, thread lead, etc.

• Spindle Speed Change During Thread Cutting Cycle

If the spindle speed is changed during a thread cutting cycle, it will shift the starting point of the

cycle, damaging the thread being cut.

Therefore, never change spindle speed during thread cutting cycle.

• Feedrate Override

The feedrate override dial is inoperative during a thread cutting cycle.

• Chamfering

Chamfering in thread cutting to produce a thread vanish cone can be programmed by

commanding M23, if required. To cancel this mode, command M22.

M22: Chamfering OFF

M23: Chamfering ON

c

b

a

d

Loading...

Loading...