5238-E P-32

SECTION 3 MATH FUNCTIONS

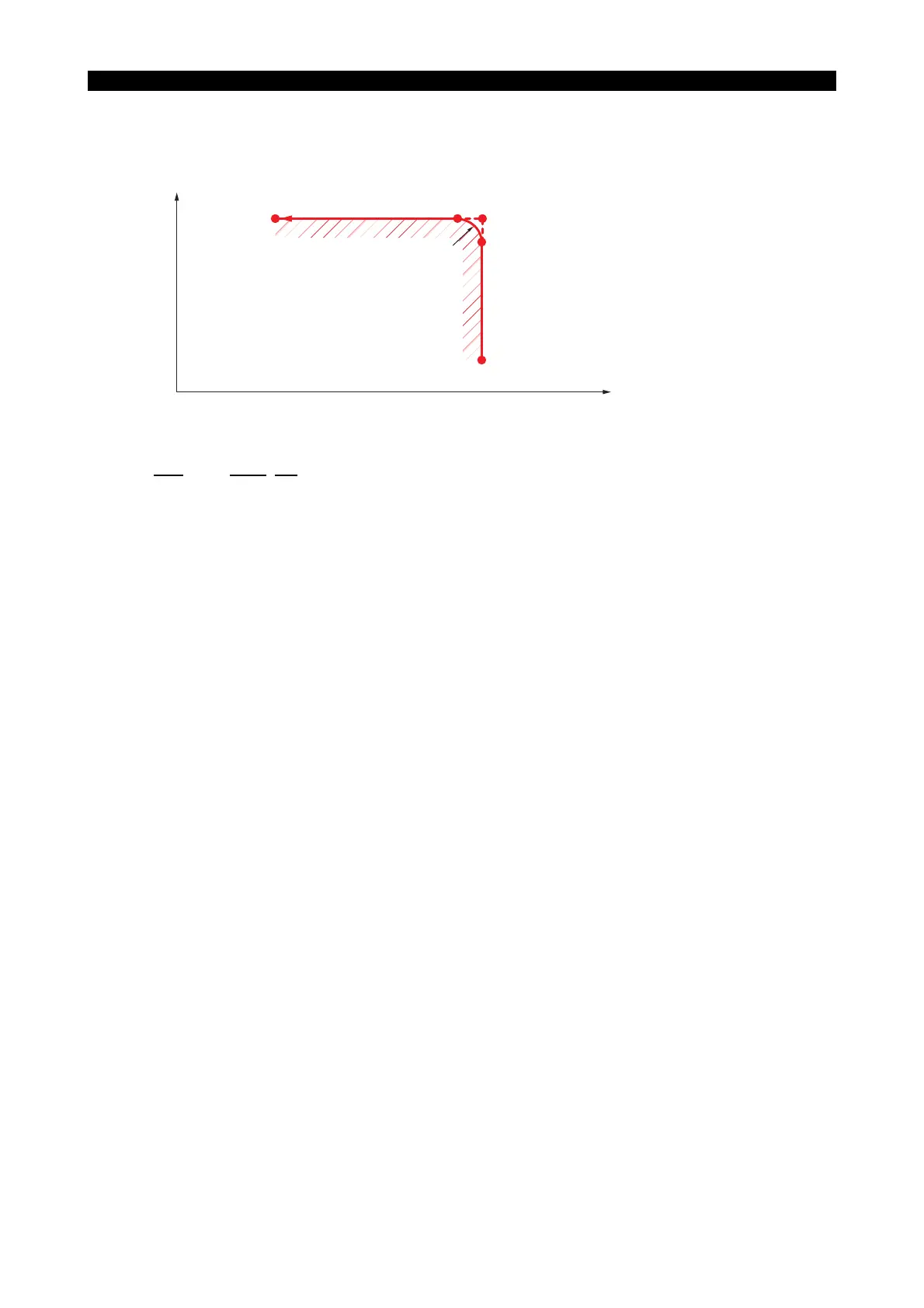

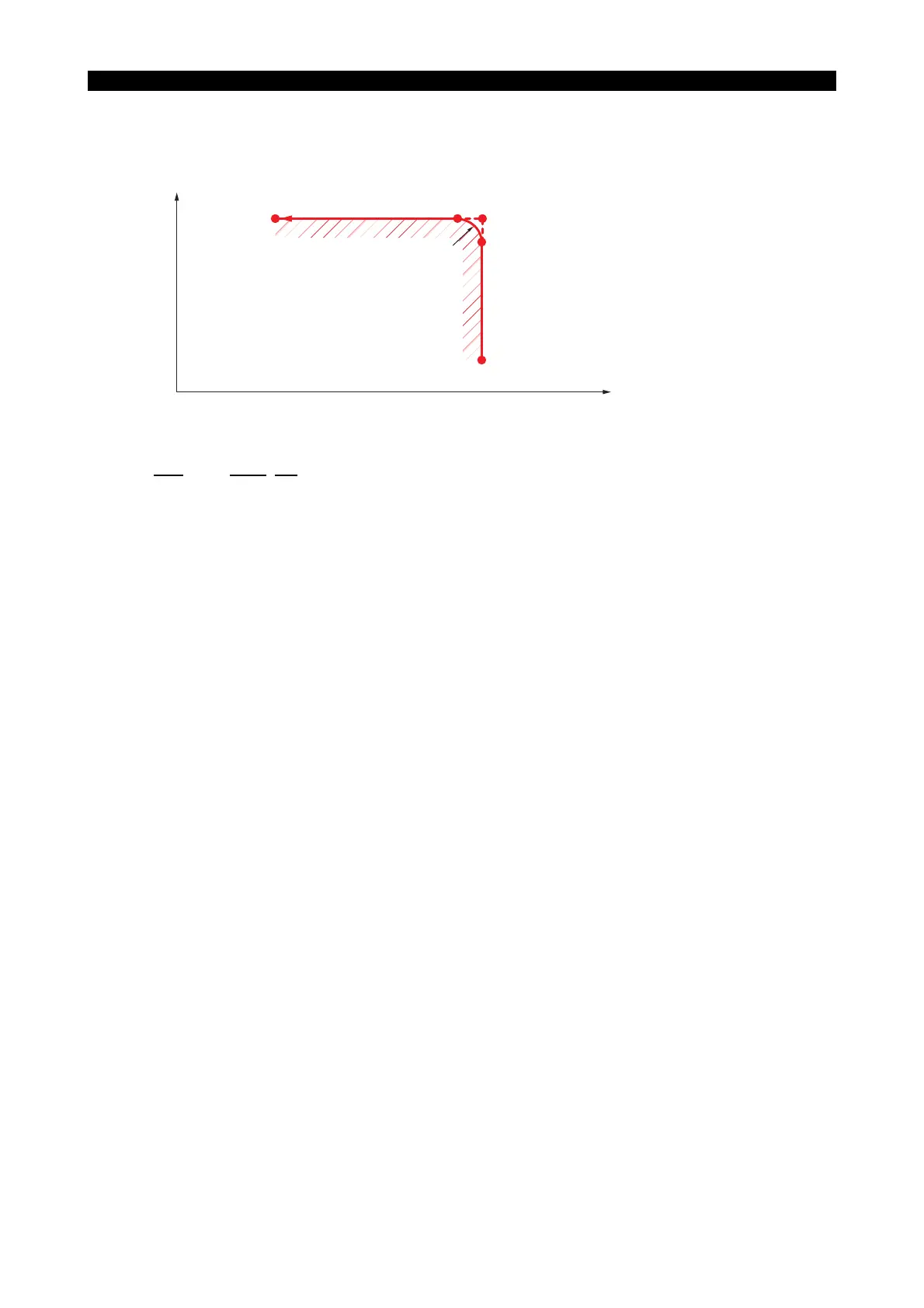

4-2. Rounding (G76)

LE33013R0300500060001

To cut the contour shown above along the points A, B, D and E, program as follows:

G76

G01 X120 L-5 FDD CR

after positioning the cutting tool at point A.

With the commands above, the cutting tool moves from point A to B and then to D, thus

automatically rounding the corner to a radius of 5 mm.

When the coordinates of point E are commanded, the cutting tool moves from point D to point E.

[Details]

• G76 is effective only in the G01 mode. If G76 is specified in a mode other than G01, an alarm

occurs.

• G76 is non-modal and active only in the commanded block.

• The rounding describes a 1/4 circle with the radius specified by an L word.

• If the axis movement dimension specified in the block calling for automatic chamfering (A - C in

the figure above) is smaller than the absolute value of the L word (B - C in the figure above), an

alarm results.

• If the axis movement dimensions specified in the block calling for automatic chamfering are

zero both for X and Z, or if neither X nor Z value is zero in such a block, an alarm occurs.

The block calling for automatic chamfering mode can contain only one dimension word, either X

or Z.

• The automatic chamfering program is effective in:

LAP

Tool nose radius compensation mode

G76 : Specifies rounding of a corner

X120 : X coordinate of Point C

L-5 : Radius of rounding circle

The sign is determined by the direction of axis movement;

"+" when the Z-axis (X-axis) moves in the positive direction after the X-axis (Z-axis)

motion.

"-" when the Z-axis (X-axis) moves in the negative direction after the X-axis (Z-axis)

motion.

+X

B (X110.00, Z120.00)

A (X50.00, Z120.00)

C (X120.00, Z120.00)

(X120.00, Z115.00)

(X120.00, Z50.00)

+Z

5R

E

D

Loading...

Loading...