5238-E P-251

SECTION 10 COORDINATE SYSTEM CONVERSION

SECTION 10 COORDINATE SYSTEM CONVERSION

1. Function Overview

Multiple-machining models have a function to convert the program commands designated in the

Cartesian coordinate system into X and C-axis data in the polar coordinate system on-line.

This function simplifies programming when a hole on the end face of a workpiece is not specified by

the angle but by the vertical distance from a radius vector.

LE33013R0301200010001

[Programming format]

• Start of coordinate system conversion

G137 C__ __ __

• Cancelation of coordinate system conversion

G136

[Details]

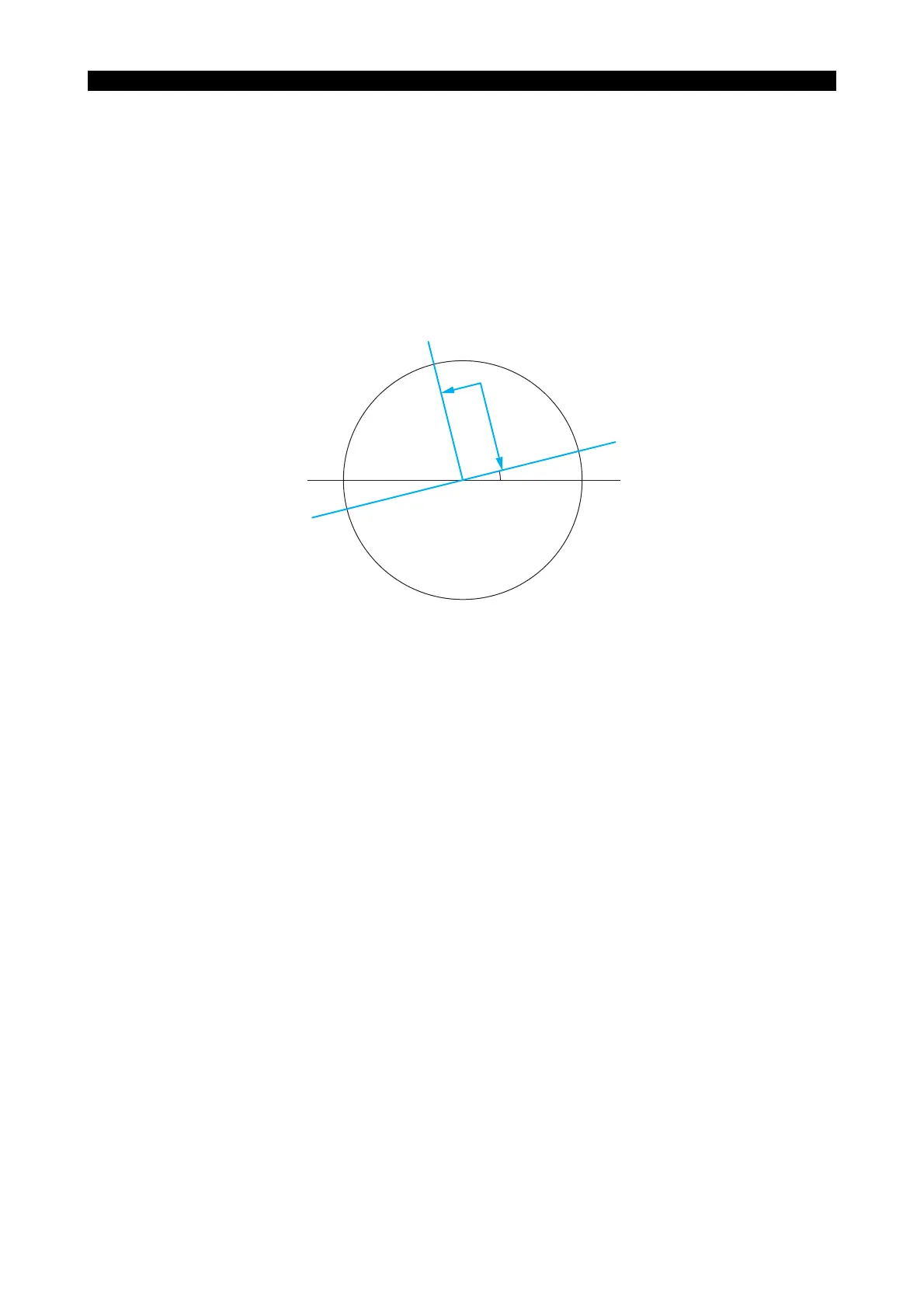

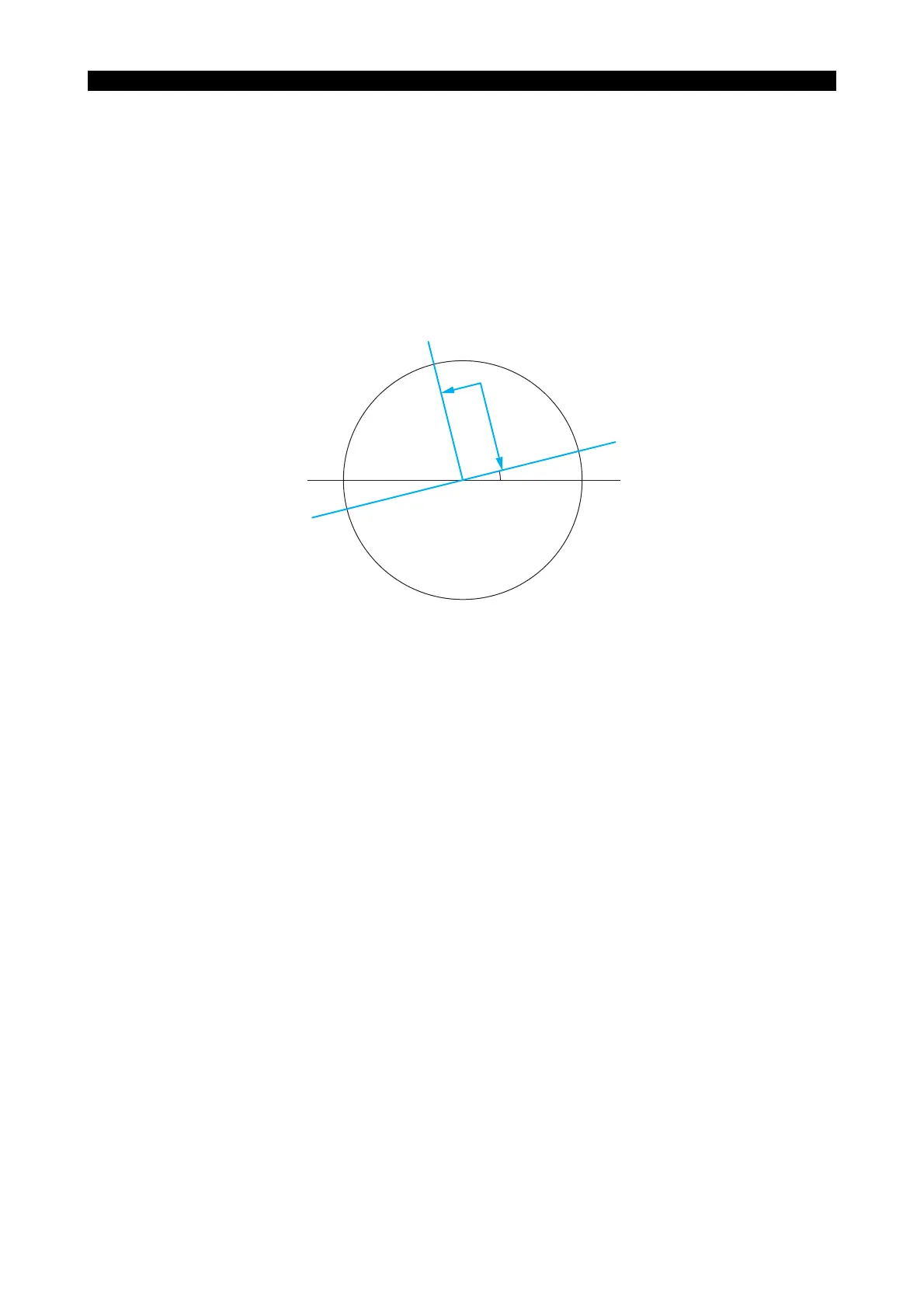

• When G137 is designated, a Cartesian coordinate system is set. In this coordinate system, the

Z-axis is taken as the zero point, and the straight line in the direction of angle C designated in

the G137 block is taken as the positive coordinate axis of X.

After the designation, commands are given using the X and Y words instead of using the X and

C words. Values for the X and Y words are given as radius values. Prefix X and Y words of the

specified Cartesian coordinate system with a plus (+) or minus (-) sign.

• After the completion of positioning using X and Y words in the G137 mode, proceed to

machining. As the machining mode, select a compound fixed cycle or G01.

Since G00, G01, and G codes designating compound fixed cycles are canceled by G137,

designate them in the next block.

• If the coordinate conversion command is designated while the X- or Z- axis is at its travel end

limit position, an alarm occurs.

C : Angle of C-axis that defines the orthogonal coordinate system (θ)

First quadrant : X > 0 Y > 0 Second quadrant : X < 0 Y > 0

Third quadrant : X < 0 Y < 0 Fourth quadrant : X > 0 Y < 0

+Y

+X

Z

C = 0°

θ

Loading...

Loading...