5238-E P-162

SECTION 7 FIXED CYCLES

8-22. Program Examples

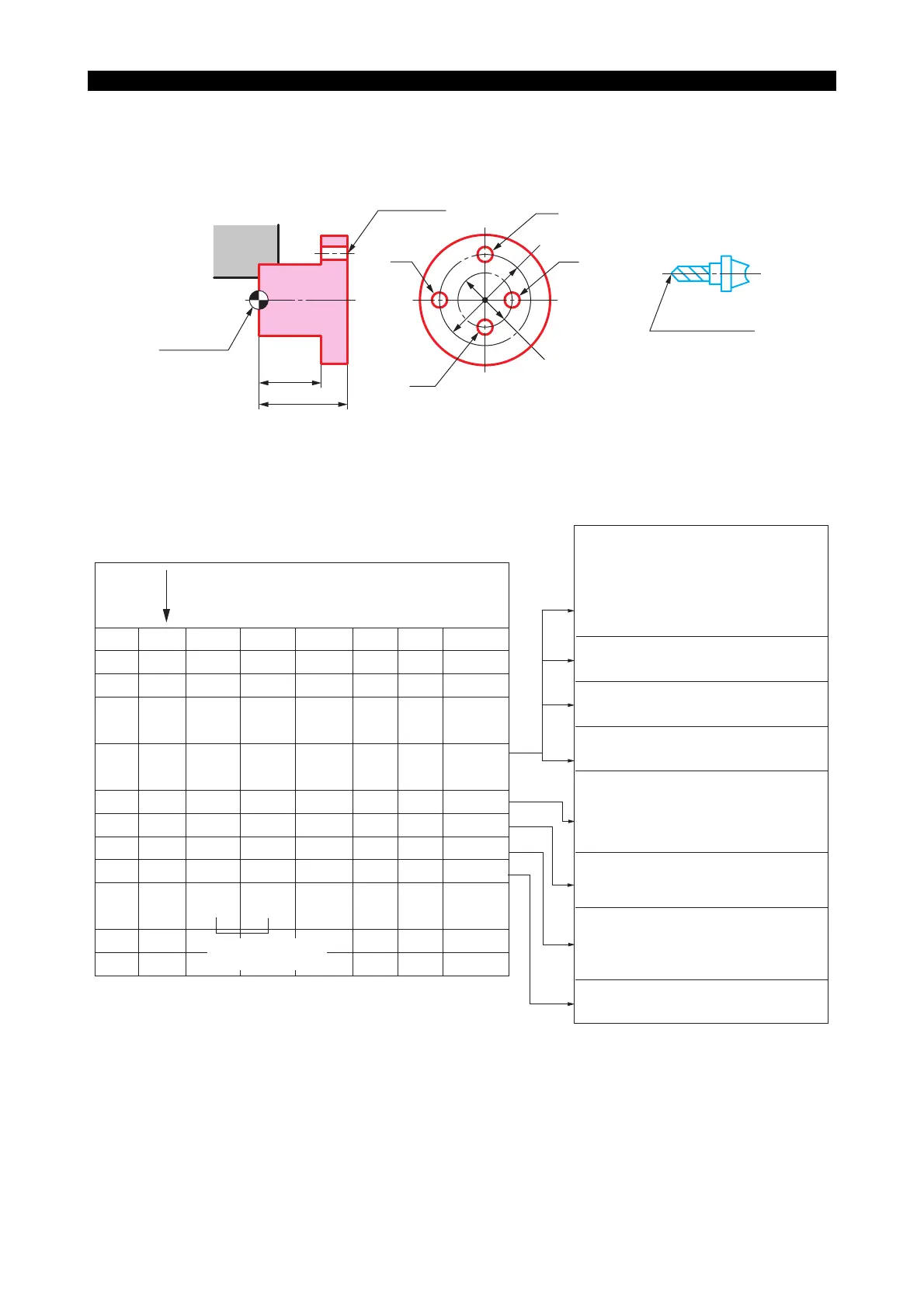

LE33013R0300900520001

When drilling the four 15 mm dia. holes shown above, program as below using G181 for the drilling

cycle.

LE33013R0300900520002

Command point

Example 1:

ø15 hole

Tool No. : T0101

Program

zero

Tool : ø15 drill

80

100

A

B

C

D

C270

C180 C0

C90

60φ

120φ

SB = 400 min

-1

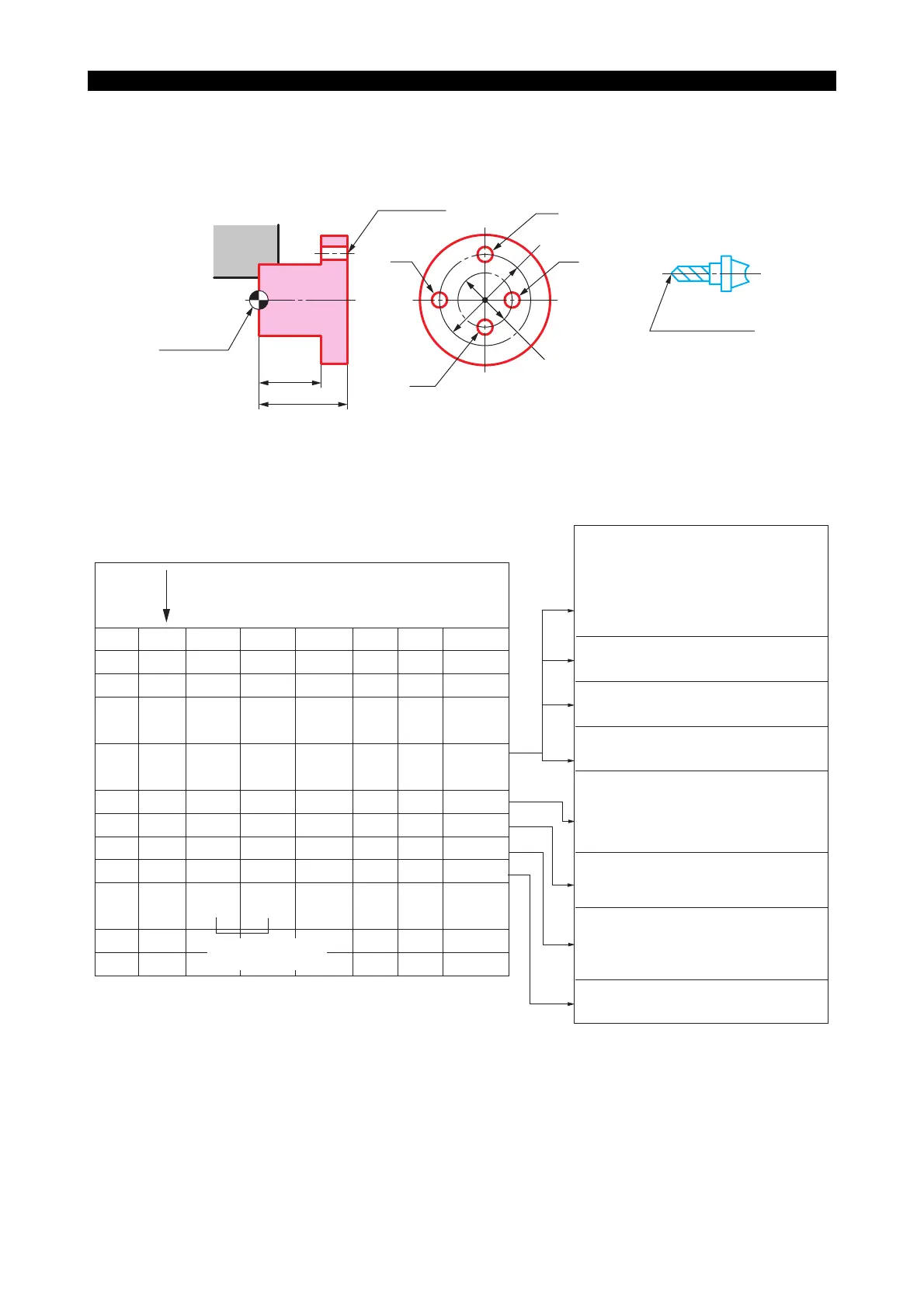

N099

N100

N101

N102

N103

N104

N105

N106

N107

N108

N109

N110

G00

G094

G181

G180

G00

G95

X1000

X200

X60

X120

X60

X1000

X1000

Z150

Z75

(R-27)

Z1000

C0

C90

C180

C270

K48 F40

M05

M110

M15

T0101

SB=400

M146

M12

M109

M02

Continued from turning operation program

Both X and Z axes

are programmed.

The spindle (C-axis) indexes to the 0°

position. After the drill is positioned at

X60 at the rapid feedrate, it starts

rotating in the leftward direction at

400 min

-1

.

The drill is positioned at Z102 at the

rapid feedrate.

The drill is fed to Z75 at 40 mm/min,

thereby drilling hole A.

The drill is returned to Z102 at the

rapid feedrate.

The spindle indexes to the 90° position.

After the drill is positioned at X120 at

the rapid feedrate, it drills hole B in th

same manner as N103.

After the spindle indexes to the 180°

position, the same drilling cycle is

executed for hole C.

After the spindle indexes to the 270°

position, the drill is positioned at X60

and then the same drilling cycle is

executed for hole D.

G180 cancels the fixed cycle mode.

Loading...

Loading...