5238-E P-64

SECTION 6 OFFSET FUNCTION

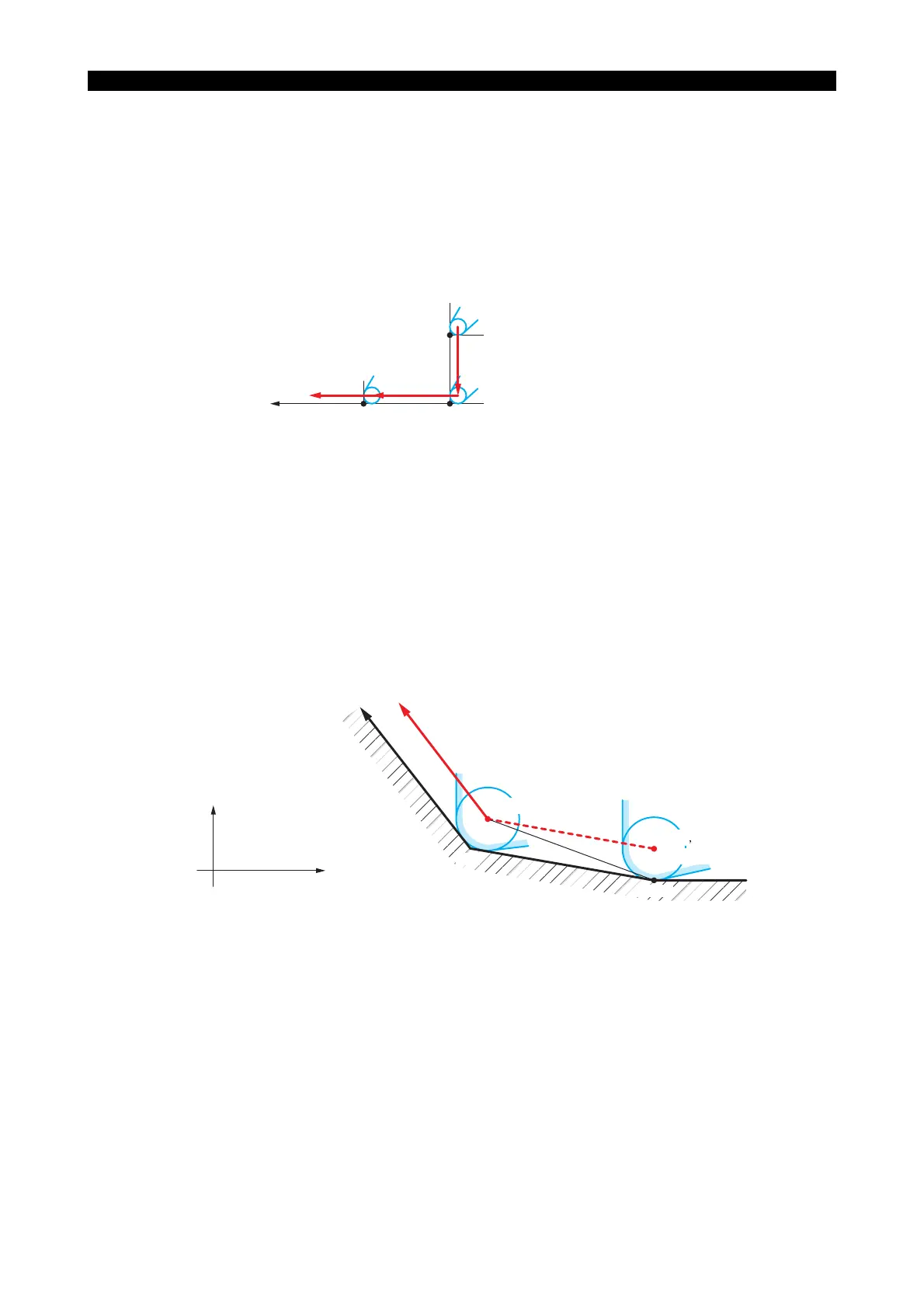

• Example of an ideal program for entry into the compensation mode:

LE33013R0300800090004

In this program, the G42 block contains only a Z word, and points N2, N3 and N4 are all

positioned on the same straight line.

• Either G00 or G01 must dominate the operation mode when entering into the tool nose radius

compensation mode. Otherwise, an alarm will occur.

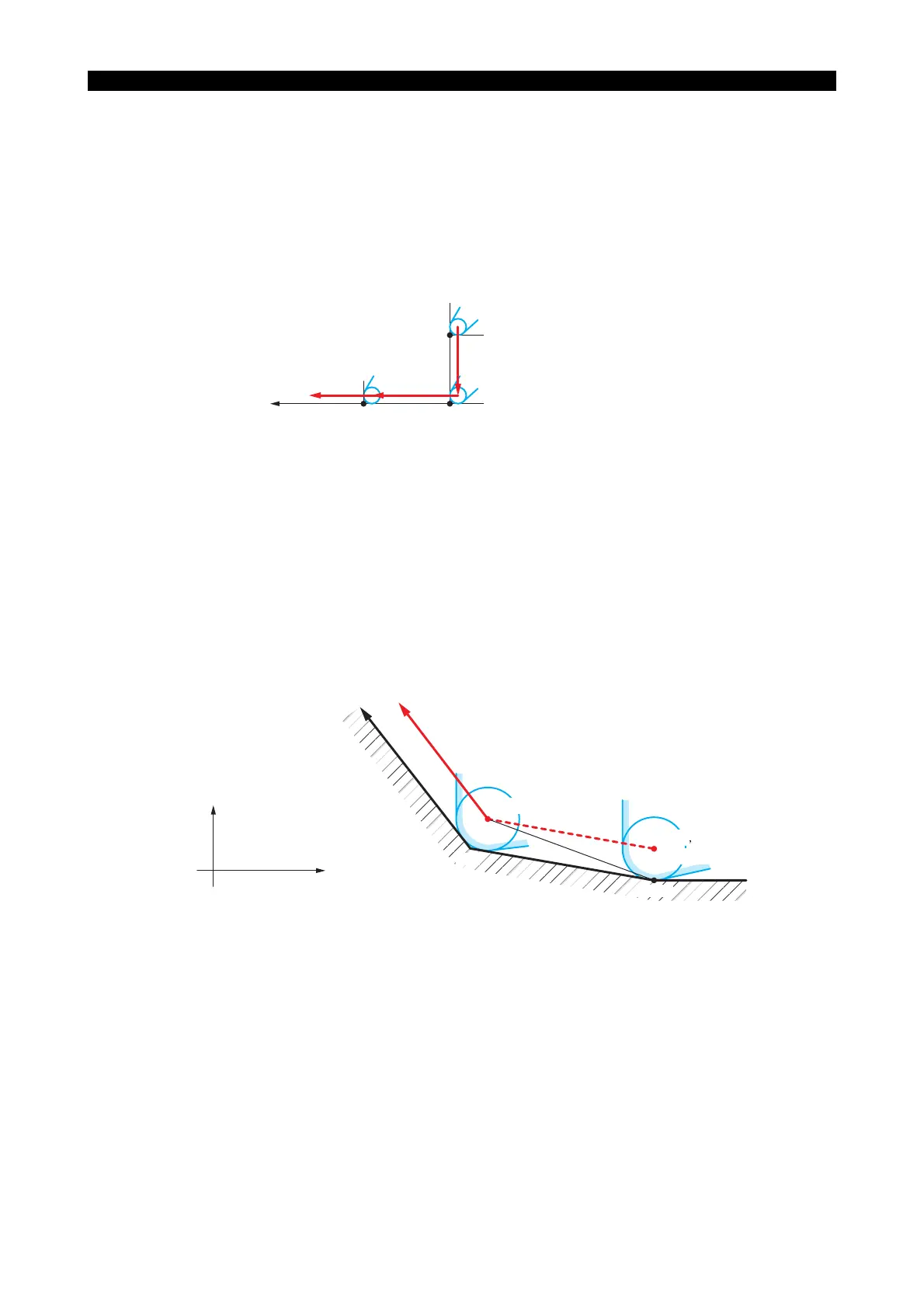

• When neither an X nor Z word is presented at the start up of the tool nose radius compensation

mode, or when the point where the axes are presently located is specified in the start-up block,

positioning is executed so that tool tip circle comes in contact with the segment passing through

the designated coordinates and the coordinates in the next sequence. The tool nose radius

compensation motion is activated from the following sequence.

LE33013R0300800090005

With the program above, the tool tip circle is positioned so that it comes into contact with

segments N2N3 and N3N4. That is, the blocks of commands after N3 sequence are all

executed in the tool nose radius compensation mode.

N1

N2

N3

G00

G42

X100

X80

Z100

Z90

S1000 T010101 M3

F0.2N4 Z50G01

::

N4

N3 N2

N1

X+

Z+

N4

N3

( Z3c, X3c )

( Z1c, X1c )

( Z2c, X2c )

N2,N1

Workpiece

N1

N2

N3

G00

G42

X100

X60

X100

Z100 F0.2

Z80

S1000 T010101 M3

N4 Z50

Loading...

Loading...