CHAPTER 8 TROUBLESHOOTING

E5CK

8–2

8.1 Initial Checks

If trouble occurs, first of all check the following:

(1) Power supply

Make sure that the power supply is ON. Also, make sure that the powĆ

er supply is within the rated voltage range.

(2) Input type jumper

Make sure that the input type jumper is set to the correct input type.

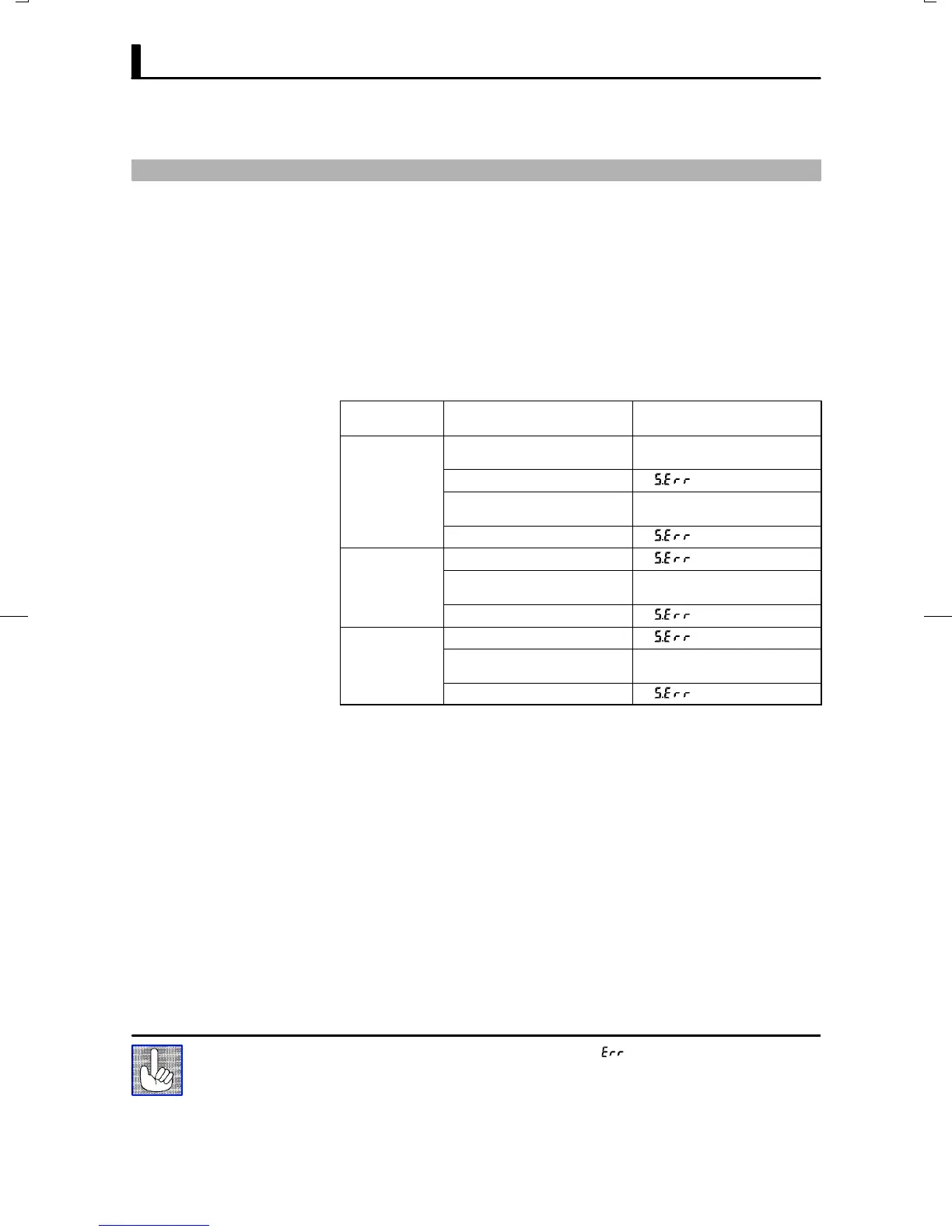

The table below describes the operations when the jumper is not set

matched to the type of sensor connected to the input terminal.

Jumper

Setting

Parameter Operation

TC/PT

Current (0 to 20 mA) Operation is fixed at scaling lower

limit value.

Current (4 to 20 mA)

Voltage (0 to 10 V, 0 to 5 V) Operation is fixed at scaling lower

limit value.

Voltage (1 to 5 V)

I

Temperature input

Voltage (0 10 V, 0 to 5 V) Operation is fixed at scaling lower

limit value.

Voltage (1 to 5 V)

V

Temperature input

Current (0 to 20 mA) Operation is fixed at scaling lower

limit value.

Current (4 to 20 mA)

(3) Wiring

Make sure that all cables are properly connected.

(4) Communications conditions

When communicating via the RSĆ232C, RSĆ422 or RSĆ485 interfaces,

make sure that the baud rate and other communications condition

settings on the host computer and E5AKĆT controller are matching,

and are within the permissible ranges.

If there appears to be nothing wrong after checking the E5CKĆT controller,

and the same phenomenon continues, check the controller in more detail,

for example, on the error display.

If an error occurs during motor calibration, " is displayed on the No.2 display.

The following causes of errors are possible:

Ă• Control motor or potentiometer malfunction

Ă• Incorrect control motor or potentiometer wiring

Ă• Potentiometer is not connected

About Errors That

Occur During

Motor Calibration

Loading...

Loading...