Page 3

FOREWORD

This

workshop

manual has been

compiled

for

use in

conjunction

with

normal

workshop

practice.

Mention

of

certain

accepted

practices

therefore, has been purposely

omitted

in

order

to

avoid

repetition.

Reference to renewing

joints

and cleaning off

joint

faces has to a

great

extent

been

omitted

from

the text, it being understood

that

this will be

carried

out

where

applicable.

Similarly,

it

is

understood

that

in reassembly and inspection, all parts are

to

be

thoroughly

cleaned

and where present,

burrs

and scale are to be removed.

It

follows

that any open ports

of

high

precision components, e.g., fuel

injection

equipment,

ex-

posed

by

dismantling, will be

blanked

off until reassembled, to prevent the

ingress

of

foreign

matter.

: When setscrews

or

studs are fitted into holes which are

tapped

through

into

the

inside

of

: the engine, a

suitable

sealant must be used on the threads.

Throughout

this manual, whenever the

"left"

or

"right"

hand side

of

the

engine

is

referred

to, it is

that

side

of

the

engine

as viewed from the flywheel end.

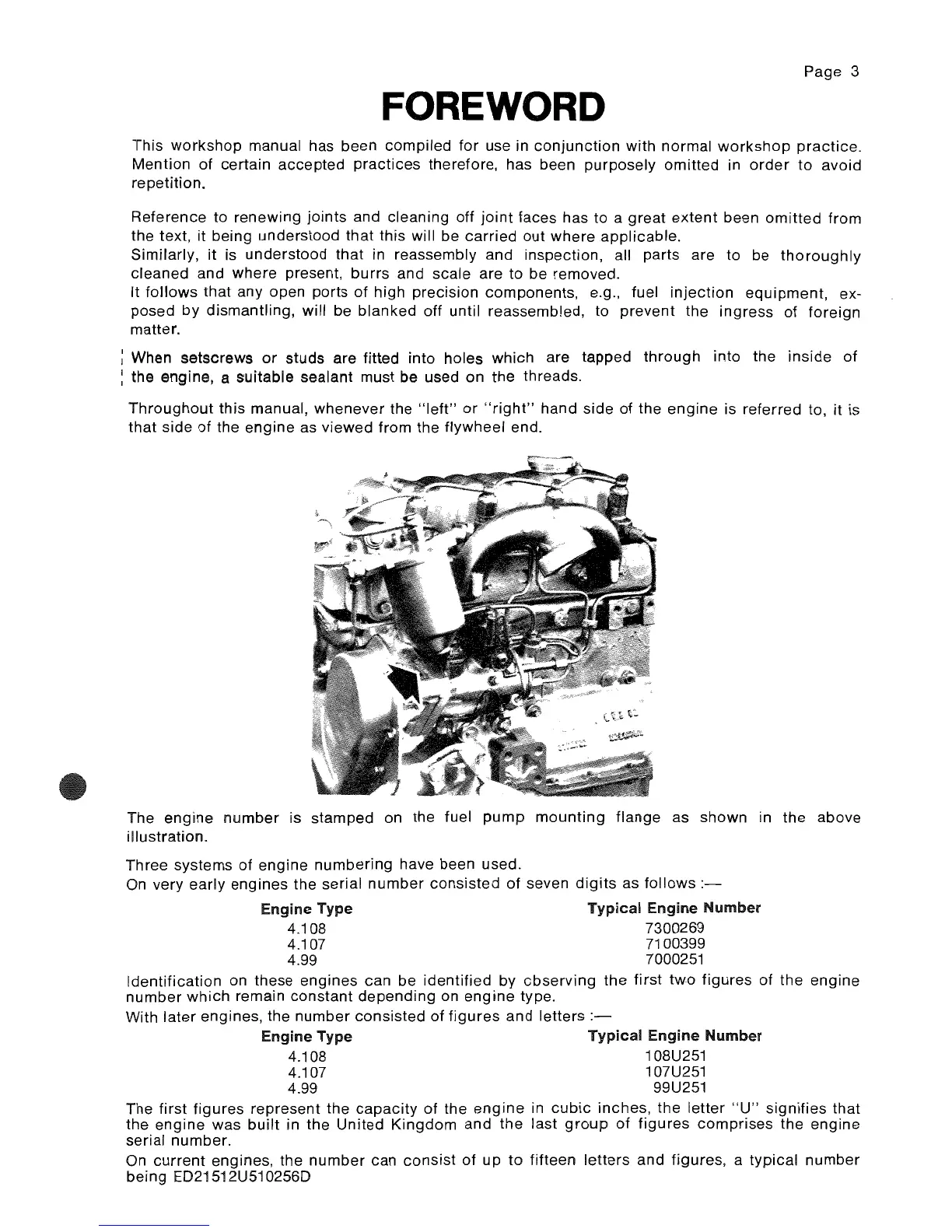

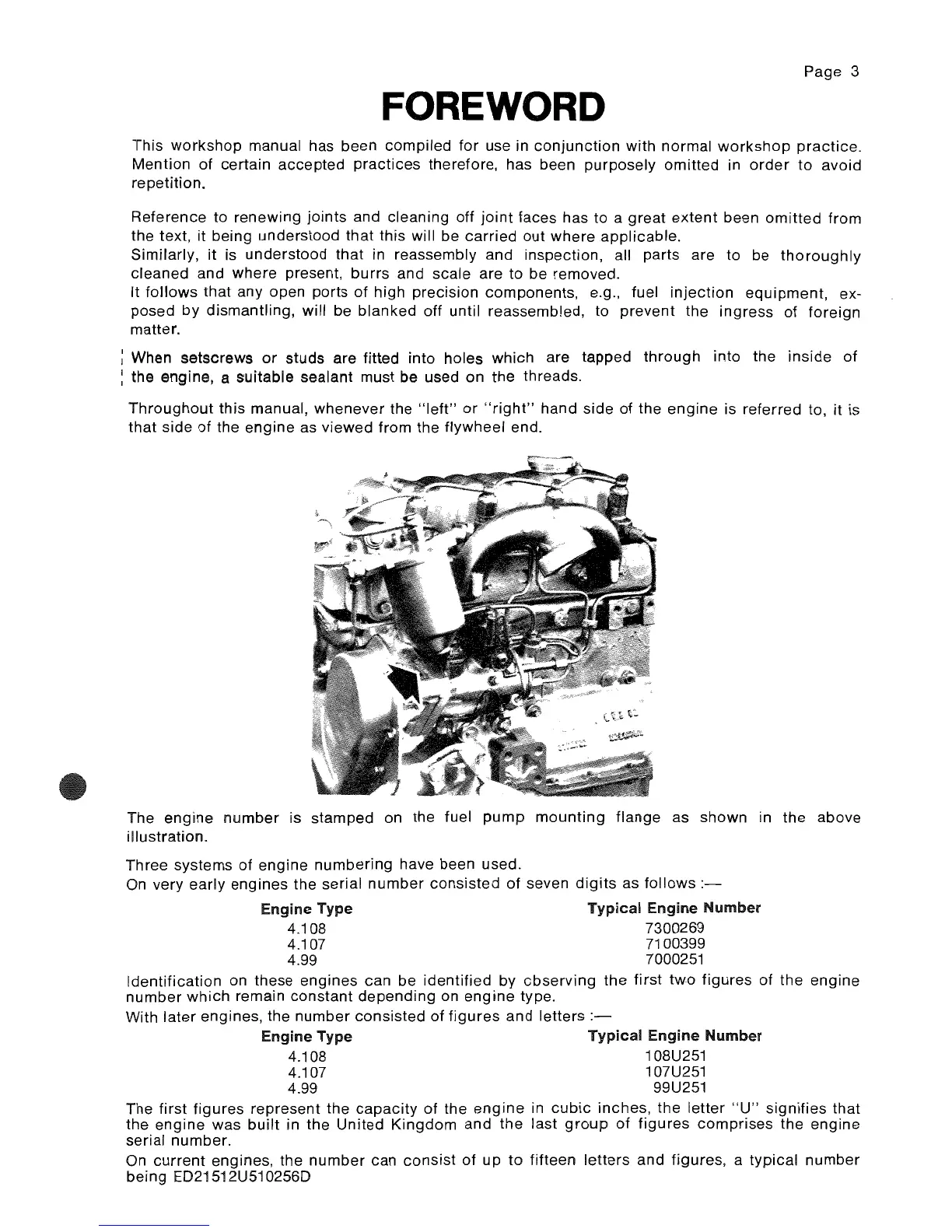

The

engine

number

is stamped on the fuel

pump

mounting

flange

as shown in

the

above

illustration.

Three systems

of

engine

numbering

have been used.

On

very early engines the serial

number

consisted

of

seven

digits

as

follows

:-

Engine Type

Typical

Engine

Number

4.108 7300269

4.107 7100399

4.99 7000251

Identification

on these

engines

can be

identified

by

cbserving

the

first

two

figures

of

the

engine

number

which

remain

constant

depending

on

engine

type.

With

later

engines, the

number

consisted

of

figures

and

letters

Engine Type

Typical

Engine

Number

4.108 108U251

4.107 107U251

4.99 99U251

The first

figures

represent the

capacity

of

the

engine

in

cubic

inches,

the

letter

"U"

signifies

that

the

engine

was

built

in the

United

Kingdom

and

the

last

group

of

figures

comprises

the engine

serial number.

On

current

engines, the

number

can

consist

of

up

to

fifteen

letters

and

figures, a typical

number

being ED21512U510256D

Loading...

Loading...