LUBRICATION

SYSTEM-L.6

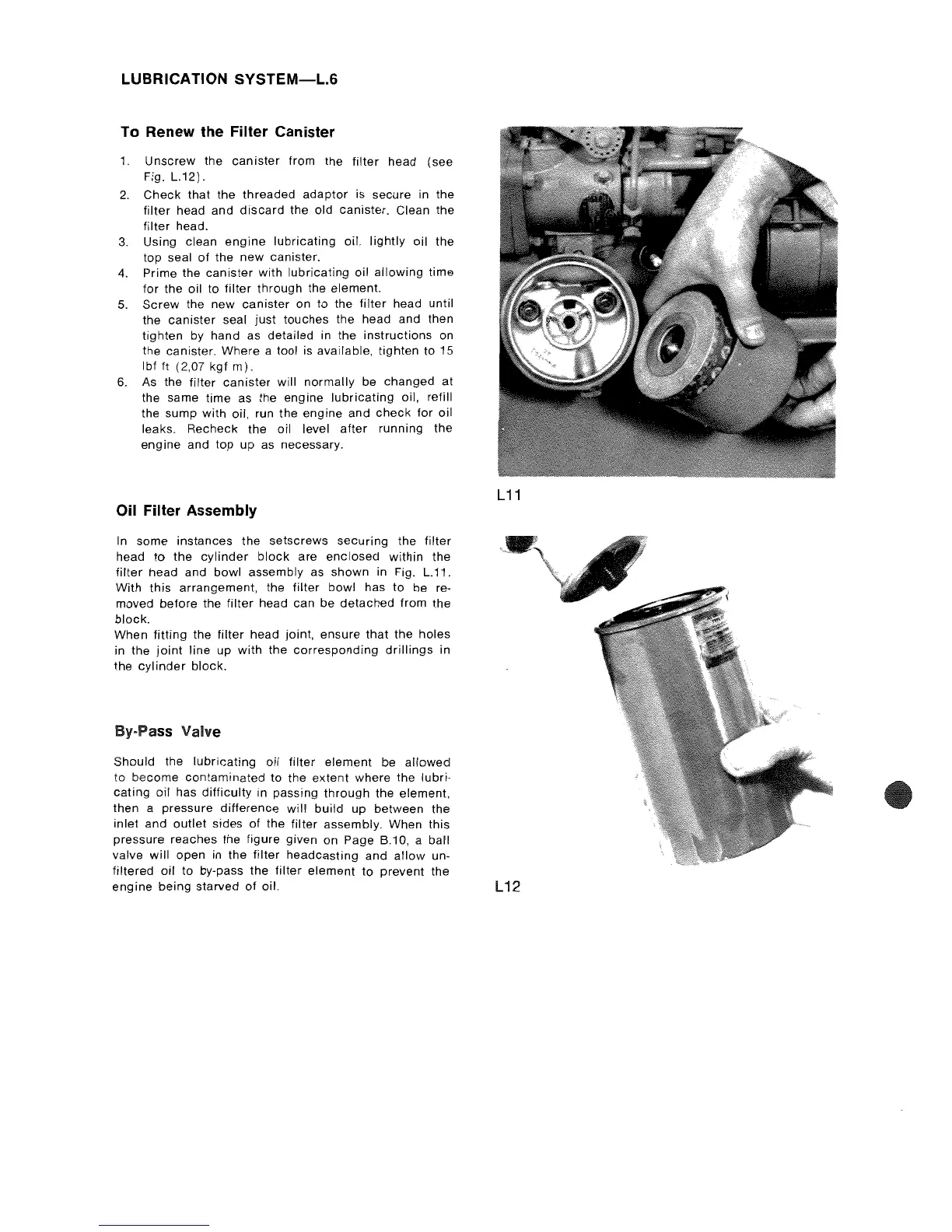

To Renew the Filter Canister

1.

Unscrew

the

canister

from the

filter

head (see

Fig.

L.12).

2.

Check

that the

threaded

adaptor

is secure in the

filter

head and

discard

the

old

canister. Clean the

filter

head.

3.

Using clean

engine

lubricating

oil,

lightly

oil the

top

seal

of

the

new

canister.

4.

Prime the

canister

with

lubricating

oil

allowing

time

for

the oil to

filter

through the element.

5.

Screw

the new

canister

on

to

the

filter

head

until

the canister seal

just

touches the head and then

tighten by hand as detailed in the

instructions

on

the canister. Where a tool

is

available, tighten to 15

Ibf

It

(2,07

kgf

m).

6.

As the

filter

canister

will

normally

be changed

at

the same time as the engine

lubricating

oil, refill

the sump

with

oil, run the engine and

check

for

oil

leaks. Recheck

the

oil level

after

running the

engine and

top

up

as

necessary.

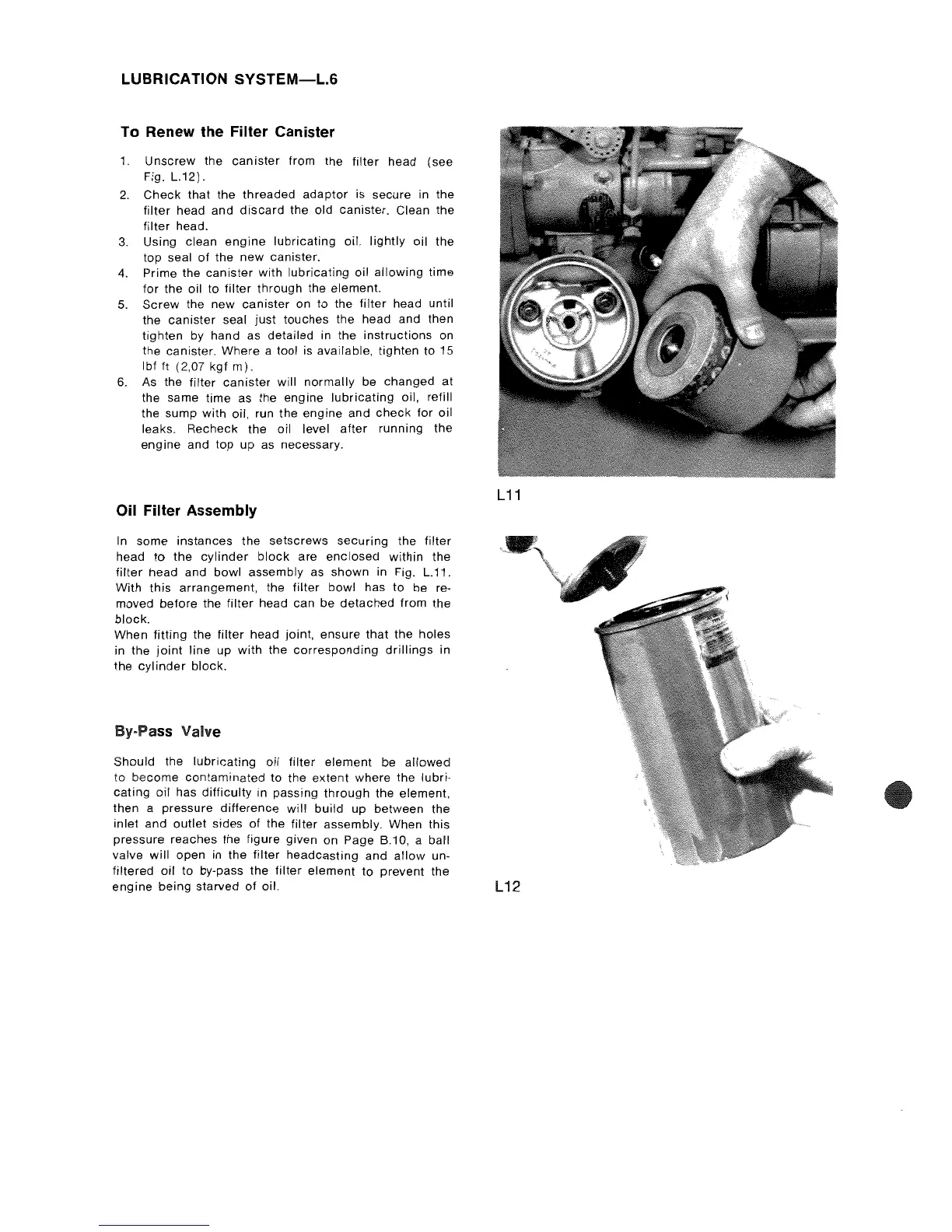

Oil Filter Assembly

In some instances

the

setscrews

securing

the

filter

head

to

the

cylinder

block

are

enclosed

within

the

filter

head and bowl assembly as

shown

in Fig. L.11.

With

this

arrangement, the

filter

bowl

has

to

be re-

moved

before

the

filter

head can be

detached

from

the

block.

When

fitting

the

filter

head joint, ensure

that

the

holes

in the

joint

line

up

with

the

corresponding

drillings

in

the

cylinder

block.

By·Pass Valve

Should the

lubricating

oil filter

element

be

allowed

to become

contaminated

to the

extent

where the lubri-

cating

oil

has

difficulty

in passing

through

the element,

then a pressure

difference

will build

up

between the

inlet

and

outlet

sides

of

the filter assembly. When this

pressure reaches the figure

given on Page B.10, a ball

valve

will

open in the

filter

headcasting

and

allow

un-

filtered

oil to by-pass the

filter

element

to

prevent the

L11

engine

being starved

of

oil.

l12

Loading...

Loading...