SECTION F

Pistons and Connecting Rods

F1

To Remove Pistons and Connecting Rods

1. Remove the

cylinder

head assembly. (Refer to

Page

E.1).

2.

Remove the oil sump. (Refer to Page

L.1

).

NOTE: Any

ridges

or

carbon

deposits

around the

top

of

the

cylinder

bore should be removed

with

a suitable

scraper

before

piston

removal is

attempted.

3.

Rotate

the

crankshaft

until one

pair

of

big ends are

at

bottom

dead

centre, then remove

their

respec-

tive

connecting

rod cap

securing

bolts.

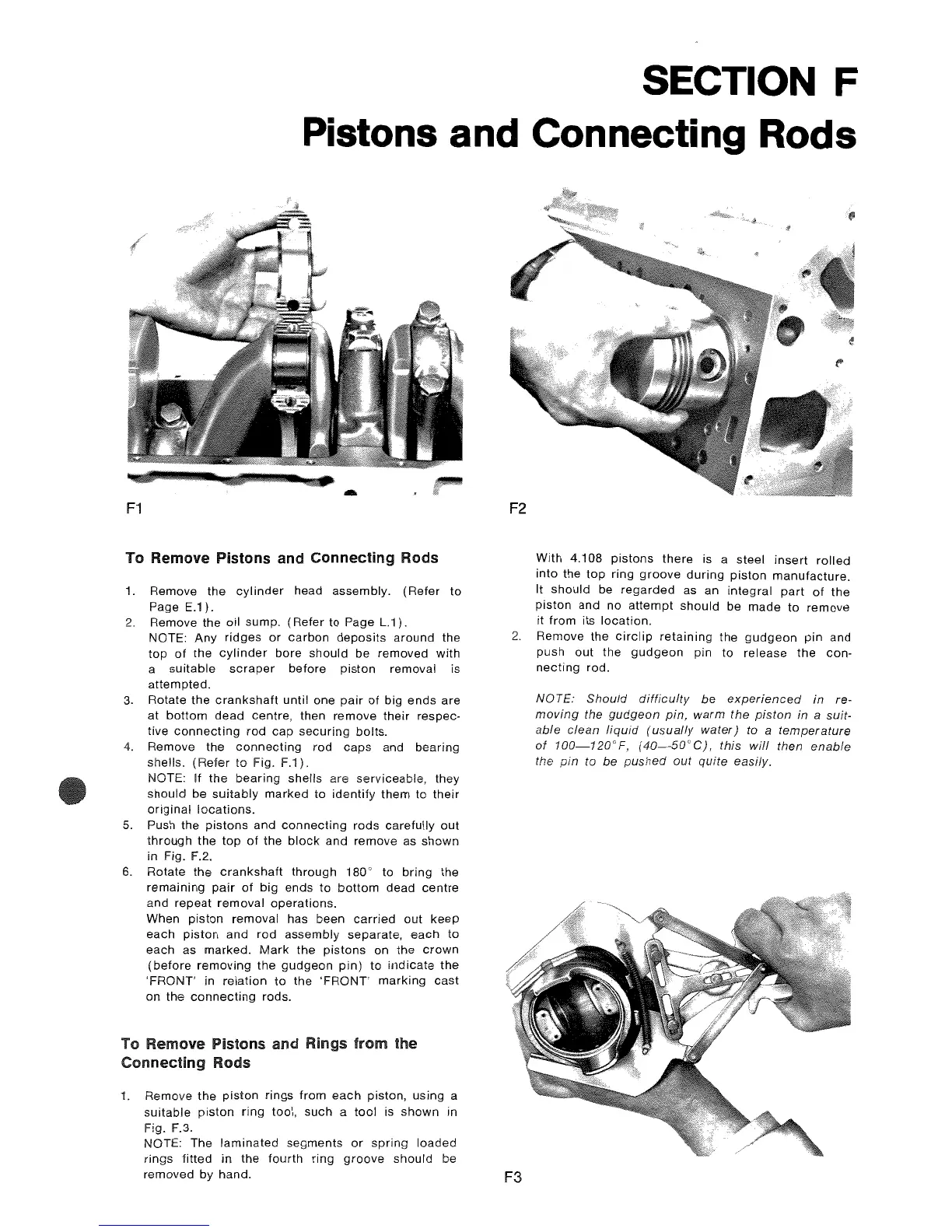

4.

Remove the

connecting

rod

caps

and

bearing

shells.

(Refer

to

Fig. F.1).

NOTE:

If

the

bearing

shells are serviceable, they

should

be

suitably

marked

to

identify

them to

their

original

locations.

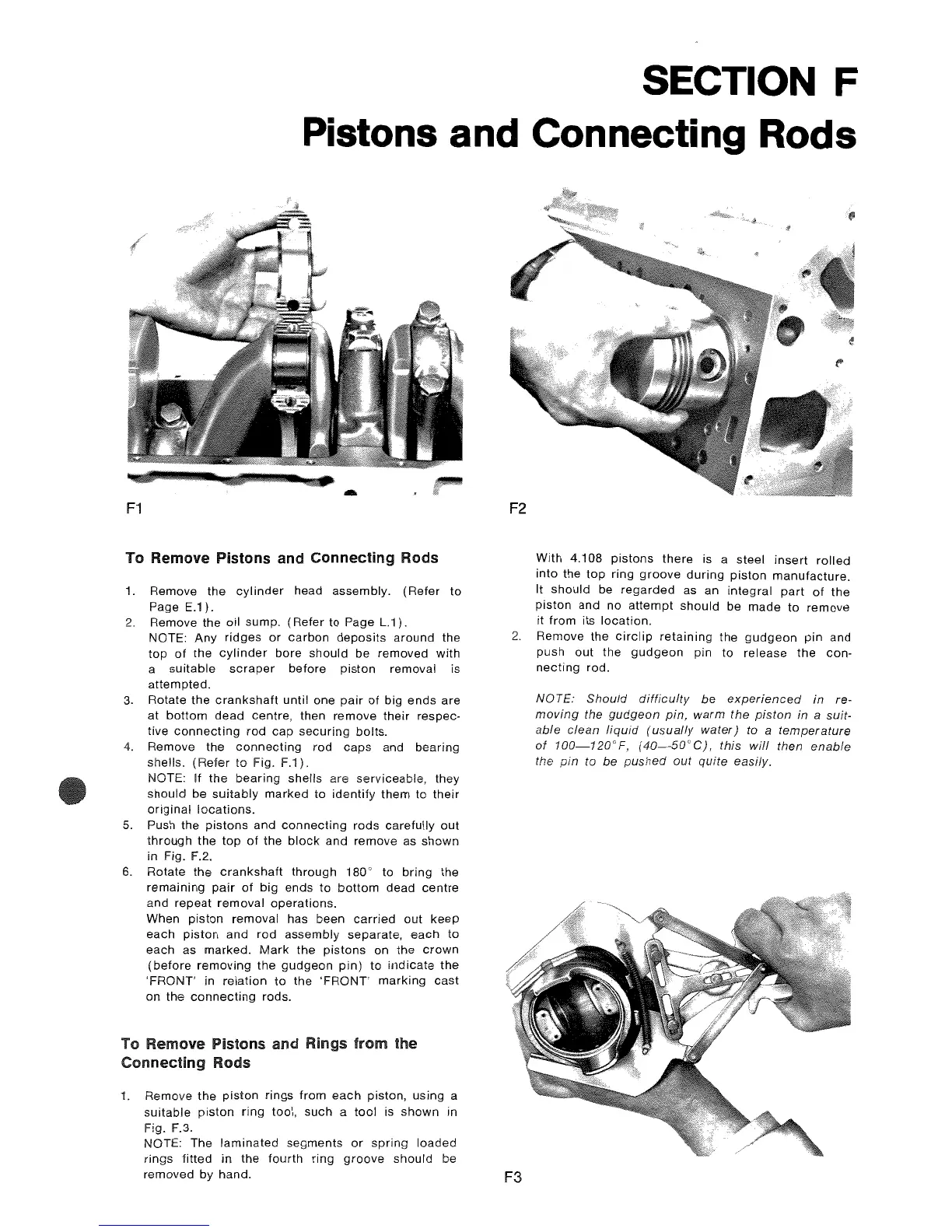

5.

Push the

pistons

and

connecting

rods

carefully

out

through

the top

of

the

block

and remove as

shown

in Fig. F.2.

6.

Rotate the

crankshaft

through

180 Q

to

bring

the

remaining

pair

of

big ends

to

bottom

dead

centre

and

repeat

removal operations.

When

piston

removal has been

carried

out keep

each

piston

and

rod assembly separate,

each

to

each as marked.

Mark

the

pistons

on the

crown

(before

removing

the

gudgeon

pin)

to

indicate

the

'FRONT' in

relation

to

the 'FRONT'

marking

cast

on the

connecting

rods.

To Remove Pistons and Rings from the

Connecting Rods

1. Remove the

piston

rings from

each

piston, using a

suitable

piston

ring

tool,

such

a

tool

is shown in

Fig. F.3.

NOTE: The

laminated

segments

or

spring

loaded

rings fitted in the fourth ring

groove

should

be

F2

With 4.108

pistons

there

is a steel

insert

rolled

into

the

top

ring

groove

during

piston

manufacture.

It

should

be

regarded

as an integral

part

of

the

piston

and

no

attempt

should

be

made

to

remove

it from its

location.

2.

Remove the

circlip

retaining

the

gudgeon

pin

and

push out the

gudgeon

pin to release

the

con-

necting

rod.

NOTE:

Should

difficulty

be

experienced

in

re-

moving

the

gudgeon

pin,

warm

the

piston

in a

suit-

able

clean

liquid

(usually

water)

to a

temperature

of

100-120°F,

(40-50°C),

this

will

then

enable

the

pin

to

be

pushed

out

quite

easily.

removed by hand. F3

Loading...

Loading...