SECTION J

Timing Case and Drive

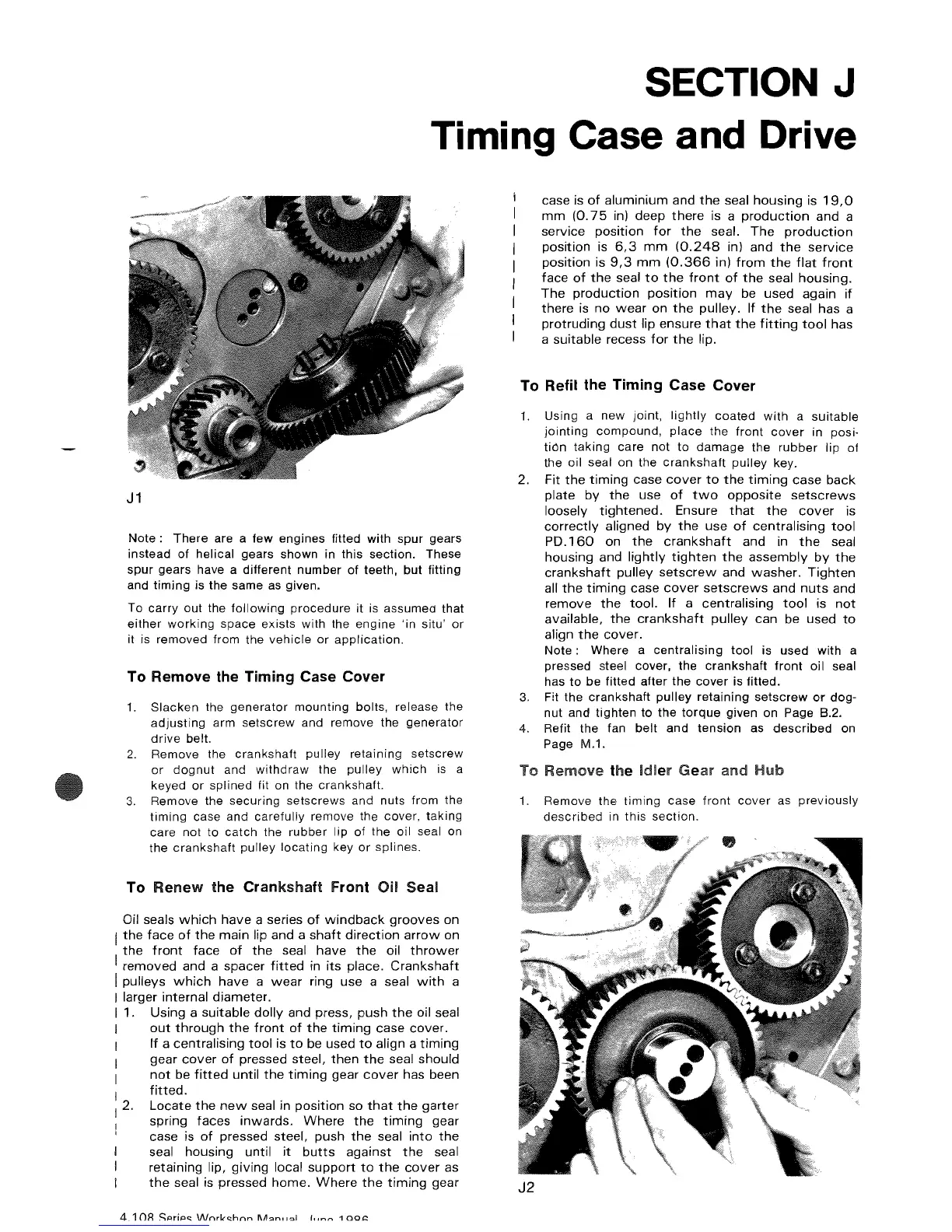

J1

Note:

There are a few engines fitted with spur gears

instead of helical gears shown in this section. These

spur gears have a different number of teeth, but fitting

and timing is the same

as

given.

To carry out the following procedure it is assumed that

either working space exists with the engine 'in situ' or

it is removed from the vehicle or application.

To Remove the Timing Case Covel'

1.

Slacken the generator mounting bolts, release the

adjusting arm setscrew and remove the generator

drive belt.

2.

Remove the crankshaft pulley retaining setscrew

or

dognut and withdraw the pulley which

is

a

keyed

or

splined fit

on

the crankshaft.

3.

Remove the securing setscrews and nuts from the

timing case and carefully remove the cover, taking

care not to catch the rubber lip of the oil seal on

the crankshaft pulley locating key or splines.

To Renew the Crankshaft

front

Oil Seal

Oil seals

which

have

a series

of

windback

grooves

on

I

the

face

of

the

main

and a

shaft

direction

arrow

on

the

front

face

of

the

seal

have

the

oil

thrower

I

removed

and a

spacer

fitted

in

its

place.

Crankshaft

I pulleys

which

have

a

wear

ring use a seal

with

a

I larger

internal

diameter.

I 1. Using a

suitable

dolly

and press,

push

the

oil seal

out

through

the

front

of

the

timing

case

cover.

If

a

centralising

tool

is

to

be used

to

align a

timing

gear

cover

of

pressed steel,

then

the

seal

should

not

be

fitted

until

the

timing

gear

cover

has been

I

fitted.

I 2.

Locate

the

new

seal in

position

so

that

the

garter

spring

faces

inwards.

Where

the

timing

gear

case is

of

pressed steel, push

the

seal

into

the

seal

housing

until

it

butts

against

the

seal

retaining lip,

giving

local

support

to

the

cover

as

case is

of

aluminium

and

the

seal

housing

is

19,0

mm

(0.75

in) deep

there

is a

production

and a

service

position

for

the

seal.

The

production

position

is

6,3

mm

(0.248

in) and

the

service

position

is

9,3

mm

(0.366

in)

from

the

flat

front

face

of

the

seal

to

the

front

of

the

seal

housing.

The

production

position

may

be

used

again

if

there

is

no

wear

on

the

pulley.

If

the

seal has a

protruding

dust

lip

ensure

that

the

fitting

tool

has

a

suitable

recess

for

the

lip.

To Refit the

Timing

Case Cover

1. Using a new joint, lightly coated with a suitable

jointing compound, place the front

cover

in posi-

tion taking care not to damage the rubber lip of

the oil seal on the crankshaft pulley key.

2. Fit

the

timing

case

cover

to

the

timing

case

back

plate

by

the

use

of

two

opposite

setscrews

loosely

tightened.

Ensure

that

the

cover

is

correctly

aligned

by

the

use

of

centralising

tool

PD.160

on

the

crankshaft

and in

the

seal

housing

and

lightly

tighten

the

assembly

by

the

crankshaft

pulley

setscrew

and

washer.

Tighten

all

the

timing

case

cover

setscrews

and

nuts

and

remove

the

tool.

If

a

centralising

tool

is

not

available,

the

crankshaft

pulley

can

be used

to

align

the

cover.

Note:

Where a centralising tool is used with a

pressed steel cover, the crankshaft front oil seal

has to be fitted after the cover is fitted.

3.

Fit the crankshaft pulley retaining setscrew

or

dog-

nut and

lighten

to the torque given on Page B.2.

4. Refit the fan belt and tension as described on

Page M.1.

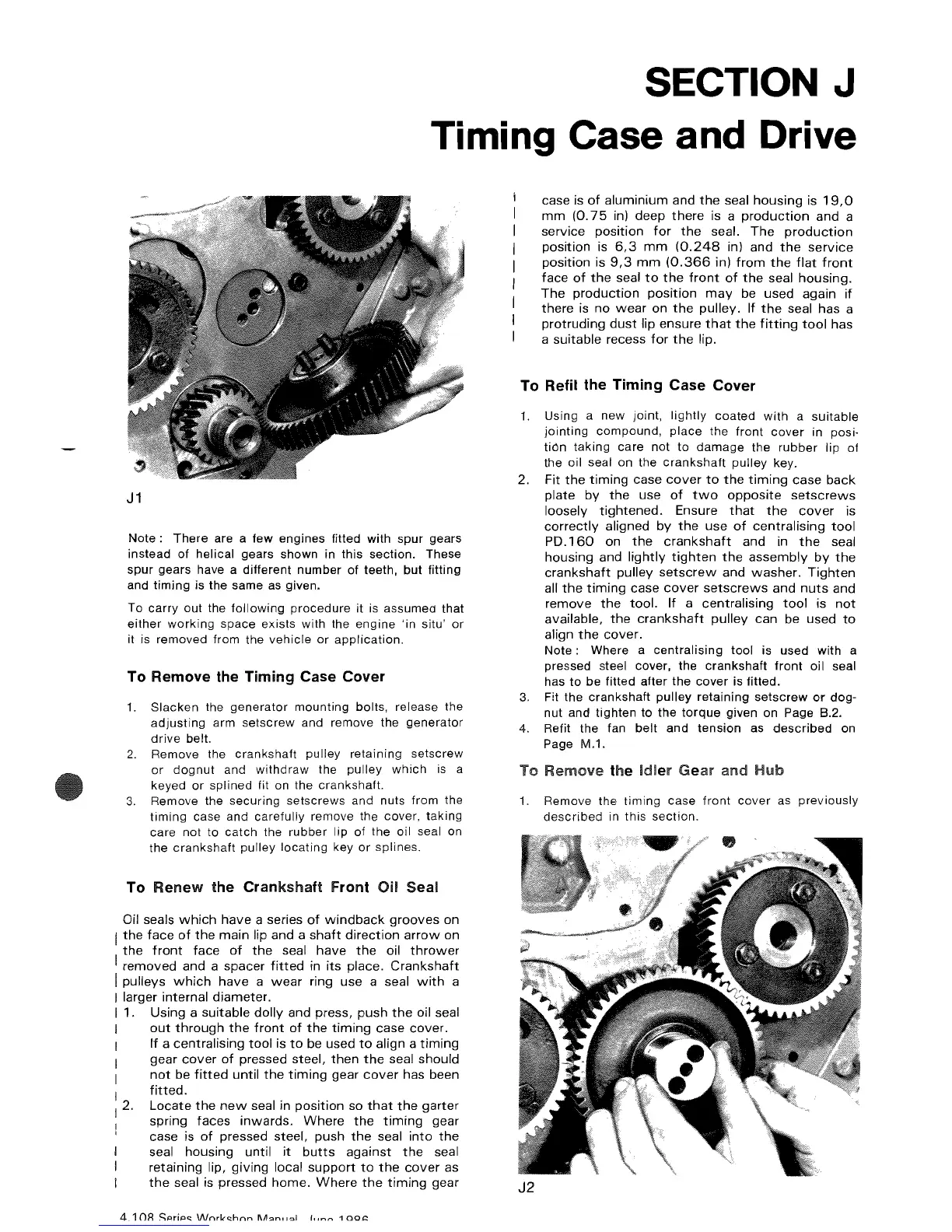

To Remove the

Idler

Gear and Hub

1.

Remove the timing case front cover

as

previously

described in this section.

the

seal is pressed

home.

Where

the

timing

gear

J2

Loading...

Loading...