The

gaps

of

the remaining rings should be stag-

gered

alternately

along the gudgeon pin axis.

Liberally

lubricate

the rings in

their

grooves and

see

that

they can move freely

in

their

locations,

this does

not

apply

to

the laminated type in the

fourth groove,

which

if

correctly

fitted should not

move

freely

due to the outward pressure

of

the top

and bottom segments on the ring

groove

walls.

When all the

rings

have been fitted, they

should

be shown in Fig. F.9.

Always

ensure

that

internally stepped

or

taper

faced

rings are

correctly

fitted. They are

marked

TOP

or

BTM

(bottom)

to

ensure

correct

replacement.

The top

compression

and

slotted

oil

control

rings may

be fitted

either

way up.

Spring

loaded

Scraper Ring

When fitting the

chrome

plated spring loaded

scraper

ring. (see Fig.

F.1

0).

the

following

procedure

should

be

adopted:-

1. Fit internal

expander

(1).

2.

Fit

two

rail

rings

(2)

at the bottom of the groove.

3.

Fit

spiral ring

(3).

4.

Fit

two

top

rail rings

(2).

When fitting rail rings, the gaps should be staggered.

To Fit Piston and Connecting Rod Assemblies

Before fitting the piston and

connecting

rod assemblies

to

their

respective

cylinder

bores,

thoroughly

clean

and liberally

coat

each bore

with

clean

engine

oil.

1. Turn the

engine

until the

crankpins

of

numbers

1 and 4

cylinders

are

at

the bottom dead centre.

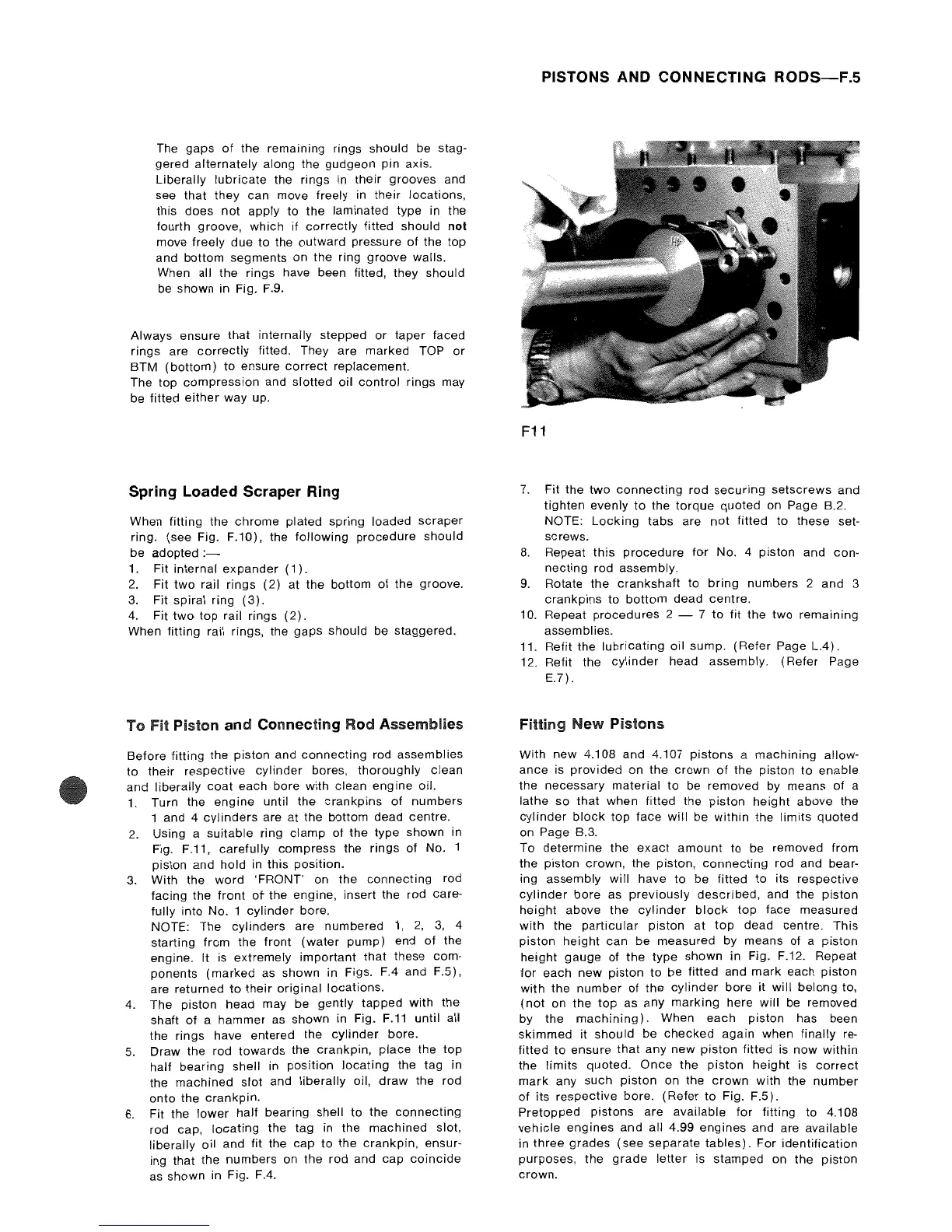

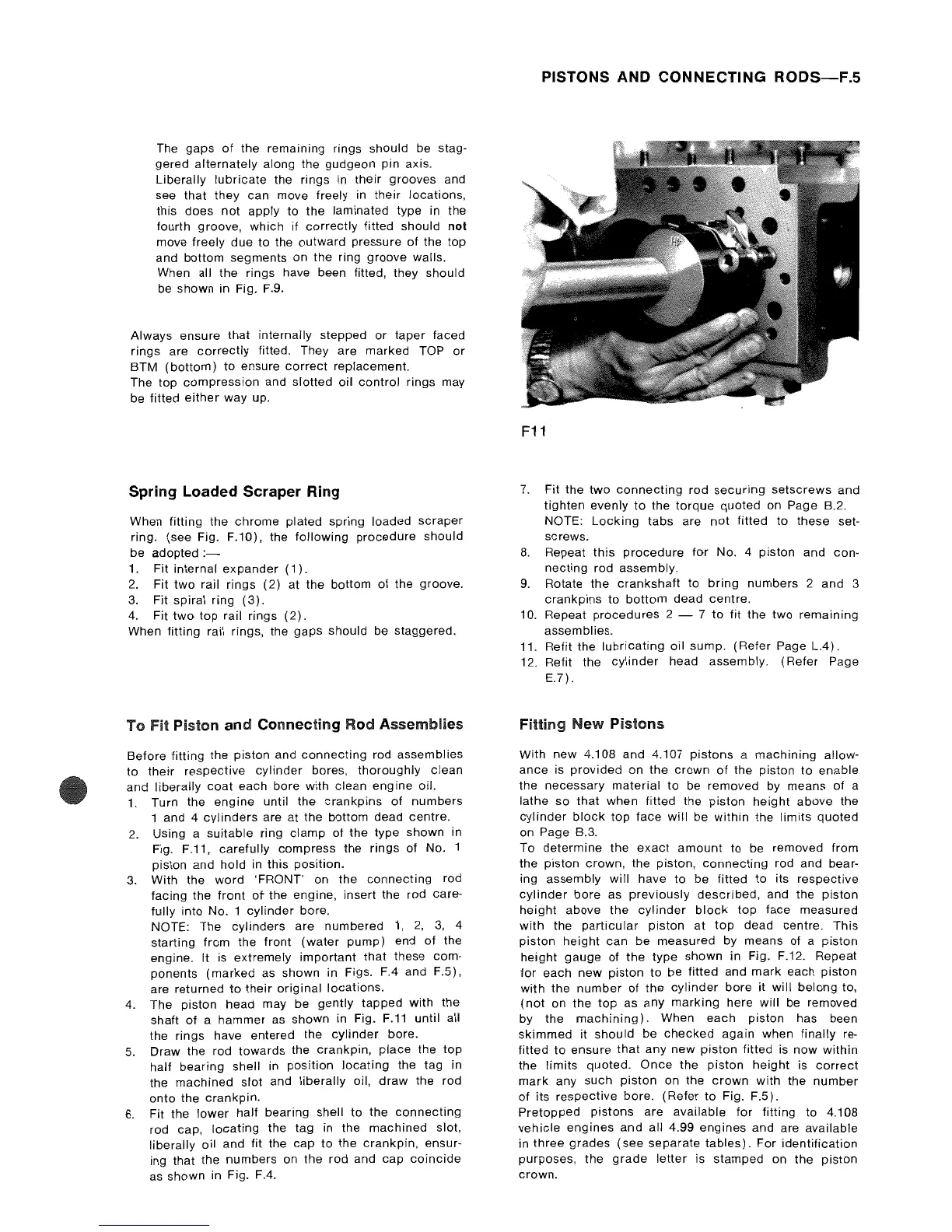

2.

Using a

suitable

ring

clamp

of

the type

shown

in

Fig. F.11,

carefully

compress

the

rings

of

No. 1

piston and

hold

in this position.

3.

With the

word

'FRONT' on the

connecting

rod

facing

the

front

ot

the engine, insert the rod care-

fully into

No.1

cylinder

bore.

NOTE: The

cylinders

are numbered

1,

2,

3,

4

starting from the

front

(water

pump)

end

of

the

engine. It is extremely

important

that

these com-

ponents

(marked

as

shown

in Figs. F.4 and F.5),

are

returned

to

their

original

locations.

4.

The piston head may be

gently

tapped

with

the

shaft

of

a

hammer

as shown in Fig.

F.11

until

all

the rings have entered

the

cylinder

bore.

5.

Draw the rod

towards

the

crankpin,

place the top

half bearing shell in

position

locating

the tag in

the

machined

slot and

liberally

oil,

draw

the rod

onto

the

crankpin.

6.

Fit

the

lower

half

bearing shell

to

the

connecting

rod cap,

locating

the tag in

the

machined

slot,

liberally

oil

and

fit the

cap

to

the

crankpin,

ensur-

ing that the numbers on

the

rod and

cap

coincide

as shown in Fig. F.4.

PISTONS AND CONNECTING

RODS-F.S

F11

7.

Fit the

two

connecting

rod

securing

setscrews

and

tighten

evenly

to

the

torque

quoted

on Page B.2.

NOTE:

Locking

tabs are

not

fitted

to

these

set-

screws.

8.

Repeat

this

procedure

for

No. 4

piston

and

con-

necting

rod assembly.

9.

Rotate

the

crankshaft

to

bring

numbers

2

and

3

crankpins

to

bottom

dead centre.

10. Repeat

procedures

2 - 7

to

fit the

two

remaining

assemblies.

11. Refit the

lubricating

oil sump.

(Refer

Page

L.4).

12. Refit the

cylinder

head assembly.

(Refer

Page

E.7).

Fitting

New

Pistons

With

new 4.108

and

4.107

pistons

a

machining

allow-

ance

is

provided

on the

crown

of

the

piston

to

enable

the

necessary

material

to

be removed by means

of

a

lathe

so

that

when

fitted the

piston

height

above the

cylinder

block

top

face

will

be

within

the

limits

quoted

on Page B.3.

To

determine

the

exact

amount

to be removed from

the

piston

crown, the piston,

connecting

rod and bear-

ing

assembly

will

have

to

be

fitted

to

its respective

cylinder

bore

as

previously

described,

and

the

piston

height

above

the

cylinder

block

top

face measured

with

the

particular

piston

at

top

dead centre. This

piston

height

can be measured by means of a

piston

height

gauge

of

the

type

shown

in Fig. F.12. Repeat

for

each

new

piston

to

be

fitted

and

mark

each piston

with

the

number

of

the

cylinder

bore

it

will

belong

to,

(not

on

the

top

as any

marking

here

will

be removed

by the

machining).

When

each

piston

has been

skimmed

it

should

be

checked

again

when finally re-

fitted

to

ensure

that

any new

piston

fitted is

now

within

the

limits

quoted.

Once

the

piston

height

is

correct

mark

any

such

piston

on the

crown

with

the

number

of

its

respective

bore.

(Refer

to

Fig. F.5).

Pretopped

pistons

are

available

for

fitting to 4.108

vehicle

engines

and

all

4.99

engines

and are available

in

three

grades

(see

separate

tables).

For

identification

purposes,

the

grade

letter

is

stamped

on the

piston

crown.

Loading...

Loading...