CYLINDER BLOCK AND

LlNERS-G.2

G3

suitably

marked

so

that

they may be refitted

to

their

original

parent

bore

and in the same

position

in that

bore, that is,

thrust

side of the

liner

to the

thrust

side

of

the

cylinder

block.

To Renew Cylinder

liners

Remove all

components

from

cylinder

block.

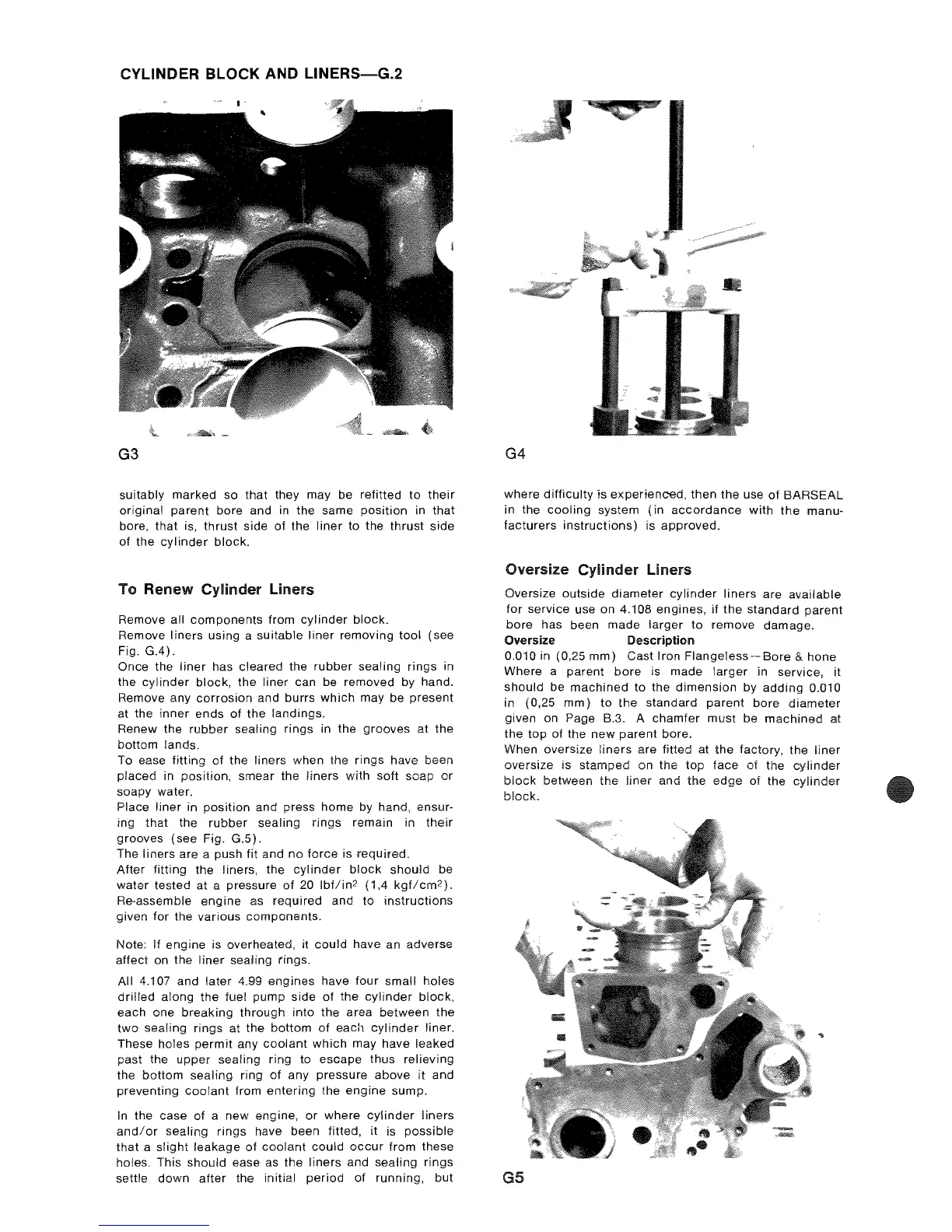

Remove

liners

using a suitable

liner

removing tool (see

Fig.

G.4).

Once the

liner

has cleared the

rubber

sealing rings in

the

cylinder

block,

the

liner

can be removed by hand.

Remove any

corrosion

and burrs

which

may be present

at the

inner

ends

of

the landings.

Renew the

rubber

sealing rings in the

grooves

at

the

bottom lands.

To ease

fitting

of

the liners when the rings have been

placed in position, smear the

liners

with

soft

soap

or

soapy water.

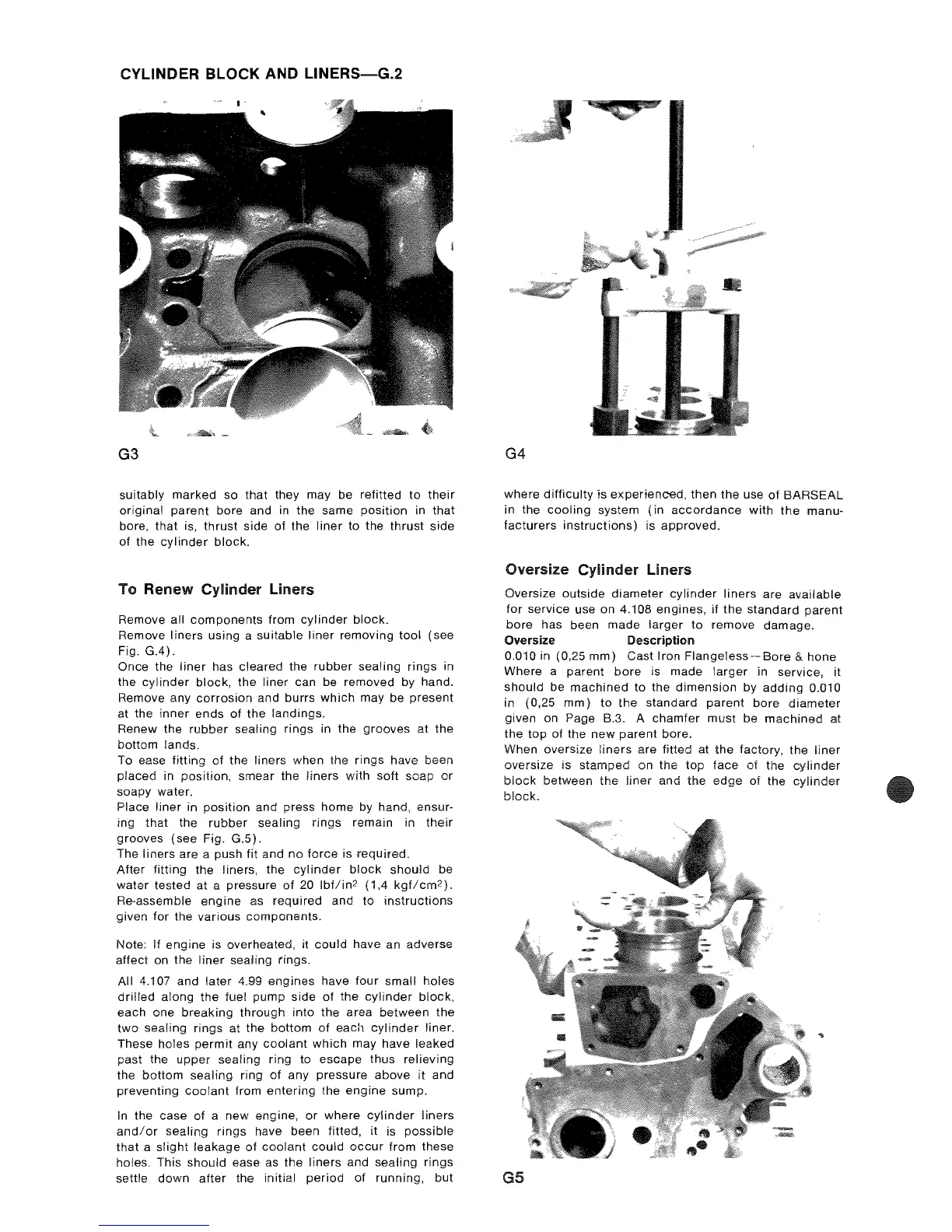

Place

liner

in

position

and

press home by hand, ensur-

ing that the

rubber

sealing

rings

remain in

their

grooves

(see

Fig.

G.5).

The liners are a push fit and

no

force

is required.

After fitting the liners, the

cylinder

block

should

be

water

tested at a pressure

of

20

Ibflin

2

(1,4

kgflcm2).

Re-assemble

engine

as

required

and

to

instructions

given

for

the

various

components.

Note:

If

engine

is overheated, it

could

have an adverse

affect on the

liner

sealing rings.

All 4.107 and

later

4.99

engines

have

four

small holes

drilled

along the fuel pump

side

of

the

cylinder

block,

each one

breaking

through

into

the area between

the

two

sealing

rings

at the

bottom

of

each

cylinder

liner.

These holes

permit

any

coolant

which

may have leaked

past the

upper

sealing ring to escape

thus

relieving

the

botiom

sealing

ring

of

any pressure above it

and

preventing

coolant

from

entering

the

engine

sump.

In

the case

of

a

new

engine,

or

where

cylinder

liners

and/or

sealing rings have been fitted,

it

is

possible

that a

slight

leakage

of

coolant

could

occur

from

these

holes. This

should

ease as

the

liners

and

sealing

rings

G4

where

difficulty

is

experienced,

then

the

use

of

BARSEAL

in the

cooling

system

(in

accordance

with

the

manu-

facturers

instructions)

is

approved.

Oversize Cylinder

liners

Oversize outside

diameter

cylinder

liners

are

available

for

service use on 4.108 engines,

if

the

standard

parent

bore

has been

made

larger

to

remove damage.

Oversize

Description

0.010 in (0,25

mm)

Cast Iron Flangeless

Bore

&

hone

Where a

parent

bore

is

made

larger

in service,

it

should

be

machined

to the

dimension

by

adding

0.010

in (0,25

mm)

to the standard

parent

bore

diameter

given on Page B.3. A chamfer

must

be

machined

at

the

top

of

the

new

parent

bore.

When oversize

liners

are fitted at

the

factory,

the

liner

oversize is

stamped

on the

top

face

of

the

cylinder

block

between

the

liner

and

the

edge

of

the

cylinder

block.

settle

down

after

the

initial

period

of

running,

but

G5

Loading...

Loading...