the valve in

the

outlet

port

fitted in the reverse

position.

3.

Press the valves home with a suitable

piece

of

tubing.

approximately

9/16

in (14,29

mm)

inside

diameter

and

{f

in (19,05

mm)

outside diameter.

4.

Stake the

casting

in six places

(between

the

original

stakings)

round each valve, with a suitable

punch.

NOTE: Valves fitted

to

earlier

lift

pumps were

held in

position

with a retaining plate and

two

screws. On

no

account

should attempts be made

to

stake the valves of this

earlier

type pump.

5.

Place the

rocker

arm retaining pin in the appro-

priate hole in the

lower

casting and push

through

until it

protrudes

slightly inside.

6. Fit one

packing

washer and the

link

into

the

casting

moving the

pin

in slightly

to

retain them.

7. Fit the

rocker

arm and return

spring

and retain by

moving the

pin

in further, ensuring that the

spring

seats

correctly.

8. Fit the

remaining

packing washer, then push

the

rocker

arm retaining pin through the link, washer

and

casting

until

the ends

protrude

equally beyond

the outside

of

the

casting.

9.

Retain by

securing

with the

two

clips.

10. Insert the

new

rubber

sealing washer

followed

by

the steel seating washer and

diaphragm

return

spring.

11. Place the

diaphragm

assembly

over

the

spring

with the pull rod downwards,

locating

the

top

of

the

spring

in

the

diaphragm

protector

washer.

12.

Now

position

the

pull rod

so

that the flat

notched

blade

has one

of

its

thin

edges

facing

the

rocker

arm. Press

downwards

on the

diaphragm

assembly

and

twist

it

through

90" in

either

direction,

this

action

will

engage and retain the pull rod in

the

fork

of

the link.

13. Operate the

rocker

arm

against

the

diaphragm

spring

pressure until the

diaphragm

is level

with

the

body

flange.

14. Place the

cover

assembly in

position

and line

up

the

file

marks

made on the flanges

prior

to

dismantling.

15. Still

holding

the

diaphragm

level

with

the

body

flanges, fit

the

five flange

securing

screws,

tighten

evenly and securely.

To Refit the Fuel

lift

Pump

1.

Fit

the

distance

piece using a

joint

on

either

side.

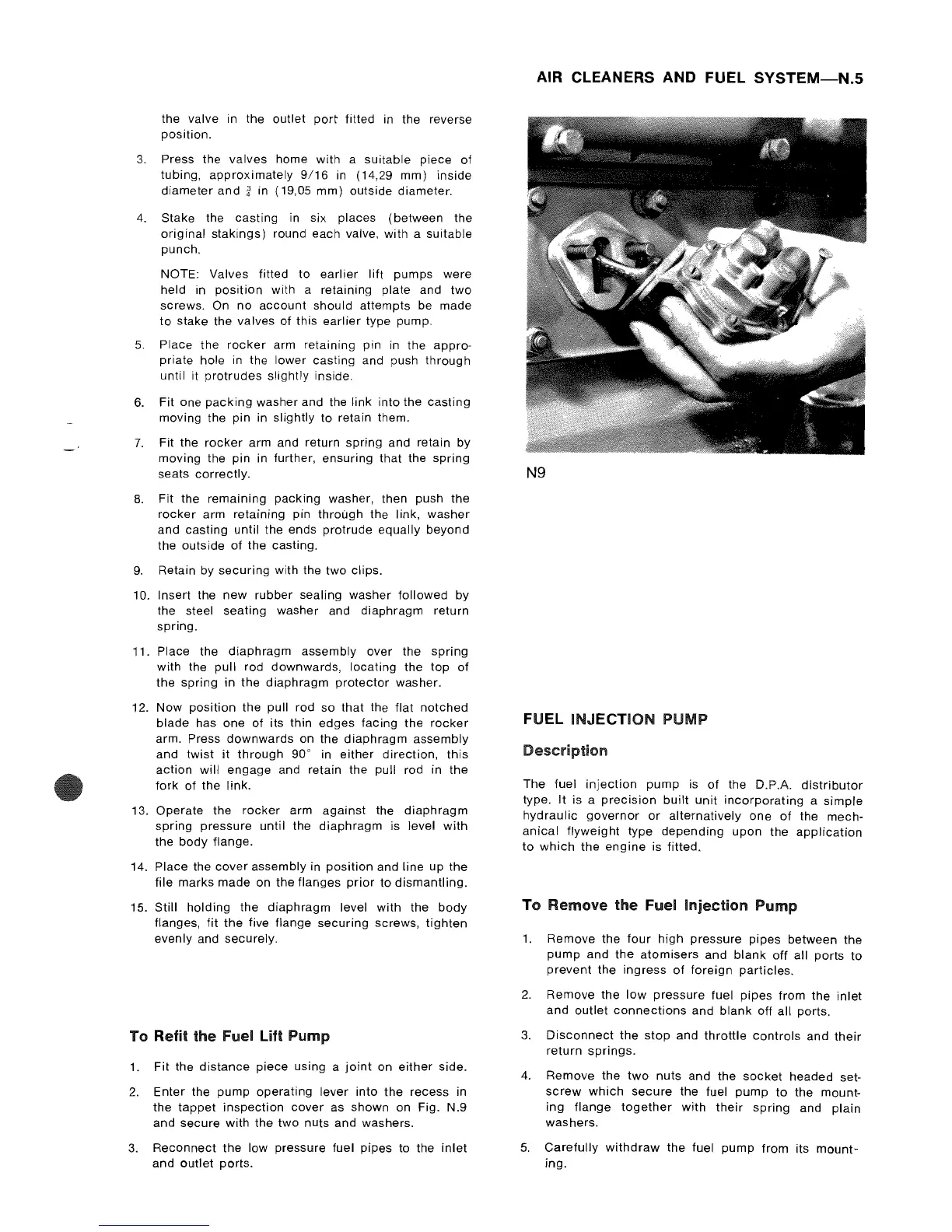

2.

Enter

the pump

operating

lever

into

the

recess in

the

tappet

inspection

cover

as shown on Fig. N.9

and

secure

with

the

two

nuts and washers.

3.

Reconnect

the

low pressure fuel pipes to the

inlet

and

outlet

ports.

AIR CLEANERS AND FUEL

SYSTEM-N.S

N9

FUEL INJECTION PUMP

Description

The fuel

injection

pump

is

of

the D.P.A.

distributor

type.

It

is a

precision

built

unit

incorporating

a

simple

hydraulic

governor

or

alternatively

one

of

the mech-

anical

flyweight

type

depending

upon

the

application

to

which

the

engine

is fitted.

To

Remove

the

Fuel

Injection

Pump

1. Remove

the

four

high

pressure

pipes

between

the

pump

and

the

atomisers

and

blank

off all

ports

to

prevent

the

ingress

of

foreign

particles.

2.

Remove the

low

pressure

fuel

pipes

from

the

inlet

and

outlet

connections

and

blank

off all ports.

3.

Disconnect

the

stop

and

throttle

controls

and

their

return

springs.

4.

Remove the

two

nuts and the

socket

headed set-

screw

which

secure

the fuel

pump

to

the mount-

ing

flange

together

with

their

spring

and plain

washers.

5.

Carefully

withdraw

the fuel

pump

from

its

mount-

ing.

Loading...

Loading...