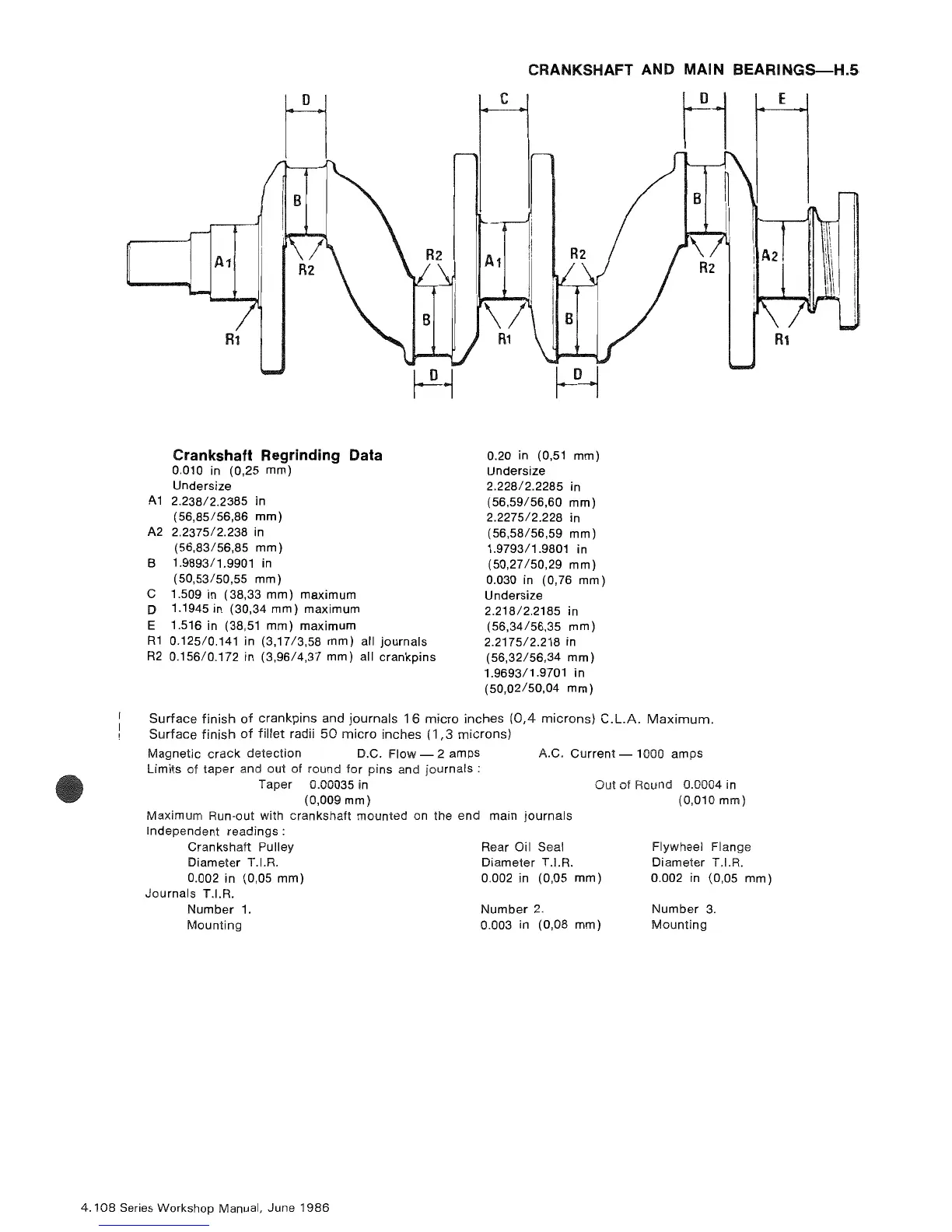

CRANKSHAFT AND MAIN

BEARINGS-H.5

Crankshaft Regrinding Data

0.010 in (0,25

mm)

Undersize

Ai 2.238/2.2385 in

(56,85/56,86

mm)

A2 2.2375/2.238 in

(56,83/56,85

mm)

B 1.9893/1.9901 in

(50,53/50,55

mm)

C 1.509 in (38,33

mm)

maximum

D 1.1945 in (30,34

mm)

maximum

E 1.516 in (38,51

mm)

maximum

R1

0.12510.141 in (3,1713,58

mm)

all

journals

R2

0.156/0.172 in (3,96/4,37

mm)

all crankpins

c

0.20 in (0,51

mm)

Undersize

2.228/2.2285 in

(56.59/56,60

mm)

2.2275/2.228 in

(56,58/56,59

mm)

1.9793/1.9801 in

(50,27/50,29

mm)

0.030 in (0,76

mm)

Undersize

2.21812.2185 in

(56,34/56,35

mm)

2.2175/2.218 in

(56,32/56,34

mm)

1.9693/1.9701

in

(50,02/50,04

mm)

Surface

finish

of

crankpins

and

journals

16

micro

inches

(0,4

microns)

C.L.A.

Maximum.

Surface

finish

of

fillet

radii

50

micro

inches

(1

,3

microns)

Magnetic

crack

detection D.C. Flow 2 amps

Limits of

taper

and out of round

for

pins and

journals:

Taper 0.00035 in

(0,009

mm)

A.C.

Current

- 1000 amps

Out of Round 0.0004 in

(0,010

mm)

Maximum Run-out with crankshaft mounted on the end main

journals

Independent

readings:

Crankshaft Pulley

Diameter T.I.R.

0.002 in (0,05

mm)

Journals

T.I.R.

Number

1.

Mounting

4.108

Series Workshop Manual, June

1986

Rear Oil Seal

Diameter T.I.R.

0.002 in (0,05

mm)

Number

2.

0.003 in (0,08

mm)

Flywheel Flange

Diameter T.I.R.

0.002 in (0,05

mm)

Number

3.

Mounting

E

Loading...

Loading...