AIR CLEANERS AND FUEL

SYSTEM-N.4

Pressure Checking

of

Fuel Lift Pump

in

Position

Fit a 0-10

Ibflin

2

(0-0,7

kgflcm2)

or

0-70

kN/m

2

pressure

gauge to

the

outlet

of the pump. Ensure that

there

are

no leaks at the

connections

between pump and gauge.

Crank

the engine

for

10 seconds and note the maximum

reading on the gauge. If the pressure recorded is less

than

75%

of the

minimum

production

static

pressure

shown below,

then

rectify the pump. Also observe the

rate at

which

the pressure

drops

to

half

the maximum

figure obtained

when

cranking

has ceased. If less than

30 seconds, rectFfy the pump.

4

bolt

type

2

bolt

type

Minimum

Production

Static Pressure

Ibflin

2

kgflcm2

kN/m

2

6 0,42

41

6 0,42

41

To Remove the Lift Pump

Minimum

Test Pressure

(75%

of Minimum

Production

Pressure)

Ibflin

2

kgflcm2

kN/m

2

4.5

0,31

31

4.5 0,31

31

1.

Disconnect

the pipes from

the

inlet

and

outlet

ports. Seal the

ends

of

the

pipes

to

prevent the

entry

of

foreign

matter.

2.

Remove the

two

nuts and washers

holding

the

pump

to

the

tappet

inspection cover.

Withdraw

the

pump,

distance

piece

and joints.

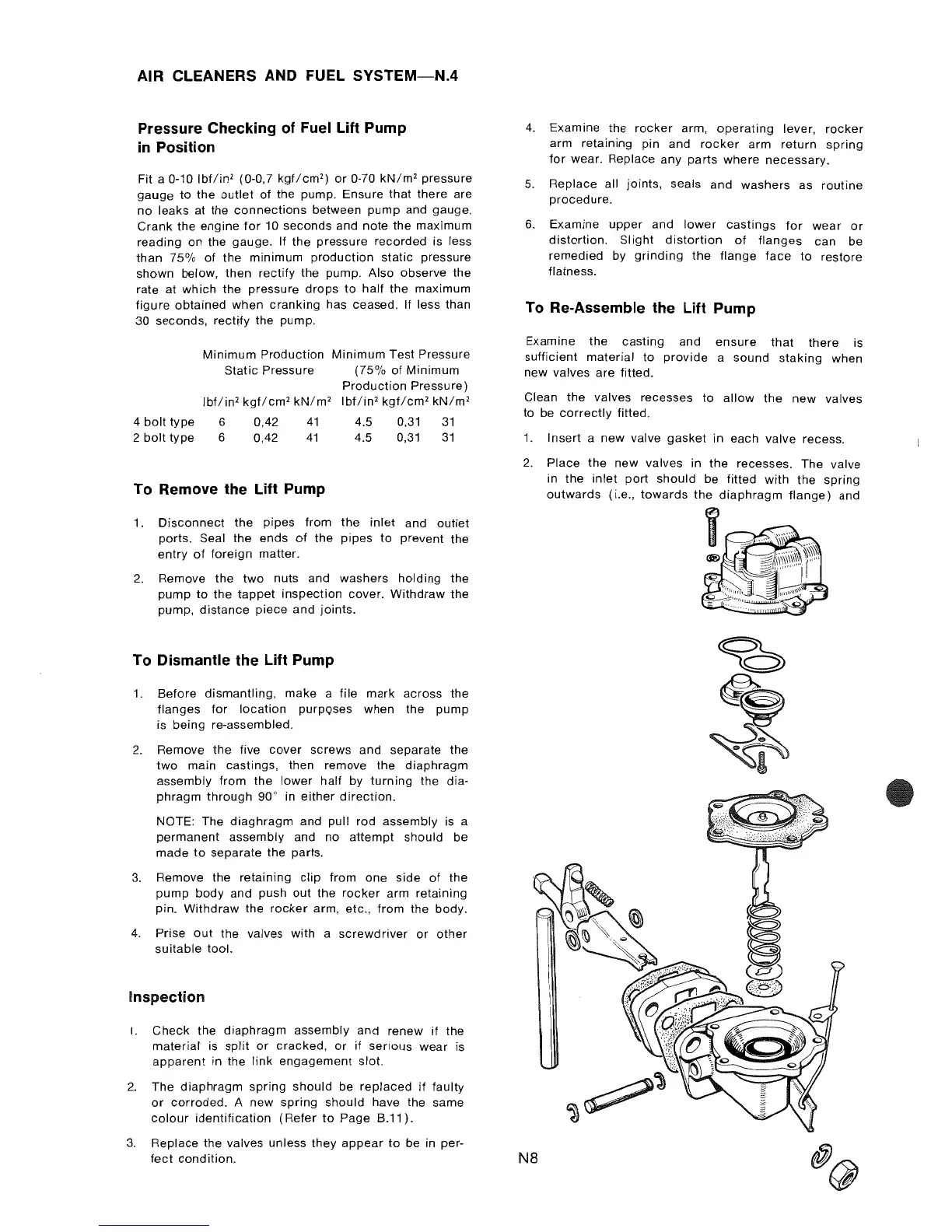

To Dismantle the Lift Pump

1. Before dismantling, make a file

mark

across

the

flanges

for

location

purposes when the

pump

is

being

re-assembled.

2.

Remove the five

cover

screws

and

separate the

two

main castings, then remove

the

diaphragm

assembly

from

the

lower

half by

turning

the dia-

phragm

through

90'

in

either

direction.

NOTE: The

diaghragm

and pull rod assembly is a

permanent

assembly and no

attempt

should be

made

to

separate

the

parts.

3.

Remove the retaining

clip

from one

side

of the

pump

body

and push

out

the

rocker

arm retaining

pin.

Withdraw

the

rocker

arm, etc., from the body.

4.

Prise

out

the valves with a

screwdriver

or

other

suitable

tool.

Inspection

I.

Check

the

diaphragm

assembly

and

renew if the

material is

split

or

cracked,

or

if

serious wear is

apparent

in the

link

engagement

slot.

2. The

diaphragm

spring

should

be

replaced

if

faulty

or

corroded.

A

new

spring

should

have the same

colour

identification

(Refer

to

Page

B.11).

3.

Replace the valves unless they

appear

to

be in per-

fect

condition.

4.

Examine the

rocker

arm,

operating

lever,

rocker

arm retaining pin

and

rocker

arm

return

spring

for

wear. Replace any

parts

where

necessary.

5.

Replace all joints,

seals

and

washers

as

routine

procedure.

6. Examine upper and

lower

castings

for

wear

or

distortion.

Slight

distortion

of

flanges

can

be

remedied by

grinding

the

flange

face

to restore

flatness.

To Re-Assemble the Lift Pump

Examine the casting and

ensure

that

there is

sufficient material to

provide

a sound

staking

when

new valves

are

fitted.

Clean the valves recesses to

allow

the

new

valves

to be

correctly

fitted.

1.

Insert a

new

valve

gasket

in each valve recess.

2.

Place

the

new

valves in

the

recesses. The valve

in the

inlet

port

should

be fitted

with

the

spring

outwards

(i.e.,

towards

the

diaphragm

flange)

and

N8

Loading...

Loading...