CRANKSHAFT AND MAIN

BEARINGS-H.4

3.

Place the

crankshaft

in

position.

4.

Locate

the

upper

thrust

washer in

position

as

shown in Fig. H.6.

5.

Fit the three

lower

bearing shells, oil, and fit the

three main

bearing

caps in

their

respective loca-

tions.

NOTE: Ensure at this stage that the

two

lower

thrust

washer halves are positioned

correctly

either

side

of the rear f\lain bearing cap when it is fitted.

6.

Check

the main bearing setscrews

prior

to fitting

for

signs

of

stretch

or

thread damage. Where

damage

or

any

doubt

exists fit new replacements.

7.

Fit the setscrews then

tighten

evenly

to

the torque

tension

given on Page B.2.

8.

Check

that the

crankshaft

can be rotated freely, if

satisfactory

check

the

crankshaft

end float by

means of feeler gauges as shown in Fig. H.7.

Should it

not

be

within

the limits quoted on Page

B.6, then oversize thrust washers are available to

give the necessary adjustment.

(Refer

to Page H8

H.1J.

9.

Fit

new

sealing

strips

to

the rear main bearing oil

seal housings and refit the housings as

described

under

the heading

"Crankshaft

Rear End Oil

Seal"

below.

10.

Liberally

oil the crankpins, locate

the

connecting

rod bearing shells, again ensuring

their

correct

relative positions,

then

fit

the

connecting

rod caps

as

described

on Page F.5. The

crankcase

should

now

be as shown in Fig. H.2.

11. Refit the

lubricating

oil pump

complete

with suc-

tion

and delivery pipes.

(Refer

to Page

L.4).

12. Refit the sump using

new

seals and joints. (Refer

to

Page

L.1).

13. Refit the

timing

case back plate, fuel pump drive

hub, timing gears, timing

cover

and

crankshaft

front

pulley.

(Refer

to

later

text

commencing

on

Page

J.1

for

their reassembly.

14. Refit and

correctly

align the flywheel housing

as

described

on Page P.2.

15. Refit the flywheel and

starter

motor.

CRANKSHAfT REAR END

OIL

SEAL

This

sealing

arrangement

consists

of

two

half

housings

bolted

around the rear

of

the

crankshaft.

The bore

of

these housings is

machined

to

accommodate

a

rubber

cored

asbestos

strip

which, in

conjunction

with

a

right

hand helix machined between the

thrust

collar

and the

flywheel

mounting

flange to the

dimensions

given on

Page B.6,

acts

to return the

surplus

oil

reaching

the

seal. The

two

half housings fit over

this

helix and the

contact

of

the sealing

strips

with

the

crankshaft

pre-

vents leakage beyond

this

point.

NOTE: When traces

of

oil

become

apparent

from

behind

the flywheel and a faulty

rear

oil

seal is sus-

pected,

first

ensure that the

crankcase

is

breathing

normally. Any build up in

crankcase

pressure

could

cause oil to be

forced

past the rear

sealing

arrange-

ment. If

crankcase

pressure is

normal

and

new

seals

require

to

be fitted the

following

procedure

should

be

adopted

with

the

crankshaft

in

position.

1.

Set

up

a

half

housing

in the

vice

with

the seal

recess uppermost.

2.

Settle

approximately

1 in (25

mm)

of

the

strip, at

each

end,

into

the

ends

of

the

groove

ensuring

that

each

end

of

the.

strip

projects

0.01010.020

in

(0,25/0,50

mm)

beyond

the

half

housing

joint

face.

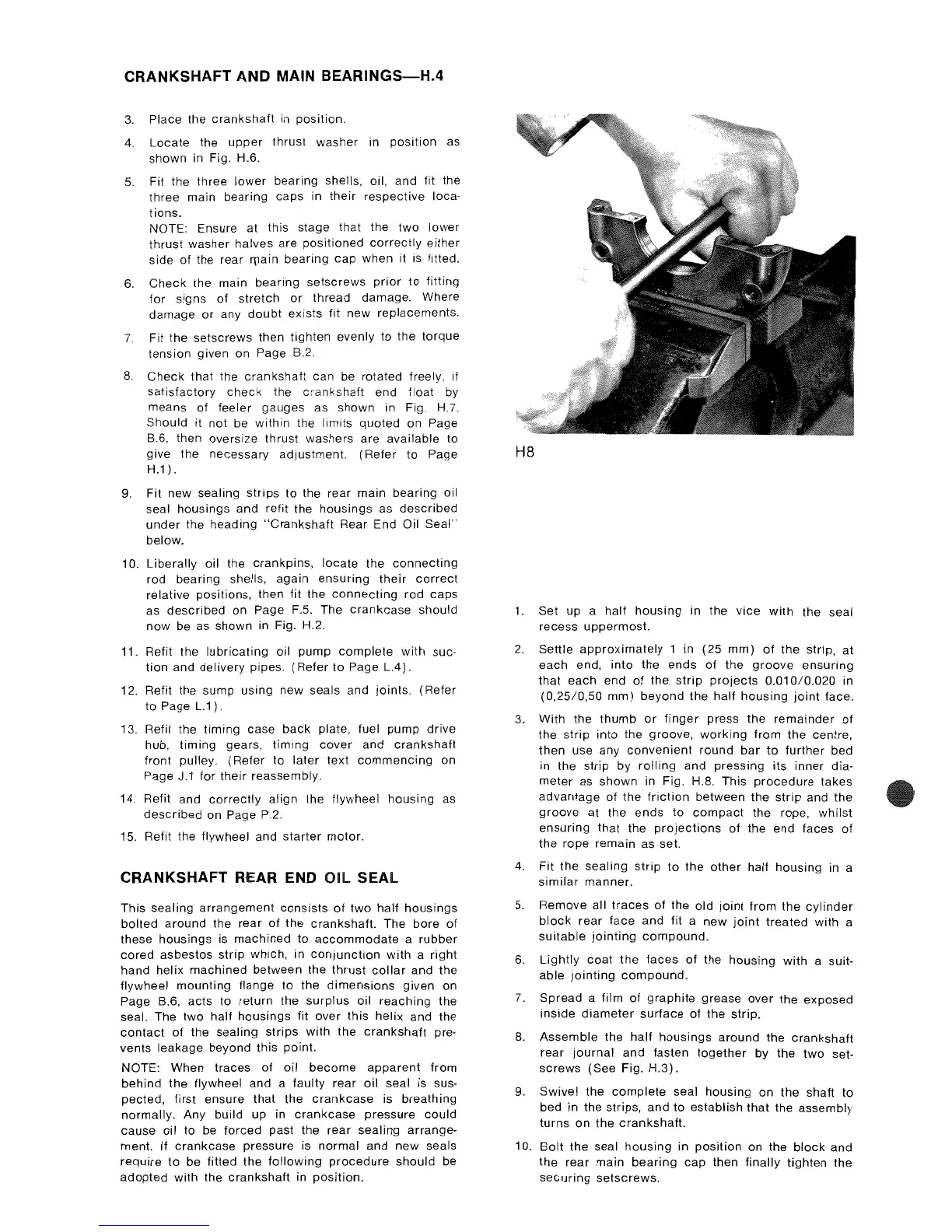

3.

With

the

thumb

or

finger

press the

remainder

of

the

strip

into the groove,

working

from

the

centre,

then use any

convenient

round

bar

to

further

bed

in the

strip

by

rolling

and

pressing its

inner

dia-

meter

as

shown

in Fig. H.8.

This

procedure

takes

advantage

of

the

friction

between the

strip

and the

groove

at the

ends

to

compact

the rope, whilst

ensuring

that the

projections

of

the

end

faces of

the

rope

remain as set.

4.

Fit

the

sealing

strip

to

the

other

half

housing in a

similar

manner.

5.

Remove all

traces

of

the old

joint

from the

cylinder

block

rear face

and

fit a

new

joint

treated with a

suitable

jointing

compound.

6.

Lightly

coat

the faces

of

the

housing

with

a suit-

able

jointing

compound.

7.

Spread

a film

of

graphite

grease

over

the exposed

inside

diameter

surface

of

the strip.

8.

Assemble

the

half

housings

around

the

crankshaft

rear

journal

and

fasten

together

by the

two

set-

screws

(See

Fig.

H.3).

9. Swivel

the

complete

seal housing

on

the

shaft

to

bed in the strips,

and

to

establish

that

the assembly

turns

on

the

crankshaft.

10.

Bolt

the seal

housing

in

position

on the

block

and

the

rear

main

bearing

cap

then

finally

tighten

the

securing

setscrews.

Loading...

Loading...