CYLINDER

HEAD-E.6

E17

~

I

•

VALVE SEAT INSERTS

Valve seat inserts

are

not

fitted to

production

engines,

but

may be fitted in service.

When fitting inserts ensure

that

only

genuine

Perkins

parts

are used.

In

order

to fit these inserts

proceed

as follows:

1.

Fit

new valve

guides

as

described

on Page E.4.

2.

Using the

new

valve

guide

bore

as a pilot,

machine

the insert recess in the

cylinder

head face to the

dimensions

shown

in Fig. E.15.

3.

Remove all

machining

swarf

and

thoroughly

clean

the insert recess

(removing

any burrs

which

may

be

present).

4.

Using the valve

guide

bore

as a

pilot

once

again

press the insert home

with

the

inserting

tool, this

tool is shown fully

dimensioned

in Fig. E.16.

NOTE: The insert must

not

under

any

circum-

stances be hammered in,

neither

should

any lubri-

cation

be used.

5. Visually

inspect

to ensure

that

the

insert has been

pressed fully home, i.e. is flush

with

the

bottom

of

the recess.

6. Recut

the

valve seat at an

included

angle of

90'

(which

will

give

the

normal

45'

seat) until

the

valve head

depth

reaches the

minimum

limit

which

is given on Page B.8.

Lightly

lap

the valve to its

new

seat.

E18

To

Dismantle the Rocker Shaft Assembly

1.

Remove the retaining

circlips

from

each

end

of

the

rocker

shaft.

2.

Withdraw

the

rocker

levers,

springs

and

support

brackets

from the

rocker

shaft.

3.

Unscrew the oil feed

pipe

from

the

banjo

and

re-

move the banjo.

(When

refitting

this

feed

pipe

it

should be noted

that

the

end

of

the

pipe

locates

the

banjo

position

on the

shaft).

Examine the

rocker

bushes and

shaft

for

wear. The

rocker

levers

should

be an easy fit on the

rocker

shaft

without

excessive

side

play.

New

rocker

levers are

supplied

complete

with

bush

fitted and reamed

to

size.

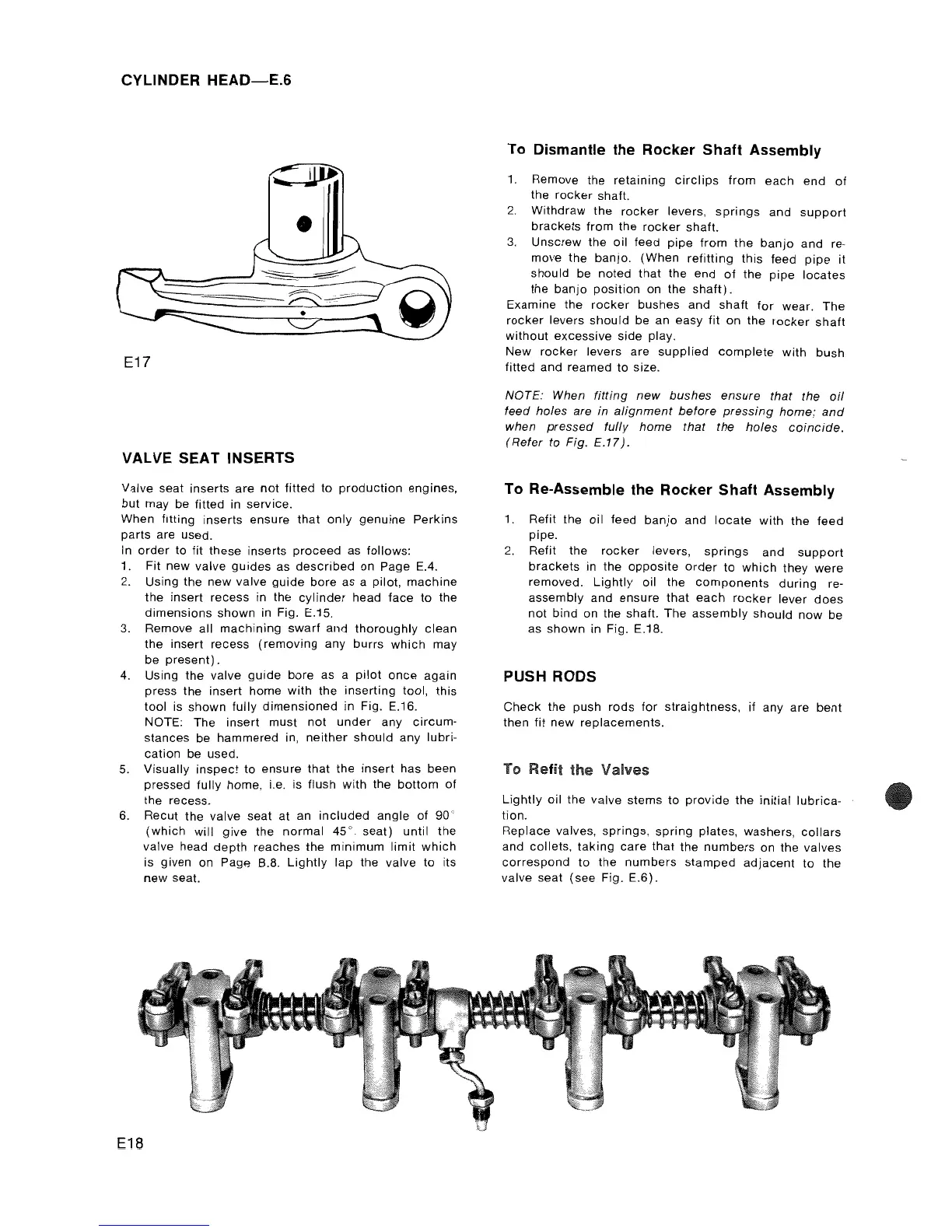

NOTE: When

fitting

new

bushes

ensure

that the

oil

feed holes are

in

alignment

before

pressing

home;

and

when

pressed

fully

home

that the

holes

coincide.

(Refer to Fig.

£,17).

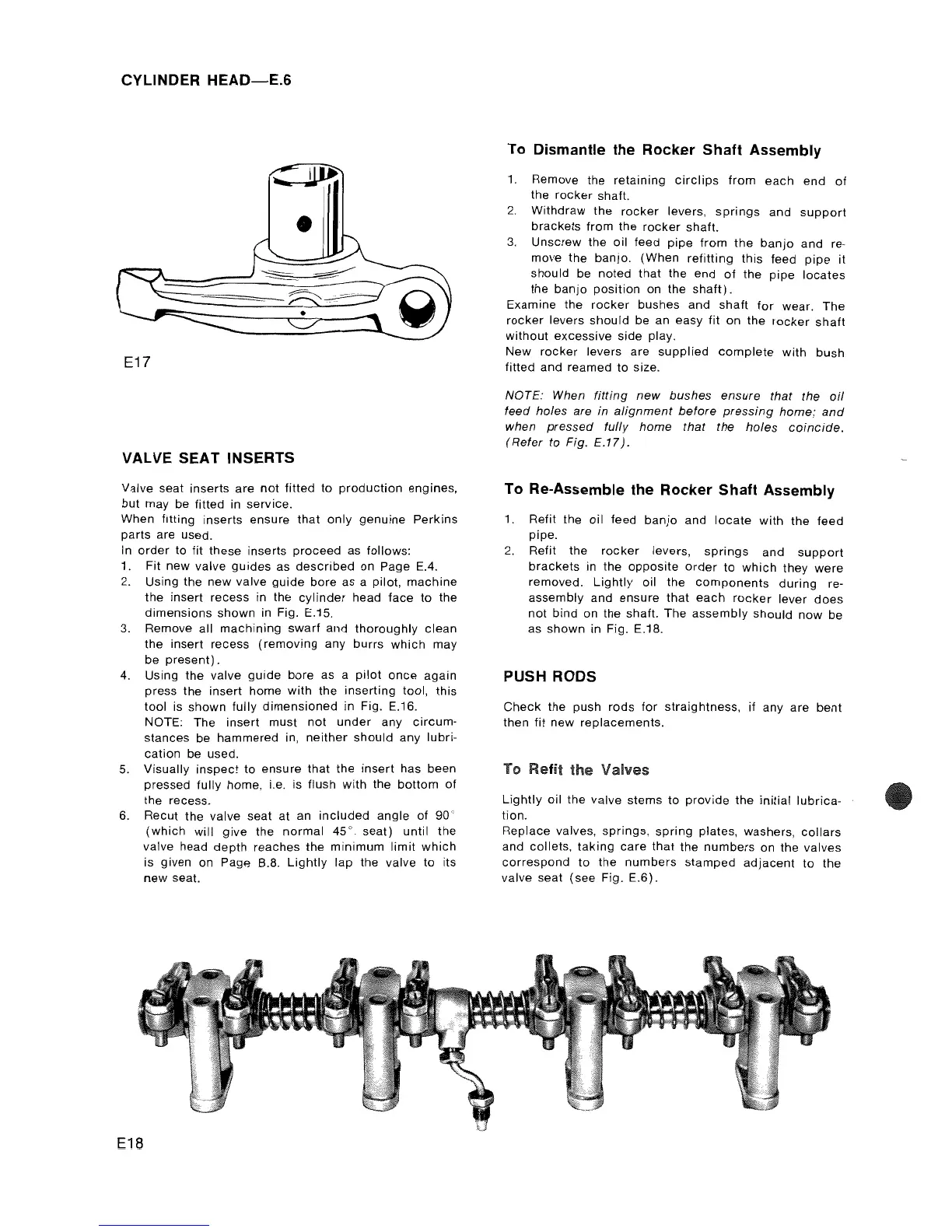

To Re-Assemble the Rocker Shaft Assembly

1.

Refit the

oil

feed

banjo

and

locate

with

the feed

pipe.

2.

Refit the

rocker

levers,

springs

and

support

brackets

in the

opposite

order

to

which

they

were

removed.

Lightly

oil

the

components

during

re-

assembly

and ensure

that

each

rocker

lever

does

not

bind

on the shaft. The

assembly

should

now

be

as shown in Fig. E.18.

PUSH RODS

Check

the push

rods

for

straightness, if any are

bent

then fit new replacements.

To Refit

the

Valves

Lightly

oil

the valve stems

to

provide

the

initial

lubrica-

tion.

Replace valves,

springs,

spring

plates, washers,

collars

and

collets,

taking

care

that the

numbers

on the valves

correspond

to the

numbers

stamped

adjacent

to

the

valve seat

(see

Fig.

E.6).

Loading...

Loading...