SECTION P

Flywheel and Flywheel Housing

To Remove

the

Flywheel

1.

Remove the gearbox,

clutch

assembly and any

linkage

as

detailed

in the service literature applic-

able

to the

particular

vehicle

or

application.

2.

Knock

back

the

locking

tabs from the flywheel

securing

setscrews.

3.

Remove the securing setscrews and

carefully

re-

move

the

flywheel from the

crankshaft

flange.

To Renew the Flywheel Ring Gear

1. The flywheel ring

gear

is a

shrunk

fit on the fly-

wheel, its removal is

carried

out by

partially

cut-

ting

through

the

gear

and chisel

cutting

it from

the

flywheel. An alternative method is

to

apply

localised

heat

to the ring gear to expand it

sufficiently

to enable

it

to

be tapped evenly from

the flywheel.

2.

The

locating

faces

of

the

flywheel

should

be

thoroughly

cleaned

to

ensure a

positive

location

when

the

new

ring

gear

is fitted.

3.

Clean, then heat the

new

ring

gear

to a tempera-

ture

not

exceeding

480°F

(250

Q

C).

4.

Fit the ring

gear

over the flywheel

with

the lead on

the

teeth facing uppermost, i.e.,

facing

away from

the

engine

when the flywheel is fitted. Rotate the

gear

quickly

on its

location

immediately

it is fitted

to ensure it is laying flat, then

allow

to

cool.

To Refit the

1"1",.11'

..

""

..

1

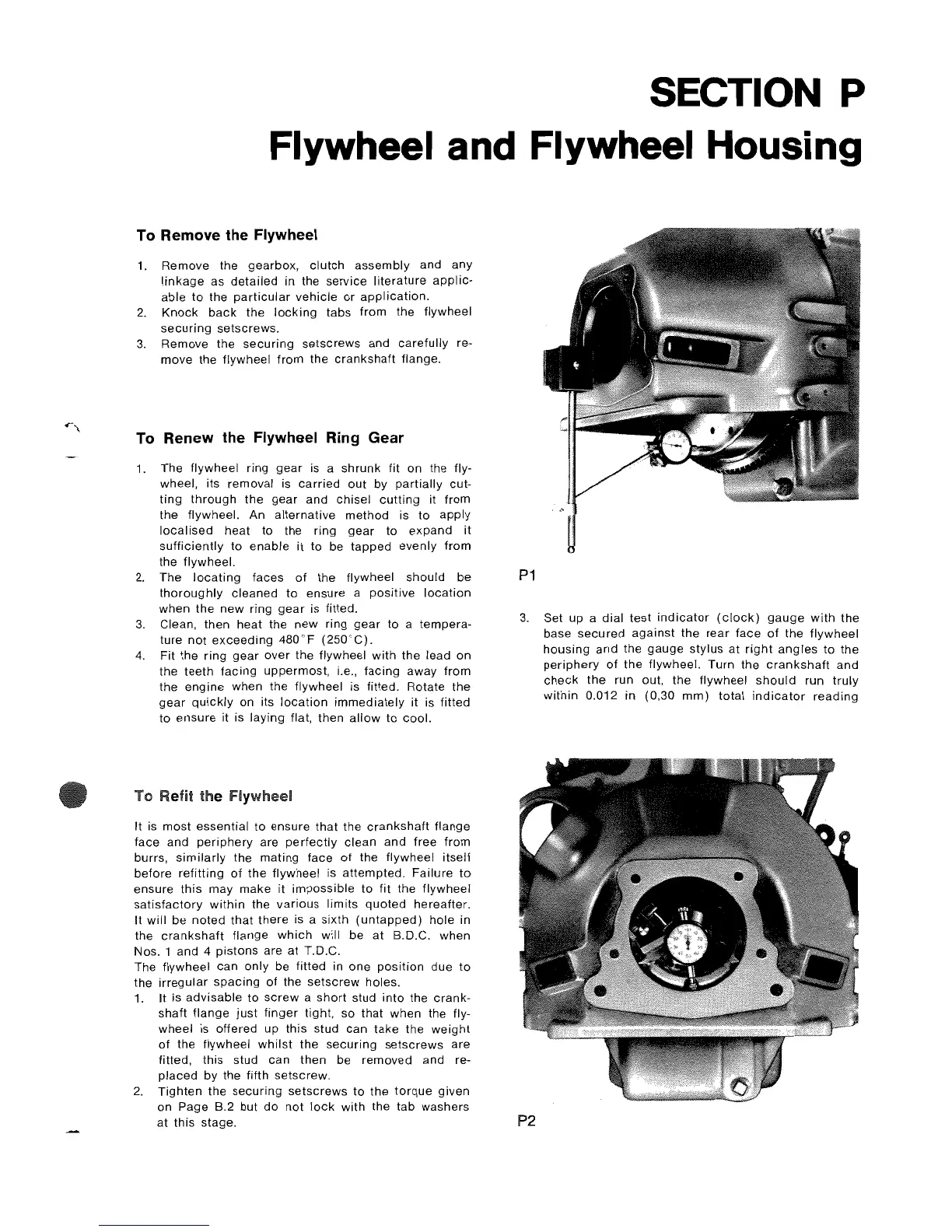

It is most essential to ensure that the

crankshaft

flange

face and

periphery

are

perfectly

clean and free from

burrs,

similarly

the mating face

of

the flywheel

itself

before refitting

of

the flywheel is attempted. Failure

to

ensure

this

may make

it

impossible

to

fit

the flywheel

satisfactory

within

the

various

limits

quoted

hereafter.

It will be noted that there is a sixth

(untapped)

hole in

the

crankshaft

flange

which

will be

at

B.D.C.

when

Nos. 1

and

4 pistons are at T.O.C.

The flywheel can only be fitted in one

position

due to

the

irregular

spacing

01

the setscrew holes.

1.

It

is

advisable

to

screw

a

short

stud

into

the crank-

shaft flange

just

finger

tight, so that when the fly-

wheel is offered up this stud can take the

weight

of

the flywheel

whilst

the

securing

setscrews

are

fitted, this stud can

then

be removed and re-

placed

by the fifth setscrew.

2.

Tighten

the

securing

setscrews

to the

torque

given

on

Page B.2

but

do

not

lock

with

the

tab

washers

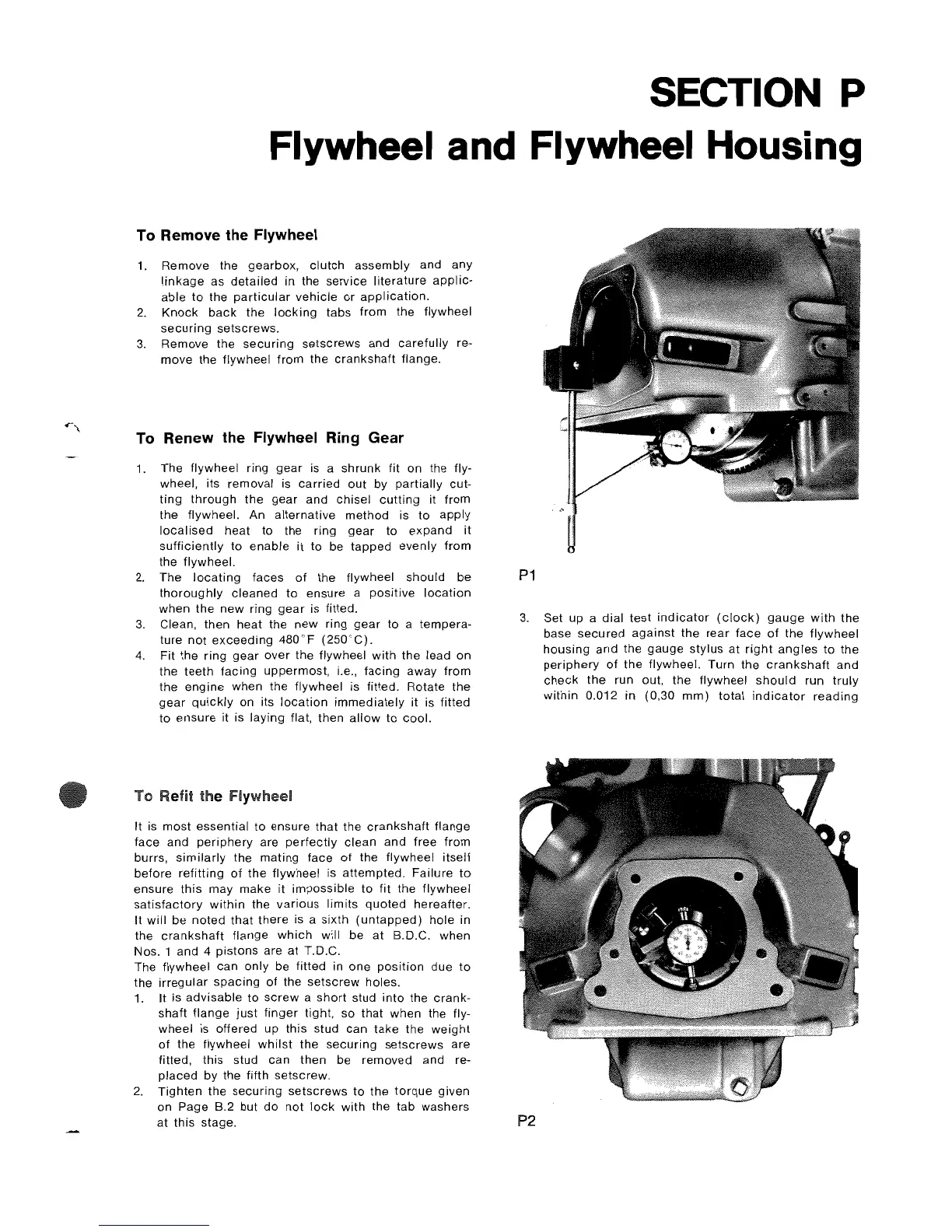

P1

3.

Set

up

a

dial

test

indicator

(clock)

gauge

with

the

base

secured

against

the

rear

face

of

the

flywheel

housing

and the

gauge

stylus

at

right

angles

to

the

periphery

of

the

flywheel. Turn the

crankshaft

and

check

the run out,

the

flywheel

should

run

truly

within

0.012 in (0,30

mm)

total

indicator

reading

at

this

stage.

P2

Loading...

Loading...