CYLINDER

HEAD-E.4

E11

COMBUSTION CHAMBER INSERTS

These can be

gently

tapped out of

their

locations

by

means

of

a short length

of

curved

bar

through

the

atomiser

bore. When refitting they must be

located

by

means of expansion washers in the recesses provided,

as shown in Figs. E.8 and E.g.

E13

Cleaning

Remove any

carbon

from the

cylinder

head.

If the

water

jacket

within

the

cylinder

head shows

signs

of

excessive scale, then a

proprietary

brand of

descaling

solution

may be used, if

possible

the

cylinder

head should be tested

for

water

leakage

after

such

treatment

at

the pressure given on Page B.7.

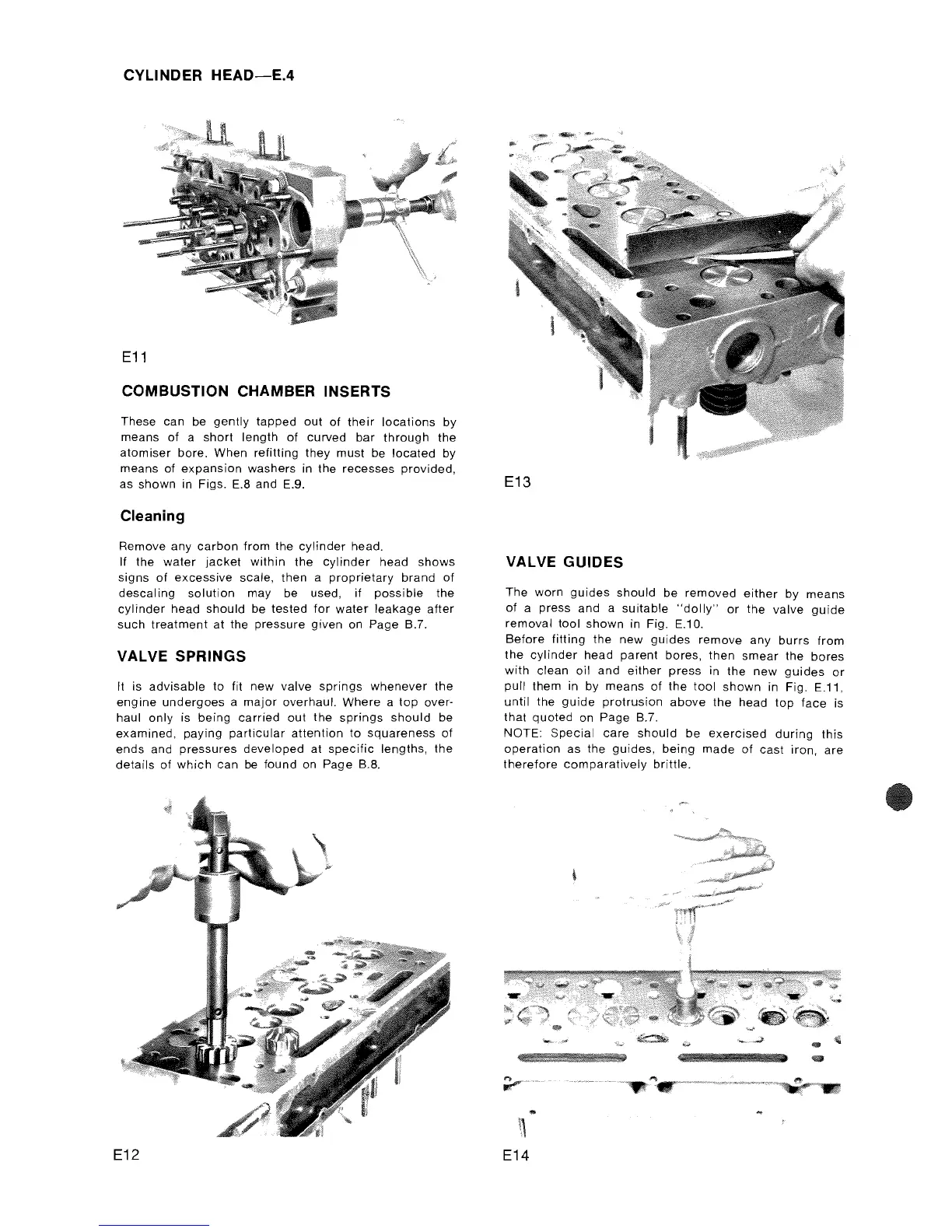

VALVE SPRINGS

It is

advisable

to fit new valve

springs

whenever the

engine

undergoes

a

major

overhaul. Where a

top

over-

haul only is

being

carried out the

springs

should

be

examined, paying

particular

attention

to

squareness

of

ends and pressures developed at

specific

lengths, the

details of

which

can

be

found on Page B.8.

E12

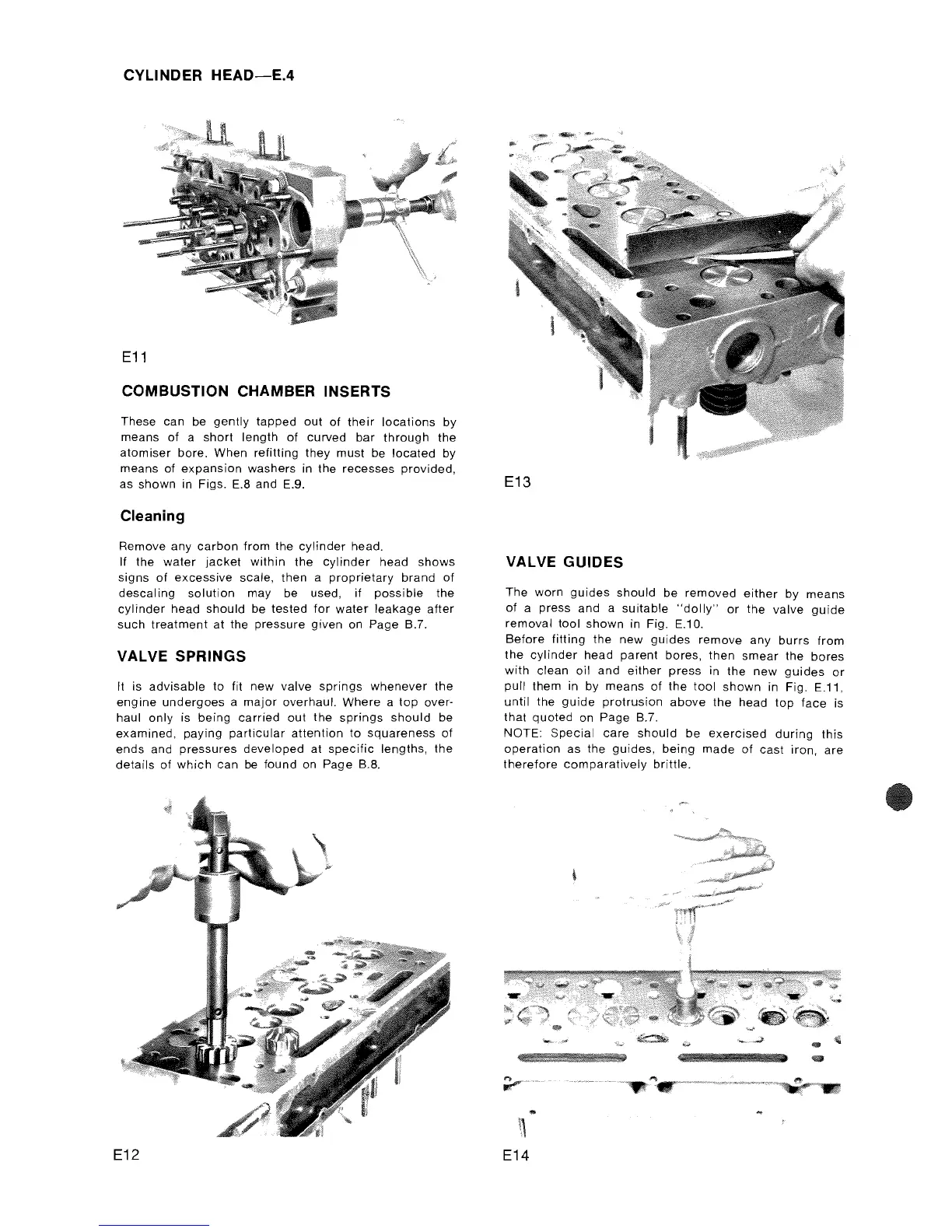

VALVE GUIDES

The worn

guides

should

be removed

either

by means

of

a press and a suitable

"dolly"

or

the valve

guide

removal tool shown in Fig. E.10.

Before fitting the

new

guides

remove any

burrs

from

the

cylinder

head

parent

bores,

then

smear

the

bores

with

clean oil and

either

press

in the

new

guides

or

pull them in by means

of

the

tool

shown

in Fig. E.11,

until

the

guide

protrusion

above the head

top

face is

that quoted on Page B.7.

NOTE: Special

care

should

be

exercised

during

this

operation

as the guides,

being

made

of

cast iron, are

therefore

comparatively

brittle.

E14

Loading...

Loading...