Fuel Pipes

(High

Pressure)

When replacing the fuel pipes it should

be

noted that

no two pipes are the same, each

is

formed to suit

an

individual atomiser position. This is important when

ordering a replacement pipe, as each one has a

different part number.

High pressure fuel pipes are now supplied with formed

ends instead of olives. The earlier pipes supplied with

olives were fitted as shown in Fig. N.21. Originally the

olives were fitted in the reverse position, but both

positions are satisfactory if undamaged.

N21

The pipes should be clean,

(wash

in clean fuel oil and

blow

through

the

fine

bore

with

compressed air

if

there

is

any

doubt),

the

olives

at

each end should

not

be split

or

unduly

compressed,

otherwise

leakage

will

result and a

new

pipe

will

be needed.

Ensure when fitting, that the pipe fits squarely at both

ends and that the union nuts are tightened firmly but

not over-tightened.

The correct tightening torque

for

high pressure fuel

pipe nuts is

15

Ibf ft

(2,1

kgf m)

or

20

Nm.

When changing an atomiser always remove the pipe

completely.

The air must

be

vented from the fuel system whenever

any part

of

the system between the fuel tank and in-

jection pump has been disconnected

for

any reason,

or

when the system has been emptied of fuel.

No

attempt

must

be made

to

start

the

engine

until

the

injection

pump

has been filled and primed as serious

damage can be caused

to

the

pump

due

to

lack

of

lubrication.

The method of priming detailed below, ensures that

only fuel which has passed through the paper filter

element can reach the interior of the pump.

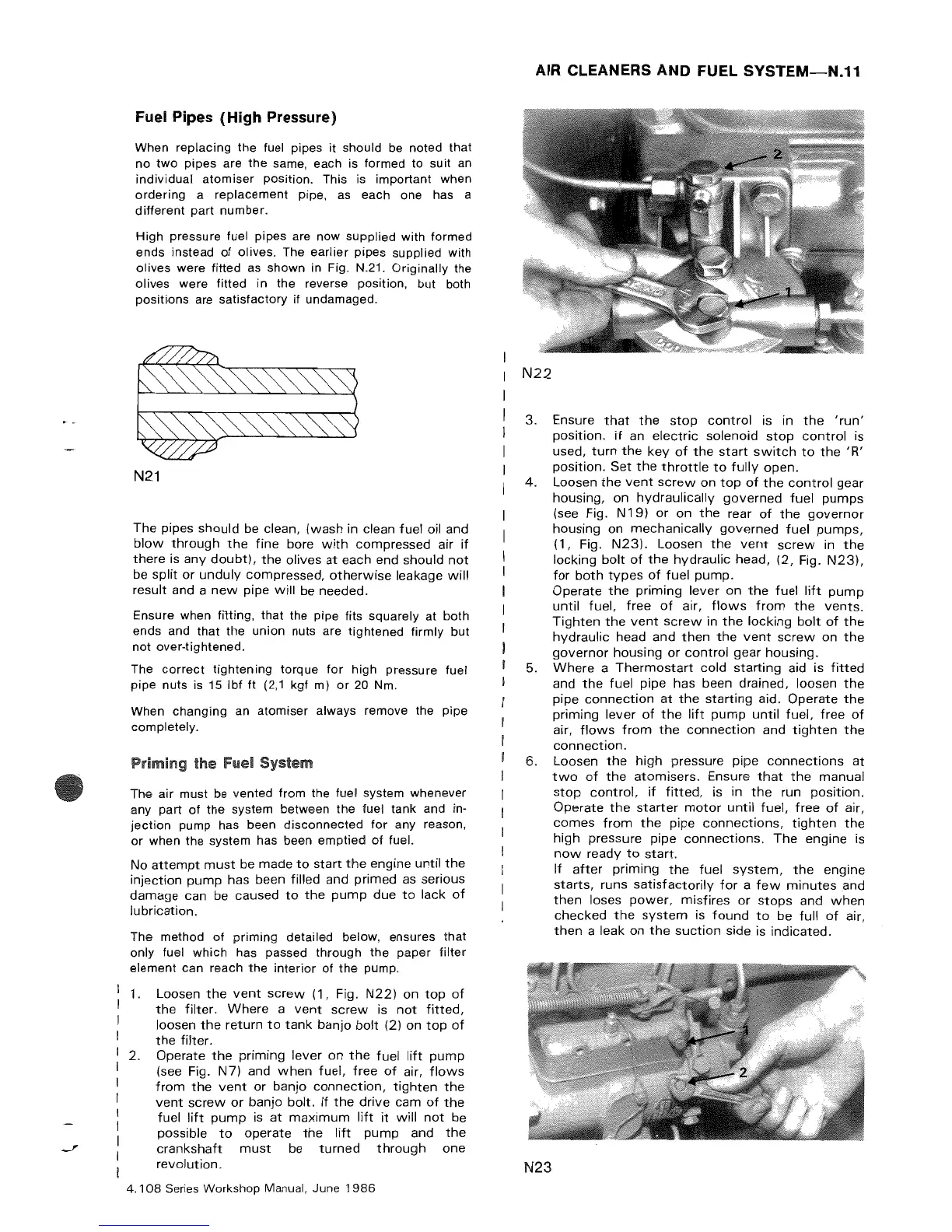

1. Loosen

the

vent

screw

(1, Fig.

N22)

on

top

of

the

filter.

Where

a

vent

screw

is

not

fitted,

loosen

the

return

to

tank

banjo

bolt

(2) on

top

of

the

filter.

2. Operate

the

priming lever

on

the

fuel

lift

pump

(see Fig.

N7)

and

when

fuel,

free

of

air,

flows

from

the

vent

or

banjo

connection,

tighten

the

vent

screw

or

banjo bolt. If

the

drive

cam

of

the

fuel

lift

pump

is

at

maximum

lift

it

will

not

be

possible

to

operate

the

lift

pump

and

the

-'

crankshaft

must

be

turned

through

one

revolution.

4.108

Series

Workshop Manual, June

1986

AIR

CLEANERS AND FUEL

SYSTEM-N.11

N22

3. Ensure

that

the

stop

control

is in

the

'run'

position.

if

an

electric

solenoid

stop

control

is

used,

turn

the

key

of

the

start

switch

to

the

'R'

position.

Set

the

throttle

to

fully

open.

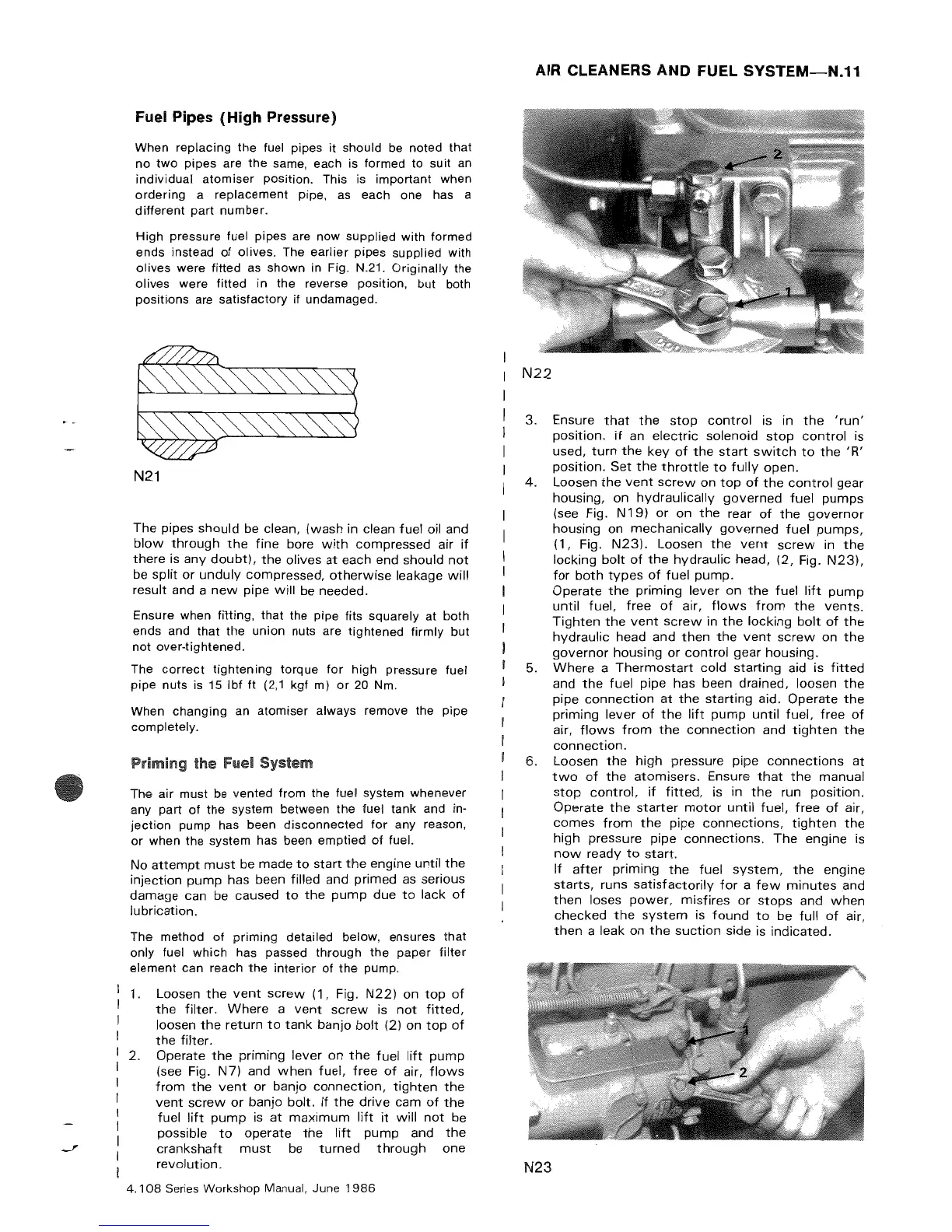

4.

Loosen

the

vent

screw

on

top

of

the

control

gear

housing, on

hydraulically

governed

fuel

pumps

(see Fig. N

19)

or

on

the

rear

of

the

governor

housing on

mechanically

governed

fuel

pumps,

(1, Fig.

N23).

Loosen

the

vent

screw

in

the

locking

bolt

of

the

hydraulic

head,

(2,

Fig.

N23),

for

both

types

of

fuel

pump.

Operate

the

priming

lever on

the

fuel

lift

pump

until

fuel,

free

of

air,

flows

from

the

vents.

Tighten

the

vent

screw

in

the

locking

bolt

of

the

hydraulic

head and

then

the

vent

screw

on

the

governor

housing

or

control

gear

housing.

5.

Where

a

Thermostart

cold

starting

aid is

fitted

and

the

fuel pipe has been drained, loosen

the

pipe

connection

at

the

starting

aid.

Operate

the

priming

lever

of

the

lift

pump

until

fuel,

free

of

air,

flows

from

the

connection

and

tighten

the

connection.

6. Loosen

the

pressure pipe

connections

at

N23

two

of

the

atomisers.

Ensure

that

the

manual

stop

control,

if

fitted,

is in

the

run

position.

Operate

the

starter

motor

until

fuel,

free

of

air,

comes

from

the

pipe

connections,

tighten

the

high

pressure pipe

connections.

The

engine is

now

ready

to

start.

If

after

priming

the

fuel

system,

the

engine

starts,

runs

satisfactorily

for

a

few

minutes

and

then

loses

power,

misfires

or

stops

and

when

checked

the

system

is

found

to

be

full

of

air,

then

a leak

on

the

suction

side is indicated.

Loading...

Loading...