TIMING CASE AND

DRIVE-J.G

To Refit the Tappets and Camshaft

1.

If the tappets have been removed

liberally

lubri-

cate

them with clean engine oil and return to

their

resective locations. Secure with

clips

(if

applicable)

.

2.

Carefully refit the

camshaft

into the

cylinder

block

exercising

the same care

as

used

during

its re-

moval.

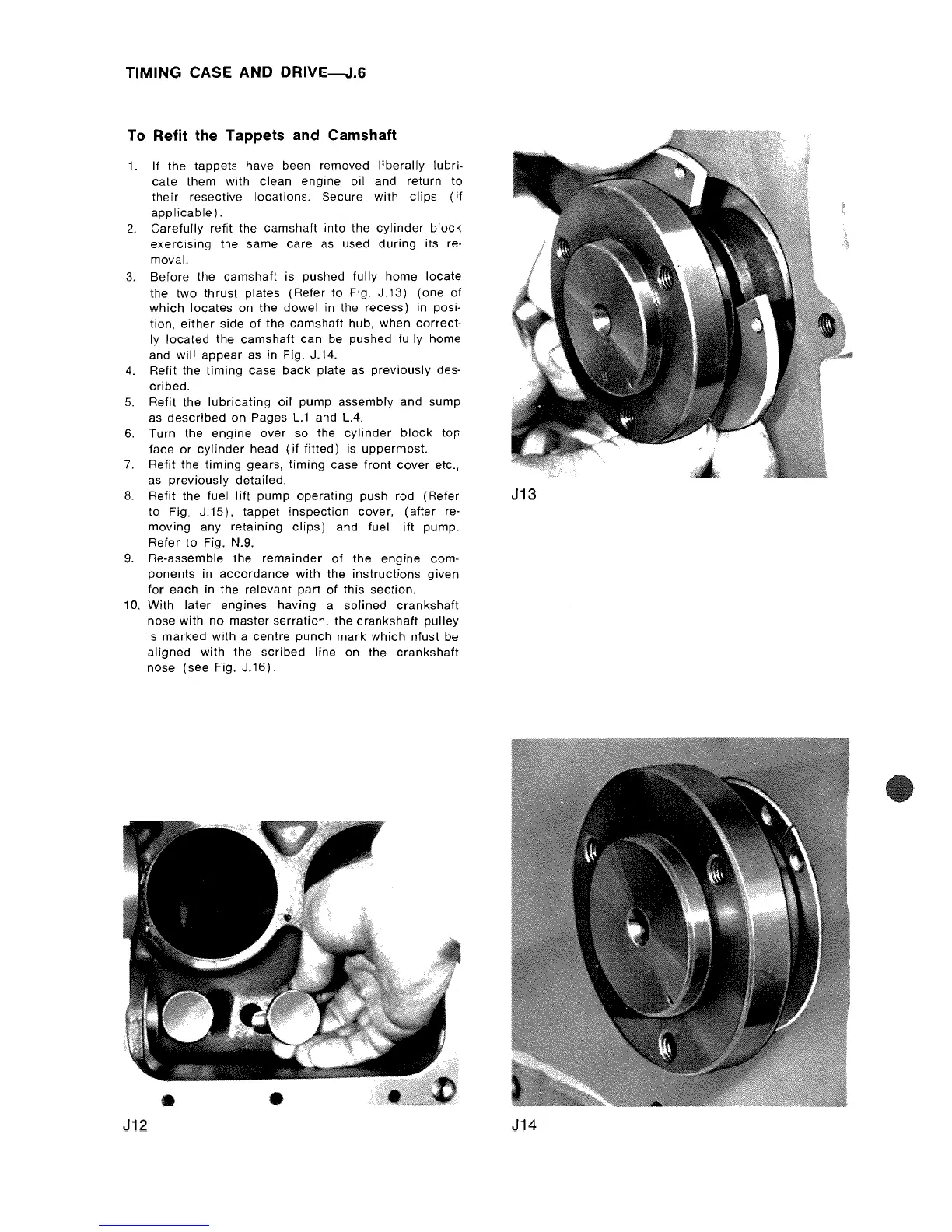

3.

Before the

camshaft

is pushed

fully

home

locate

the

two

thrust

plates (Refer

to

Fig. J.13) (one of

which

locates

on

the

dowel

in the recess) in posi-

tion,

either

side

of

the

camshaft

hub, when

correct-

ly

located

the

camshaft

can

be pushed fully home

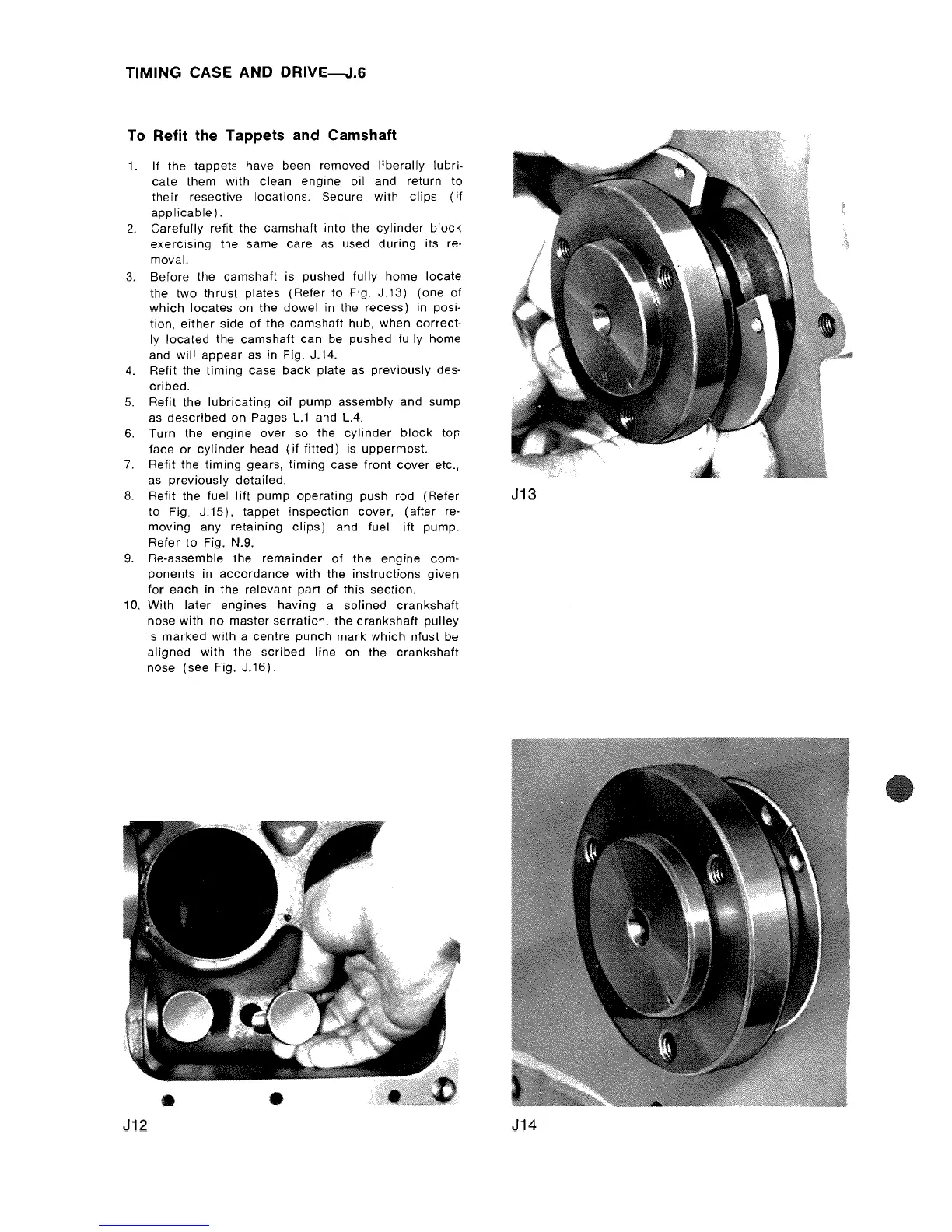

and will appear as in Fig. J.14.

4.

Refit the

timing

case

back

plate as previously des-

cribed.

5.

Refit the

lubricating

oil pump assembly and sump

as

described

on Pages

L.1

and

LA.

6.

Turn the engine over so the

cylinder

block

top

face

or

cylinder

head

(if

fitted) is uppermost.

7.

Refit the

timing

gears,

timing

case

front

cover

etc.,

as

previously

detailed.

8.

Refit the fuel

lift

pump

operating

push rod (Refer J13

to Fig.

J.15),

tappet

inspection

cover,

(after

re-

moving any retaining

clips)

and fuel

lift

pump.

Refer

to

Fig. N.9.

9.

Re-assemble the

remainder

of

the

engine

com-

ponents

in

accordance

with

the

instructions

given

for

each

in the relevant part

of

this section.

10. With

later

engines having a

splined

crankshaft

nose with

no

master serration, the

crankshaft

pulley

is

marked

with

a

centre

punch

mark

which

must be

aligned

with

the

scribed

line on

the

crankshaft

nose (see Fig.

J.16).

J12 J14

Loading...

Loading...