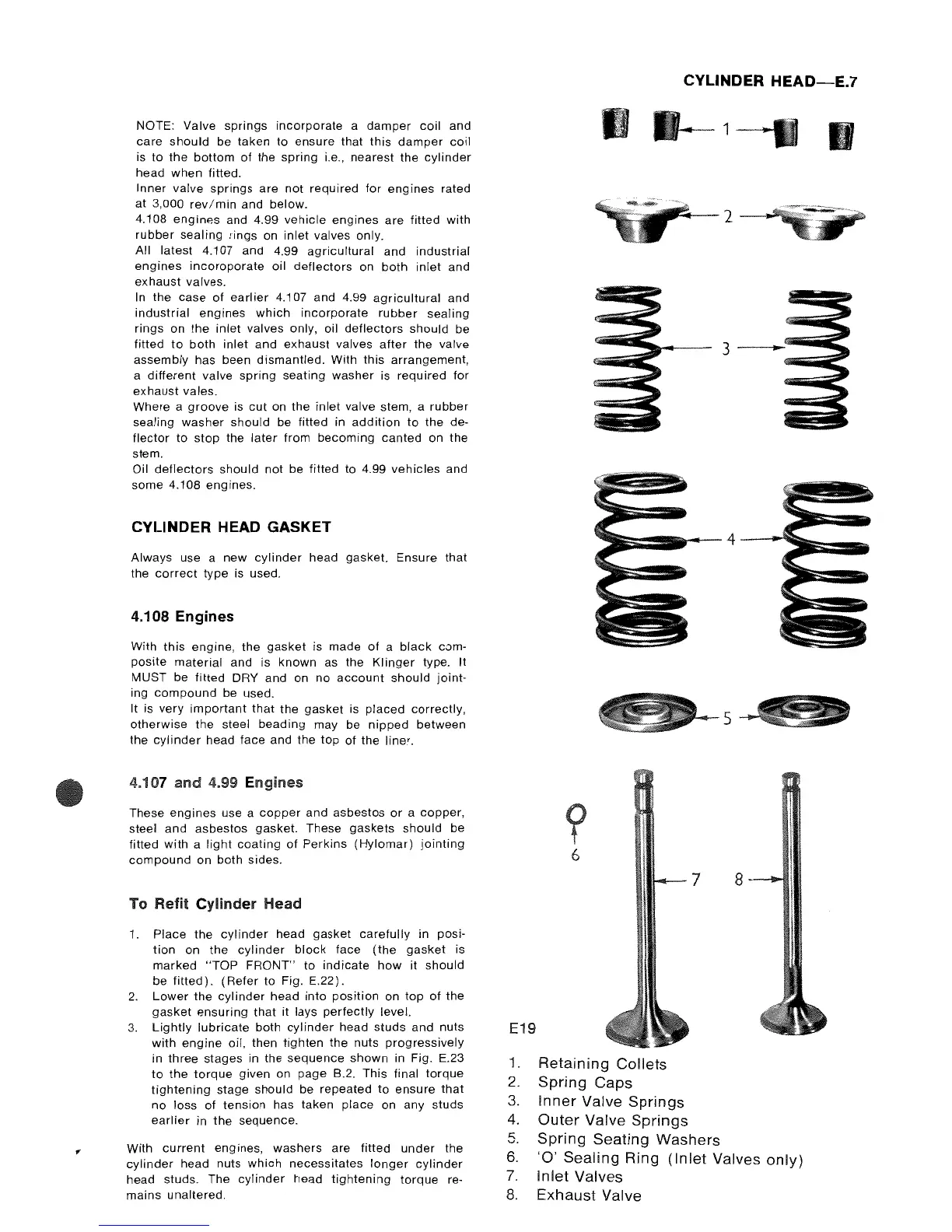

NOTE: Valve

springs

incorporate a

damper

coil

and

care

should

be

taken

to ensure that this

damper

coil

is

to

the

bottom

of

the

spring

i.e., nearest the

cylinder

head

when

fitted.

Inner valve

springs

are

not

required for engines rated

at

3,000

rev/min

and

below.

4.108

engines

and 4.99 vehicle engines are fitted with

rubber

sealing rings on

inlet

valves only.

All

latest 4.107 and 4.99

agricultural

and industrial

engines

incoroporate

oil

deflectors

on both

inlet

and

exhaust valves.

In the case

of

earlier

4.107 and 4.99

agricultural

and

industrial

engines

which

incorporate

rubber

sealing

rings

on

the

inlet

valves only, oil

deflectors

should be

fitted

to

both inlet and exhaust valves

after

the valve

assembly has been

dismantled.

With this arrangement,

a

different

valve

spring

seating washer is required

for

exhaust

vales.

Where a

groove

is

cut

on the

inlet

valve stem, a

rubber

sealing

washer

should

be fitted in

addition

to

the de-

flector

to

stop

the

later

from

becoming

canted

on the

stem.

Oil

deflectors

should not be fitted to 4.99

vehicles

and

some 4.108 engines.

CYLINDER HEAD GASKET

Always use a

new

cylinder

head gasket. Ensure that

the

correct

type is used.

4.108 Engines

With

this

engine, the

gasket

is made

of

a

black

com-

posite material and is known

as

the

Klinger

type. It

MUST be fitted DRY and on

no

account

should

joint-

ing

compound

be used.

It is very

important

that the gasket is

placed

correctly,

otherwise

the steel

beading

may be

nipped

between

the

cylinder

head face and the

top

of the liner.

4.107

and

4.99

These engines use a

copper

and asbestos

or

a copper,

steel and asbestos gasket. These gaskets

should

be

fitted

with

a

light

coating

of

Perkins

(Hylomar)

jointing

compound

on both sides.

To

Rem

Cylinder

Head

1. Place the

cylinder

head

gasket

carefully

in posi-

tion

on the

cylinder

block

face

(the

gasket

is

marked

"TOP

FRONT" to

indicate

how

it

should

be

fitted).

(Refer

to Fig. E.22).

2.

Lower

the

cylinder

head

into

position

on

top

of

the

gasket

ensuring that it lays

perfectly

level.

3.

Lightly

lubricate

both

cylinder

head

studs

and nuts

with

engine

oil, then

tighten

the nuts

progressively

in three stages in the

sequence

shown

in Fig. E.23

to

the

torque

given on page B.2.

This

final

torque

tightening

stage should be repeated to ensure

that

no

loss

of

tension has taken place on any studs

earlier

in

the

sequence.

With

current

engines,

washers

are fitted

under

the

cylinder

head nuts

which

necessitates

longer

cylinder

head studs. The

cylinder

head

tightening

torque

re-

mains

unaltered.

CYLINDER

HEAD-E.1

1

II

F"t---2

---_

3

6

7 8

E19

1.

Retaining

Collets

2.

Spring

Caps

3.

Inner

Valve

Springs

4.

Outer

Valve

Springs

5.

Spring

Seating

Washers

6.

'0'

Sealing

Ring

(Inlet

Valves

only)

7.

Inlet

Valves

8.

Exhaust

Valve

Loading...

Loading...