PSR-TRISAFE-S

2-6

PHOENIX CONTACT 103503_en_03

The table below lists the functional blocks that offer these parameters.

To configure a startup inhibit for a specific safe output, for example, this output must be

directly connected in the safety logic to the output of a safe functional block, for which the

startup inhibit is set via the parameters.

Example In the example below, EmergencyStop as well as a startup inhibit (S_RES parameter =

FALSE) and a restart inhibit (A_RES = FALSE) are specified for the safe functional block.

The OUT enable output for the functional block is connected directly to safe output O0,

where O0 offers a restart inhibit and a startup inhibit. (EmergencyStop executes stop

category 0 at the output, which is also transmitted to O0 by the direct connection.)

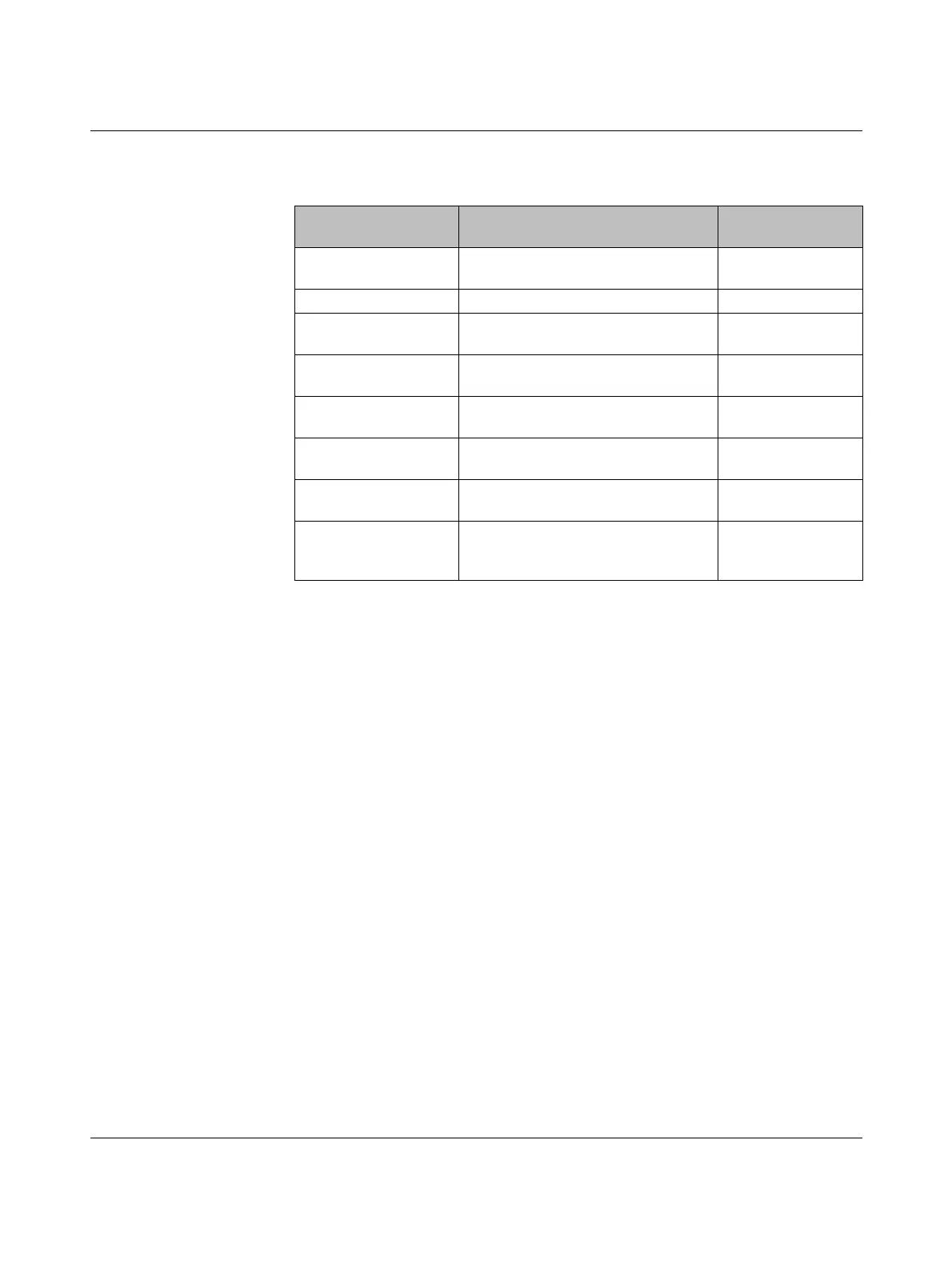

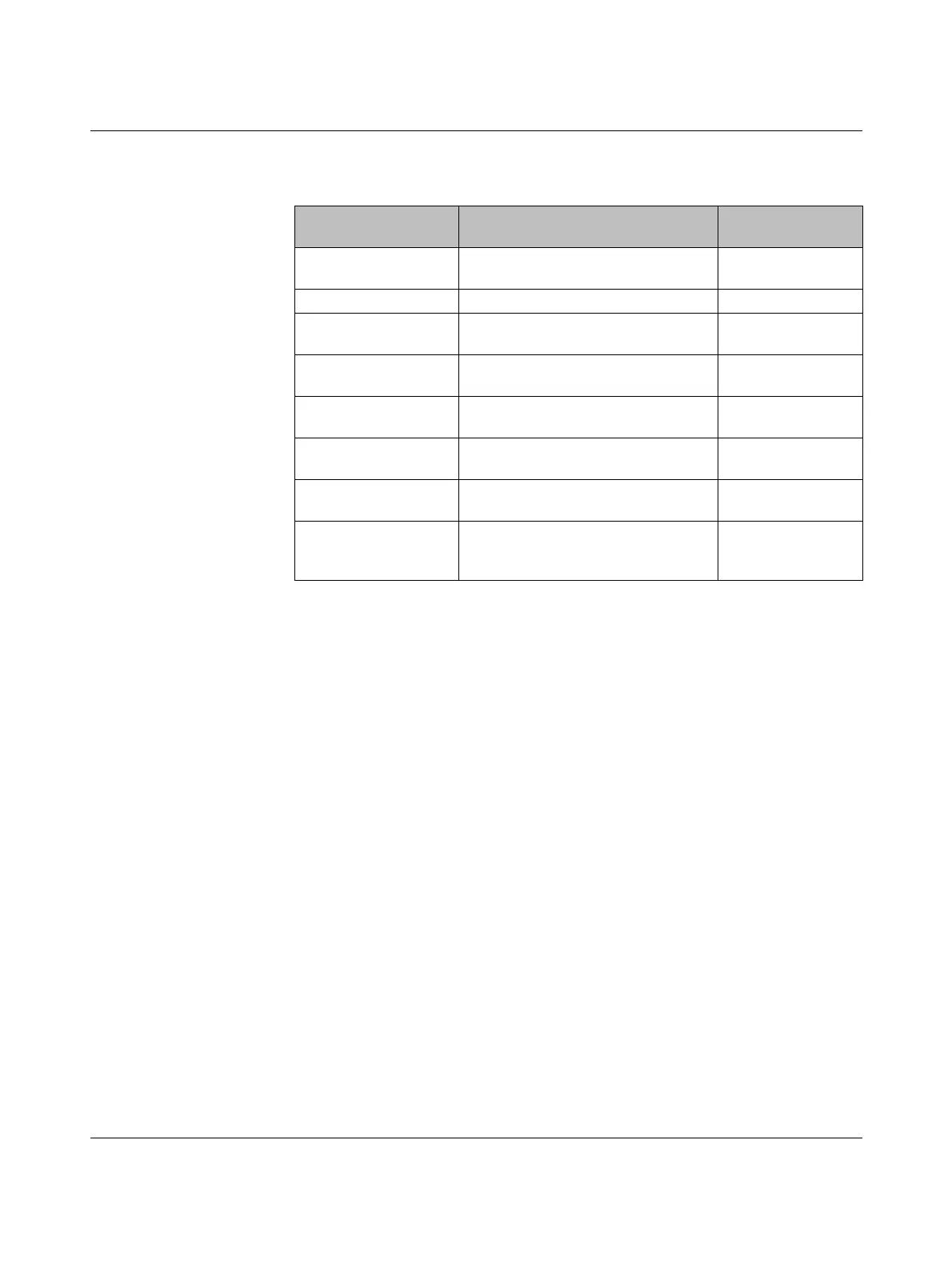

Table 2-1 Functional blocks that support a startup inhibit/restart inhibit

Functional block

name

Function Available inhibit

EmergencyStop Emergency stop monitoring Startup inhibit

Restart inhibit

EDM External device monitoring Startup inhibit

EnableSwitch Evaluation of a three-position enable

switch

Restart inhibit

ESPE Monitoring of electrosensitive

protective equipment (e.g., light grid)

Startup inhibit

Restart inhibit

GuardLocking Monitoring of safety door with four-state

interlocking

Startup inhibit

Restart inhibit

GuardMonitoring Monitoring of safety door with two-state

interlocking

Startup inhibit

Restart inhibit

MutingPar_2Sensor Monitoring of two muting sensors and

light grid

Startup inhibit

TestableSafetySensor Monitoring of a connected

optoelectronic protective device

(e.g., light curtain) with test function

Startup inhibit

Restart inhibit

Loading...

Loading...