8.2

TRANSMISSION

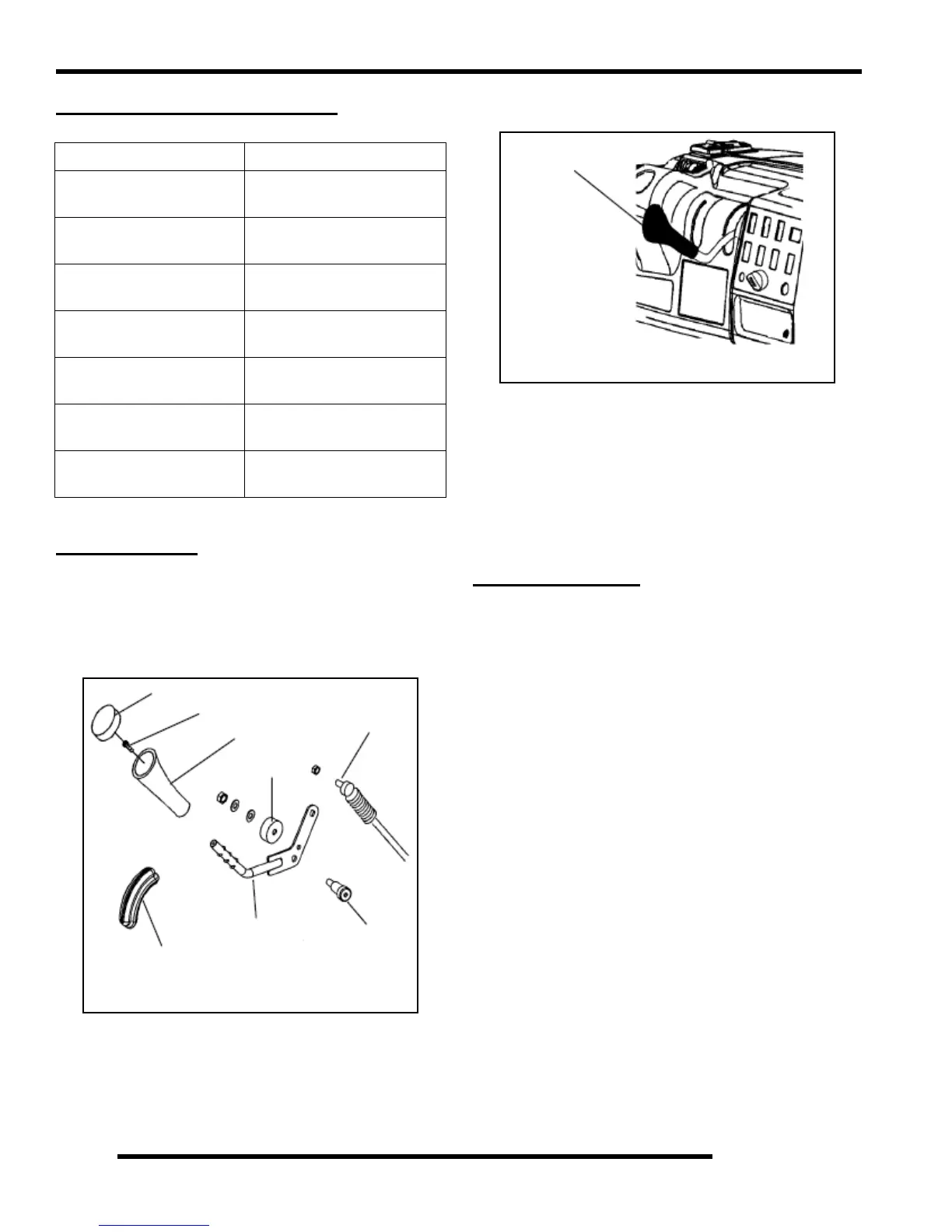

TORQUE SPECIFICATIONS

SHIFT LEVER

Removal

1. Disconnect linkage cable from shifter.

2. Remove one bolt attaching the gear shift selector mount to

machine frame.

3. Remove the shift lever cover and then remove the screw.

Pull off the shifter knob.

4. Lift the gear shift selector out of mounting bracket and

away from frame.

Installation

1. Repeat the steps in reverse order to install the gear shift

selector.

SHIFT LINKAGE

Inspection

Linkage rod adjustment is necessary when symptoms include:

• No All Wheel Drive light

• Noise on deceleration

• Inability to engage a gear

• Excessive gear clash (noise)

• Shift selectors moving out of desired range

NOTE: Remove necessary components to gain

access to shift linkage cable ends (i.e. exhaust heat

shield, exhaust pipe, etc.).

1. Inspect shift linkage cable, clevis pins, and pivot bushings

and replace if worn or damaged.

2. Be sure idle speed is adjusted properly.

ITEM TORQUE VALUE

Transmission Fill Plug

10-14 ft. lbs.

(14-19 Nm)

Transmission Drain Plug

10-14 ft. lbs.

(14-19 Nm)

Transmission Case Bolts

27-34 ft. lbs.

(37-46 Nm)

Bell Crank Nut

12-18 ft. lbs.

(16-24 Nm)

Bell Crank Gear Cover

7-9 ft. lbs.

(10-12 Nm)

Transmission Mounting

Bolts

25 ft. lbs. (35 Nm)

Transmission

Lubricant / Amount

AGL Gearcase Lube

43.6 oz. (1290 ml)

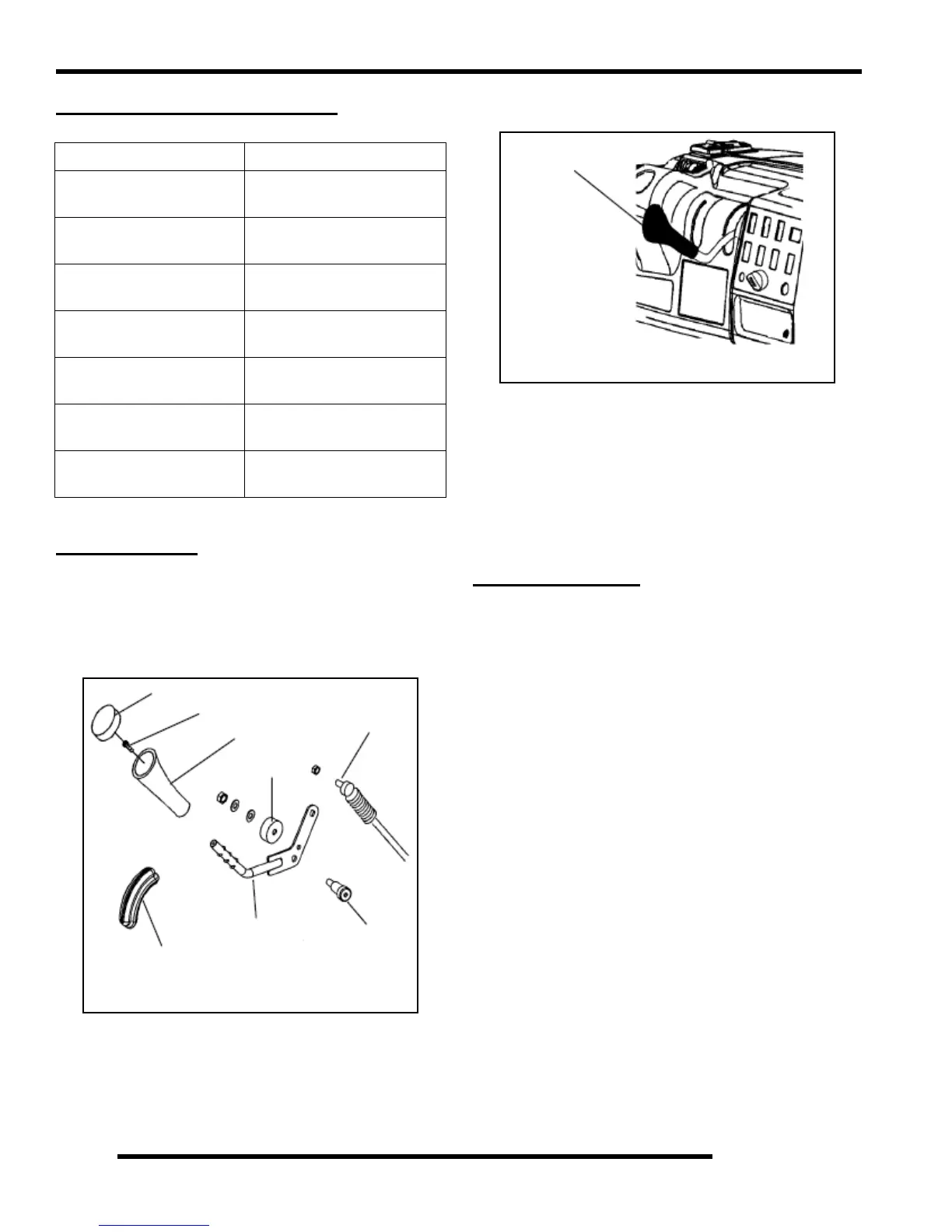

Cover

Shifter knob

Bearing

Cable

Bolt

Shifter

Grommet

Screw

Shift Lever Breakdown

Shift Lever Location

Shift Lever

Loading...

Loading...