MAINTENANCE

2.13

PILOT SCREW

The pilot system supplies fuel during engine operation with the

throttle valve closed or slightly opened. The fuel/air mixture is

metered by pilot screw and discharged into the main bore

through the pilot outlet.

PILOT SCREW ADJUSTMENT

1. Start engine and warm it up to operating temperature (about

10 minutes).

2. Turn pilot screw in (clockwise) until lightly seated. Turn

screw out the specified number of turns. NOTE: Do not

tighten the pilot screw forcefully against the seat or the

screw and/or seat will be permanently damaged.

3. Connect an accurate tachometer that will read in increments

of + or - 50 RPM such as the PET 2100DX (PN

8712100DX) or the PET 2500 (PN 8712500).

4. Set idle speed to 1200 RPM. Always check throttle cable

freeplay after adjusting idle speed and adjust if necessary.

5. Slowly turn mixture screw clockwise using the pilot screw

wrench until engine begins to miss.

CAUTION

The pilot screw is calibrated at the factory to meet

EPA / CARB regulations for air quality standards

and is sealed with a brass plug to prevent tamper-

ing. Removal of the tamper proof plug is not permit-

ted. For service purposes, cleaning of the pilot

circuit can be done only by a certified repair shop to

ensure air quality standards are not exceeded.

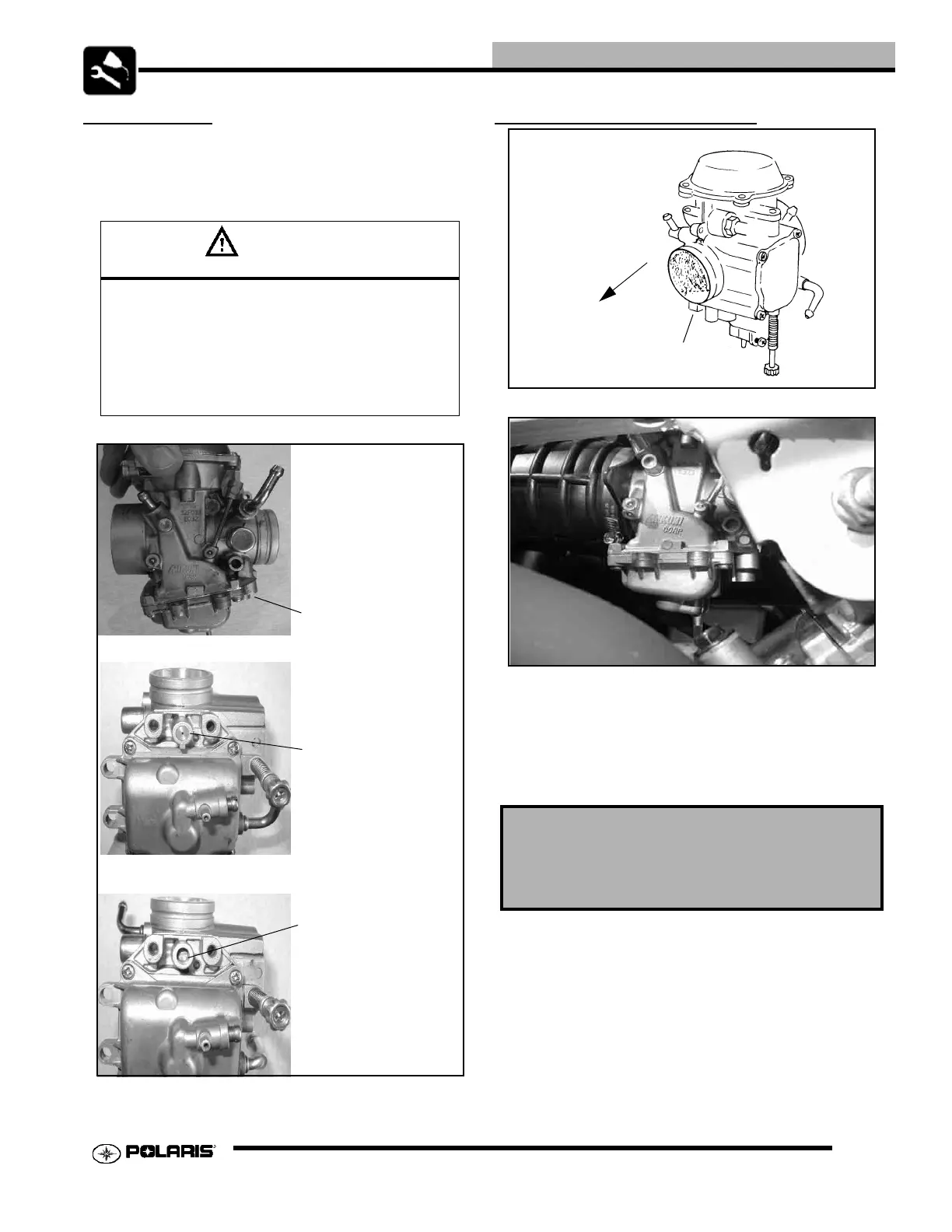

Pilot Screw Location

Brass Plug Installed

Brass Plug Removed

Pilot screws are calibrated at the factory. Each

carburetor has a slightly different pilot screw

setting. The specifications may require

additional tuning to achieve the desired results.

Pilot Screw

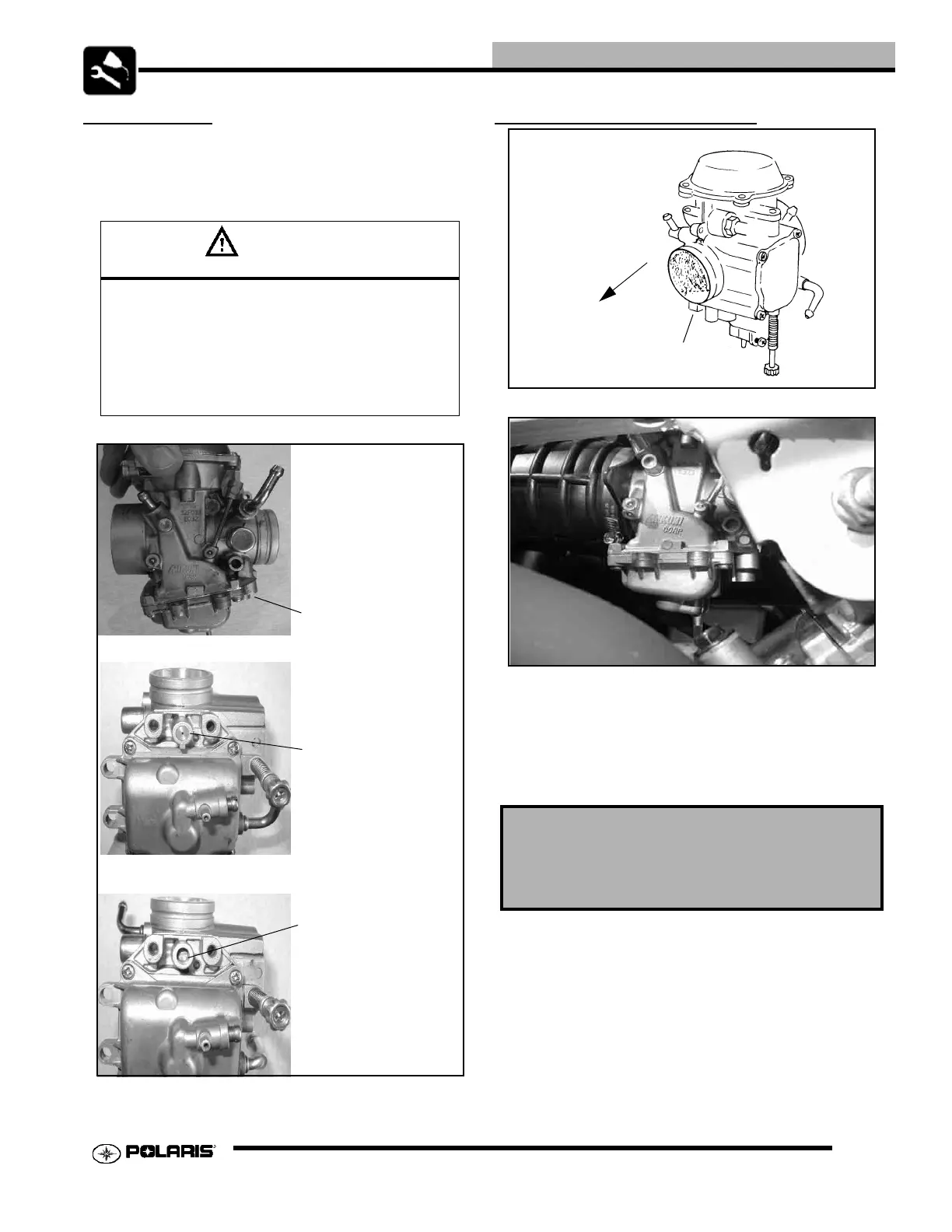

FRONT

(Engine)

Loading...

Loading...