3.27

ENGINE

If cylinder wear or damage is excessive, it will be

necessary to replace the cylinder. Hone only enough to

deglaze the outer layer of the cylinder bore.

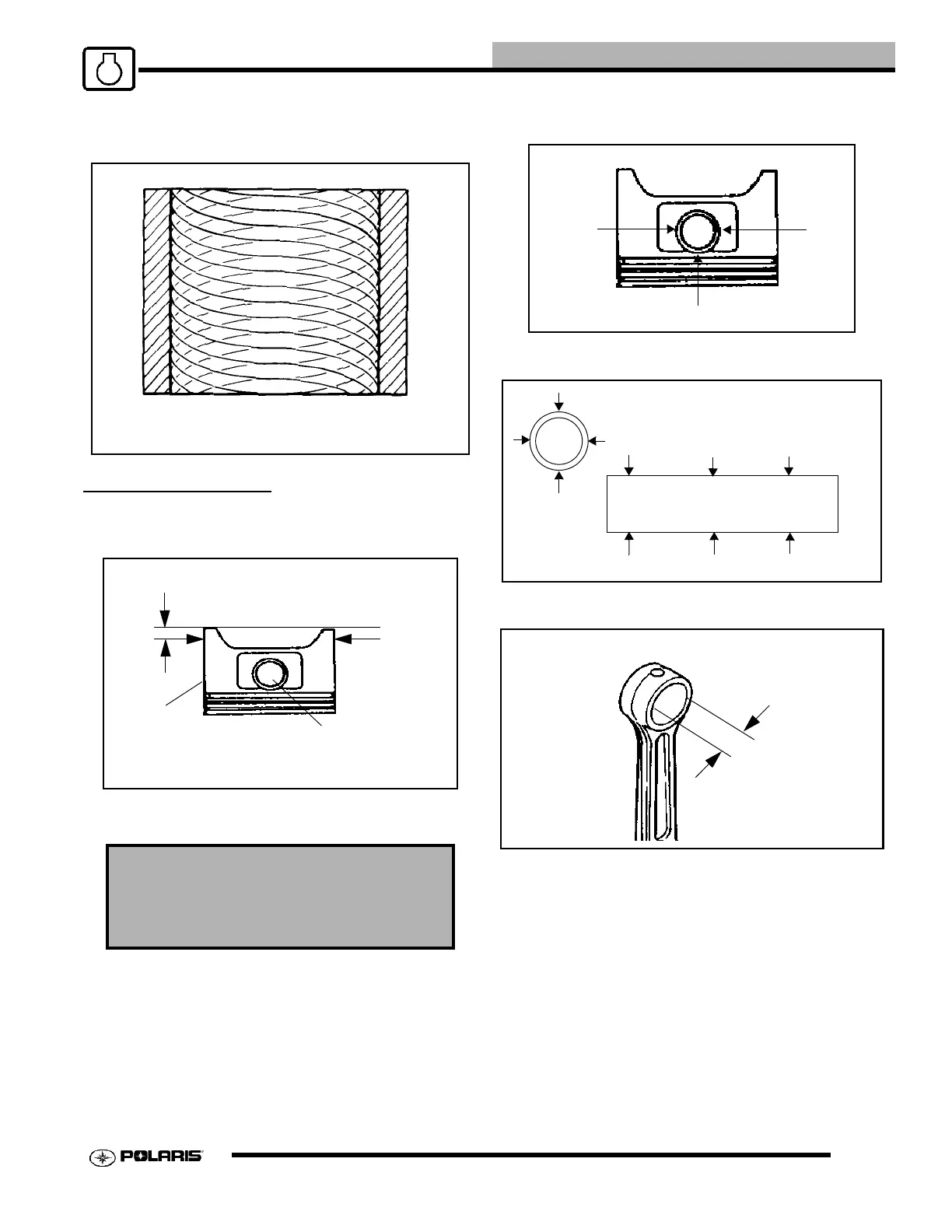

PISTON INSPECTION

1. Measure piston outside diameter at a point 7 mm up

from the bottom of the piston at a right angle to the

direction of the piston pin.

2. Subtract this measurement from the maximum

cylinder measurement obtained earlier.

3. Measure piston pin bore. Replace piston if out-of-

round

4. Measure piston pin O.D. Replace piston pin if out-of-

round.

5. Measure connecting rod small end ID. Replace

crankshaft if out-of-round.

Piston to Cylinder Clearance

Std: .0015- .0032” (0.038- 0.082 mm)

Limit: .0043” (.11 mm)

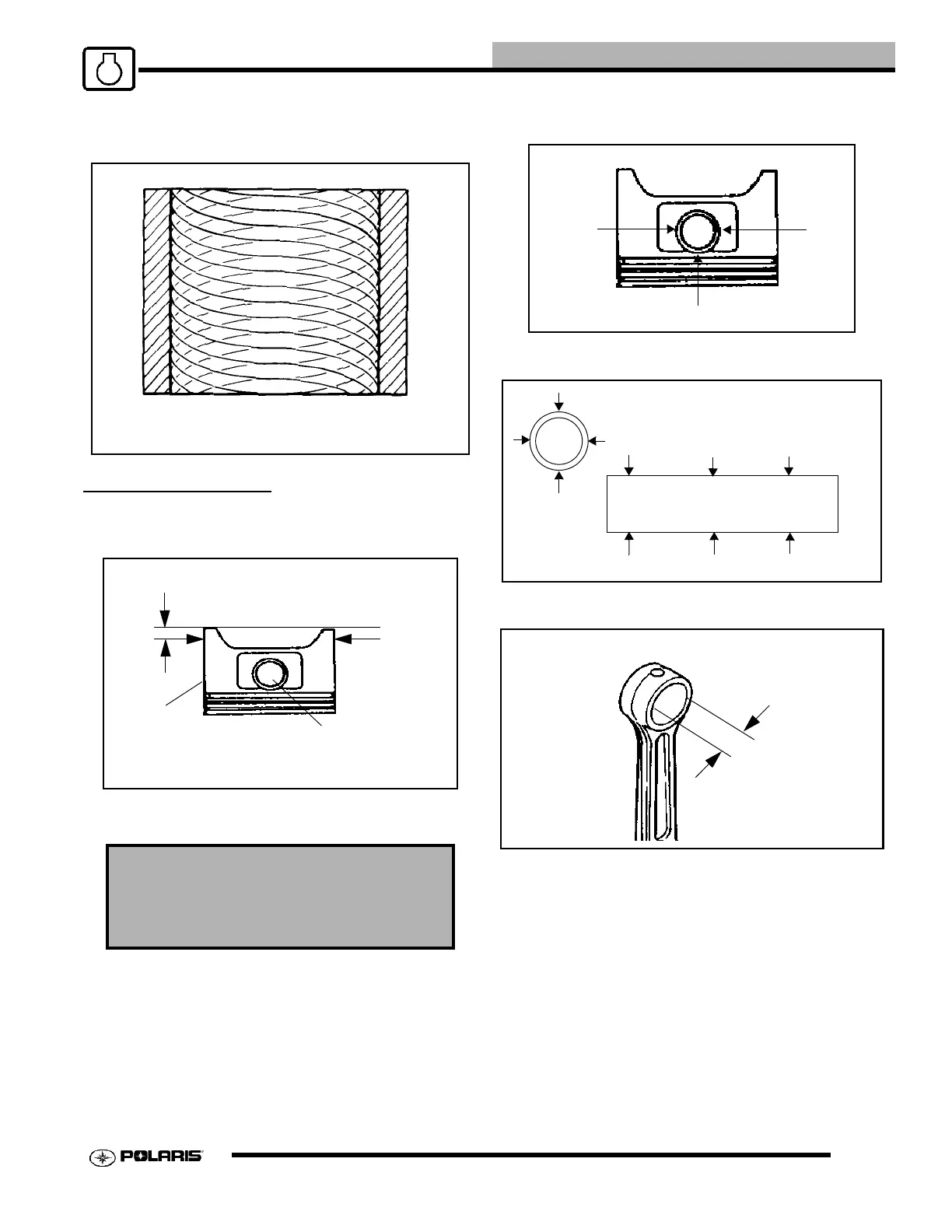

EXAMPLE OF CROSS HATCH PATTERN

Piston

Piston Pin

7mm

Piston Pin Bore

Piston Pin Measurement Locations

Loading...

Loading...