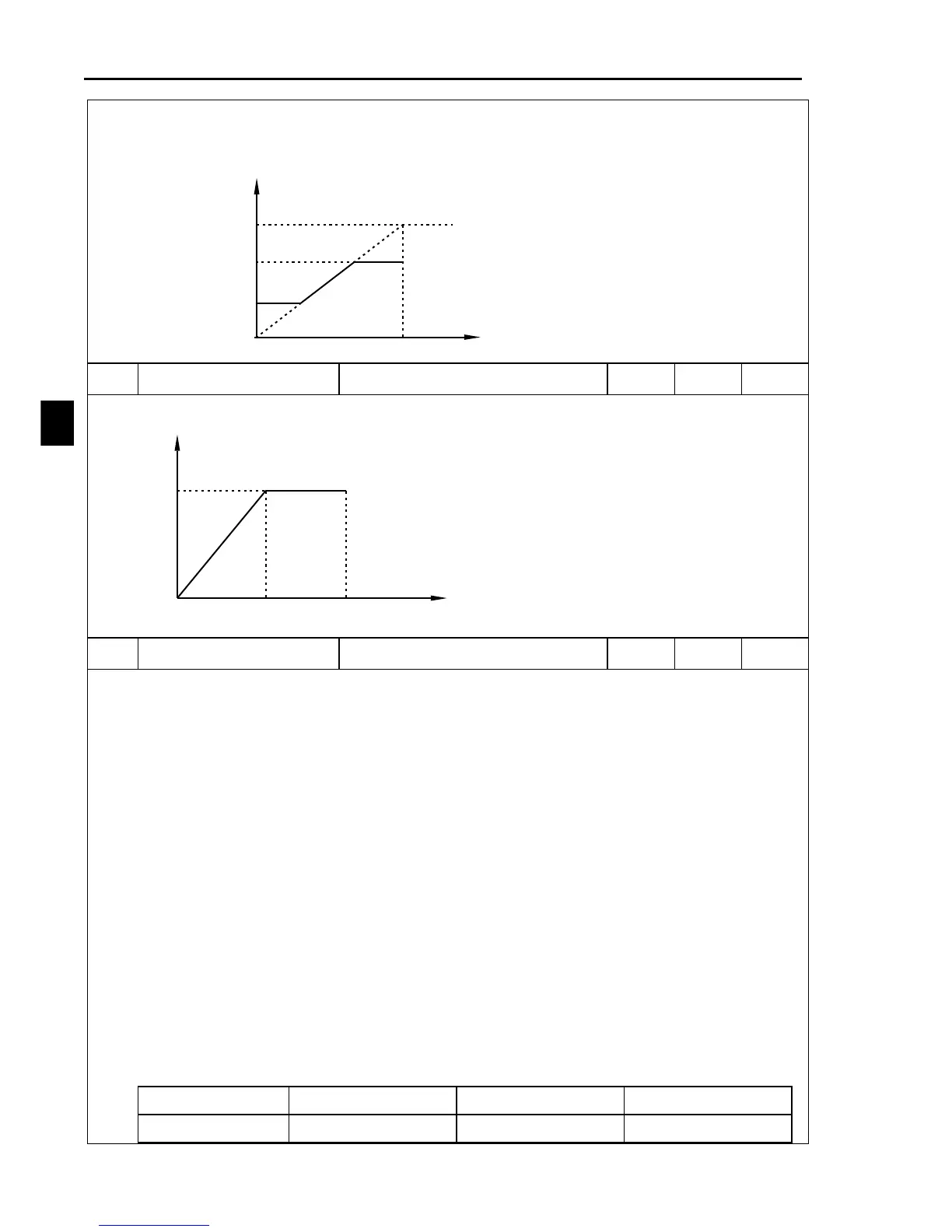

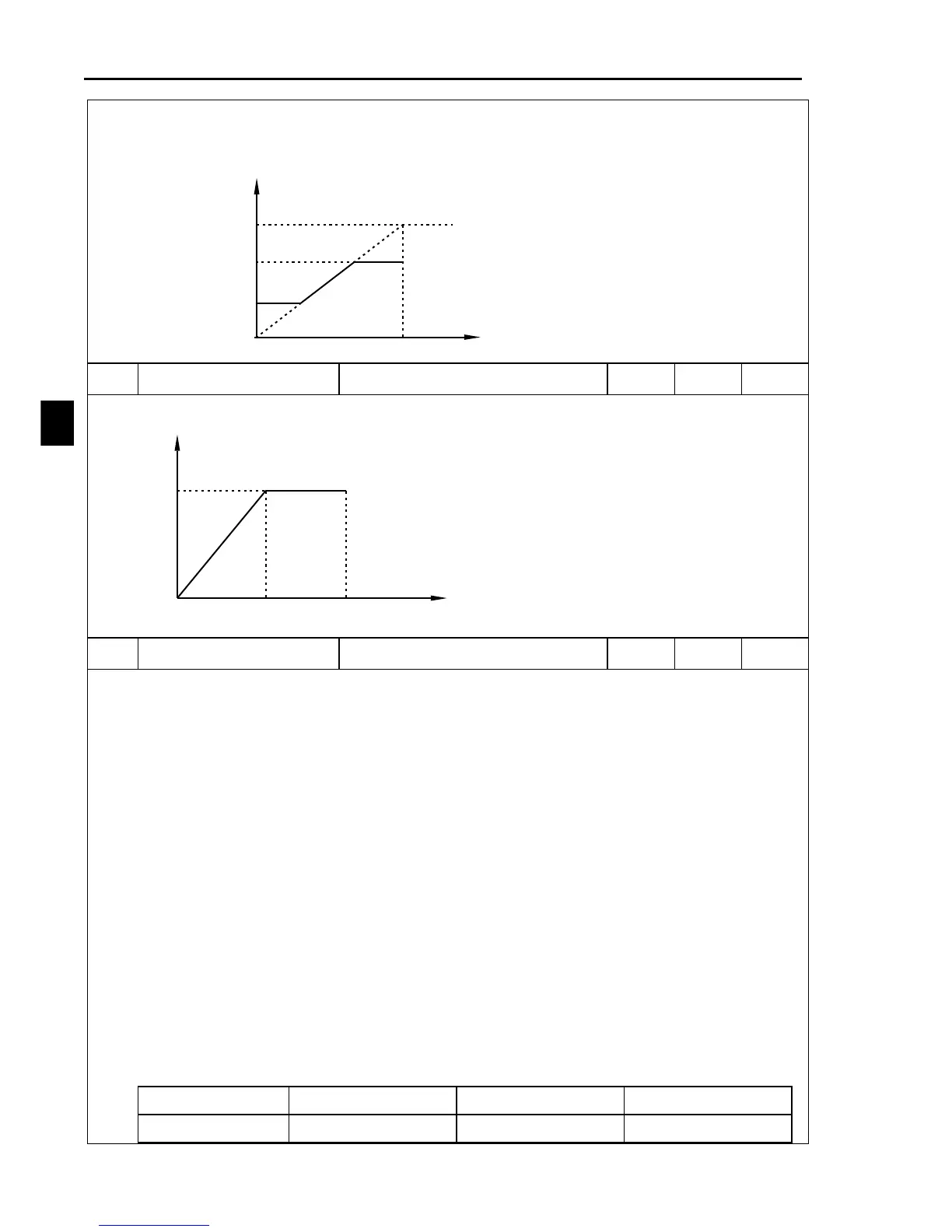

The operating frequency is lower frequency. Start the motor that in the status of stopping,

the inverter outputs accelerate starting from 0Hz, accordance with the step 1 acceleration time

towards the upper or the setting frequency to accelerate.when motor Stop,the operating frequency

decelerate according to deceleration time down to 0Hz.

This function is chiefly used to improve the possible noise and vibration during the

operation of frequency converter. When carrier frequency is higher, the output current has better

wave, the torque is great at lower frequency and the motor produces light noise. So it is very

suitable for use in the applications where great torque is output at low frequency quietly. But in

these applications, the damage to the switches of main components and the heat generated by the

inverter are great, the efficiency is decreased and the output capacity is reduced. At the same

time, more serious radio interference is resulted and special attention must be paid for application

where very low EMI is needed, and filter option can be used if necessary. Another problem for

application of high carrier frequency is the increase of capacitance-leakage current. The protector

for leakage current may invalidate function, and over current is also possibly caused.

When low carrier frequency is applied, the case is almost contrary to the above-mentioned

one.

Different motor has different reflection to the carrier frequency. The best carrier frequency is

gained after regulation according to actual conditions. The higher the motor capacity is, the lower

the carrier frequency should be selected.

The company reserves the right to limit maximum carrier frequency as following:

The relation between carrier frequency and Motor Noise, Electric disturbance, Switch

dissipation is expressed as following:

Loading...

Loading...