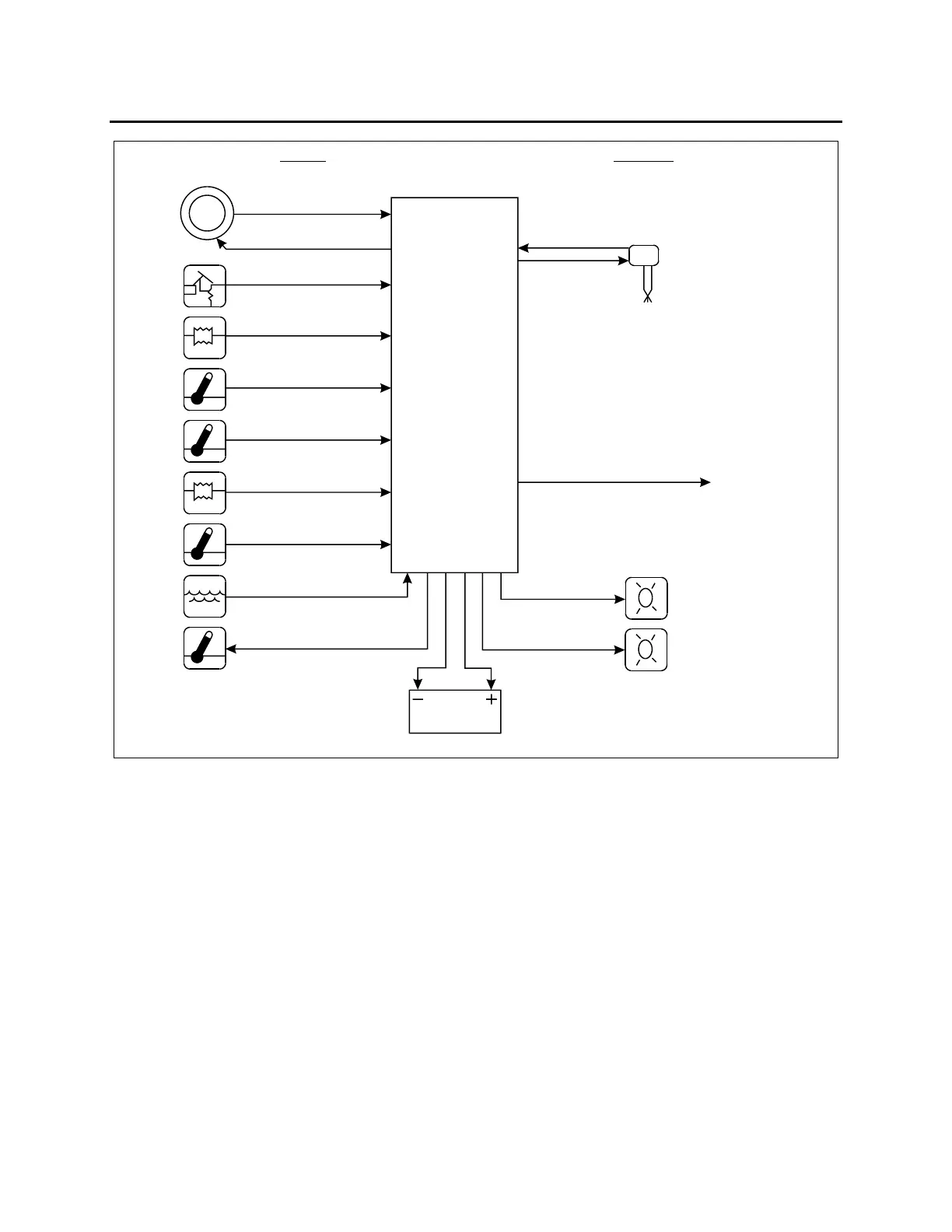

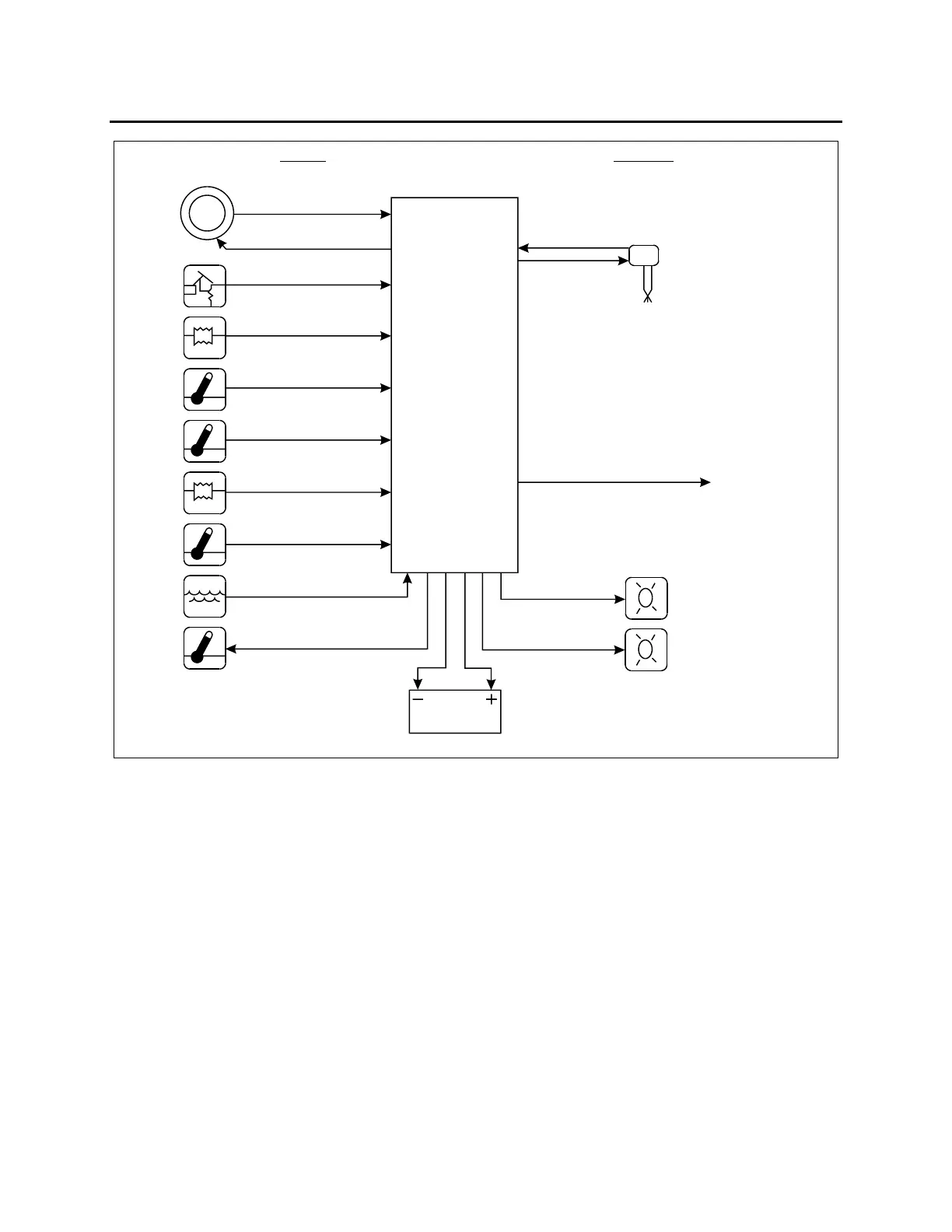

OTHER FEATURES

BATTERY

CHECK ENGINE

STOP ENGINE

DIAGNOSTIC DATA

LINK (DDL)

FEEDBACK

ELECTRONIC

CONTROL

MODULE

INJECTORS

OUTPUTS

INPUTS

TIMING

REFERENCE

SYNCH

REFERENCE

THROTTLE

POSITION

TURBO-BOOST

PRESSURE

AIR INLET

TEMPERATURE

OIL TEMPERATURE

OIL PRESSURE

COOLANT

TEMPERATURE

COOLANT LEVEL

FUEL TEMPERATURE

COMMAND

PULSE

SHEMATIC DIAGRAM OF DDEC IV SYSTEM 01092

DETROIT DIESEL ELECTRONIC

CONTROL (DDEC) SYSTEM

DDEC is an advanced-technology electronic fuel

injection and control system for Detroit Diesel

engines. As an integral part of the engine, the

DDEC system provides a number of

performance features and driver benefits

including improved fuel economy and

performance, reduced cold smoke and reduced

maintenance and repair costs. These

advantages are obtained by optimizing control of

the critical engine functions which affect fuel

economy, engine reliability and the performance

of the injectors.

Its major components include an Electronic

Control Module (ECM), Electronic Unit Injectors

(EUI), electronic throttle pedal and sensors. The

ECM, which provides central processing and

control of the DDEC system, contains the

following:

A microprocessor that continuously monitors

and analyzes the engine's performance

using sensors during engine operation;

Flash Random Access Memory (FRAM) that

stores ECM runtime software, which

contains engine control instructions;

Electrically Erasable Programmable Read-

Only Memory (EEPROM) that provides

instructions for basic engine control

functions such as rated speed and power,

engine governing, cold start logic and

diagnostics and an engine protection

system.

The Electronic Unit Injectors (EUI) operates on a

principle similar to the mechanical unit injector

system. However, a solenoid operated control

valve performs the injection timing and metering

53

Loading...

Loading...