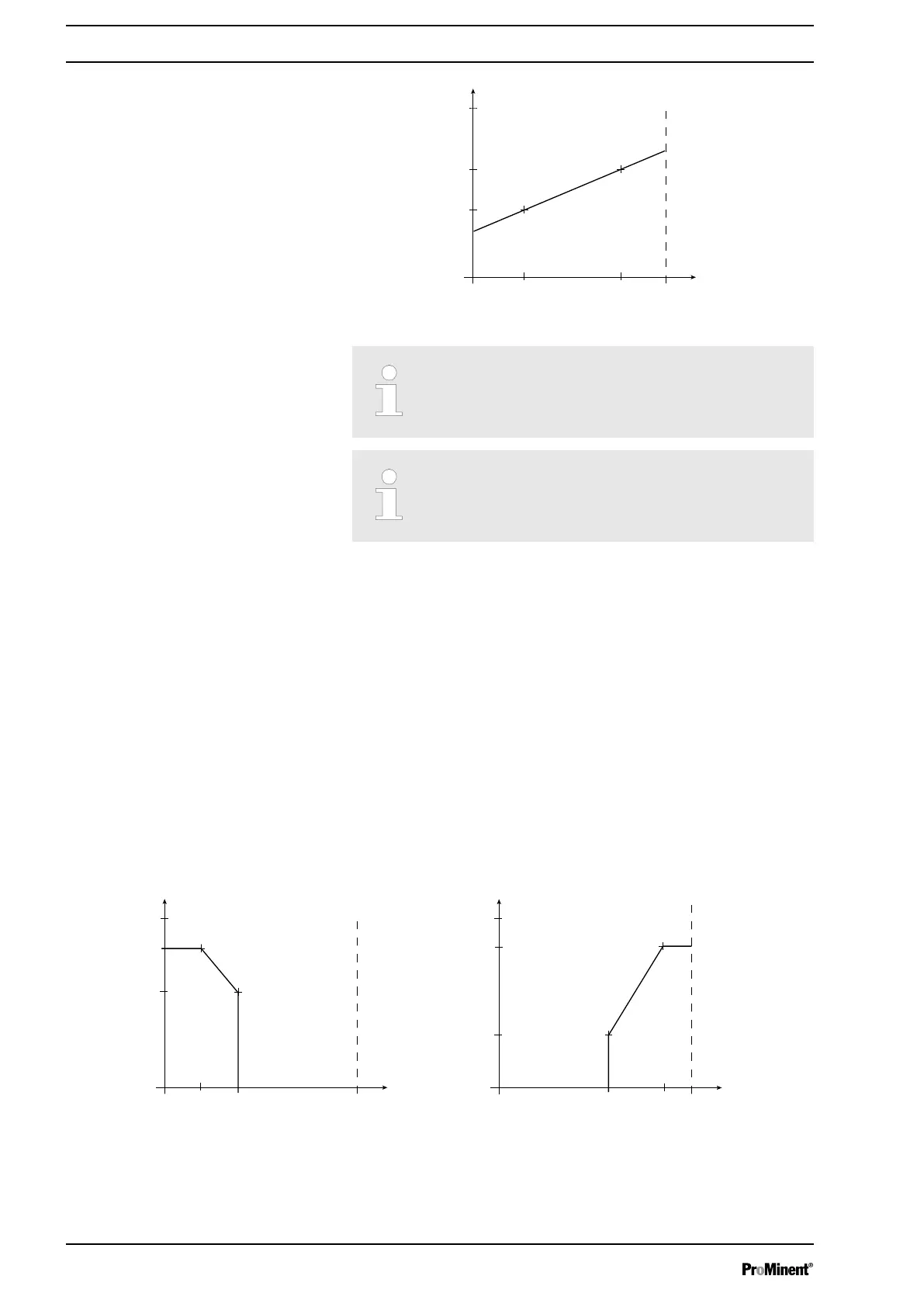

I [mA]

I 1

I 2

F1

F2

Fmax

0 20

P1

P2

B0088

Fig. 30: Speed-current diagram for "Linear curve"

Plot a diagram similar to the one above – with values for

(I1, F1) and (I2, F2) – so that you can set the pump as

desired!

The smallest processable difference between I1 and I2

is 4 mA (ll I1-I2 ll ≥4 mA).

In the

‘Error message’

menu item, you can activate error processing for

these types of processing.

‘Lower side band’

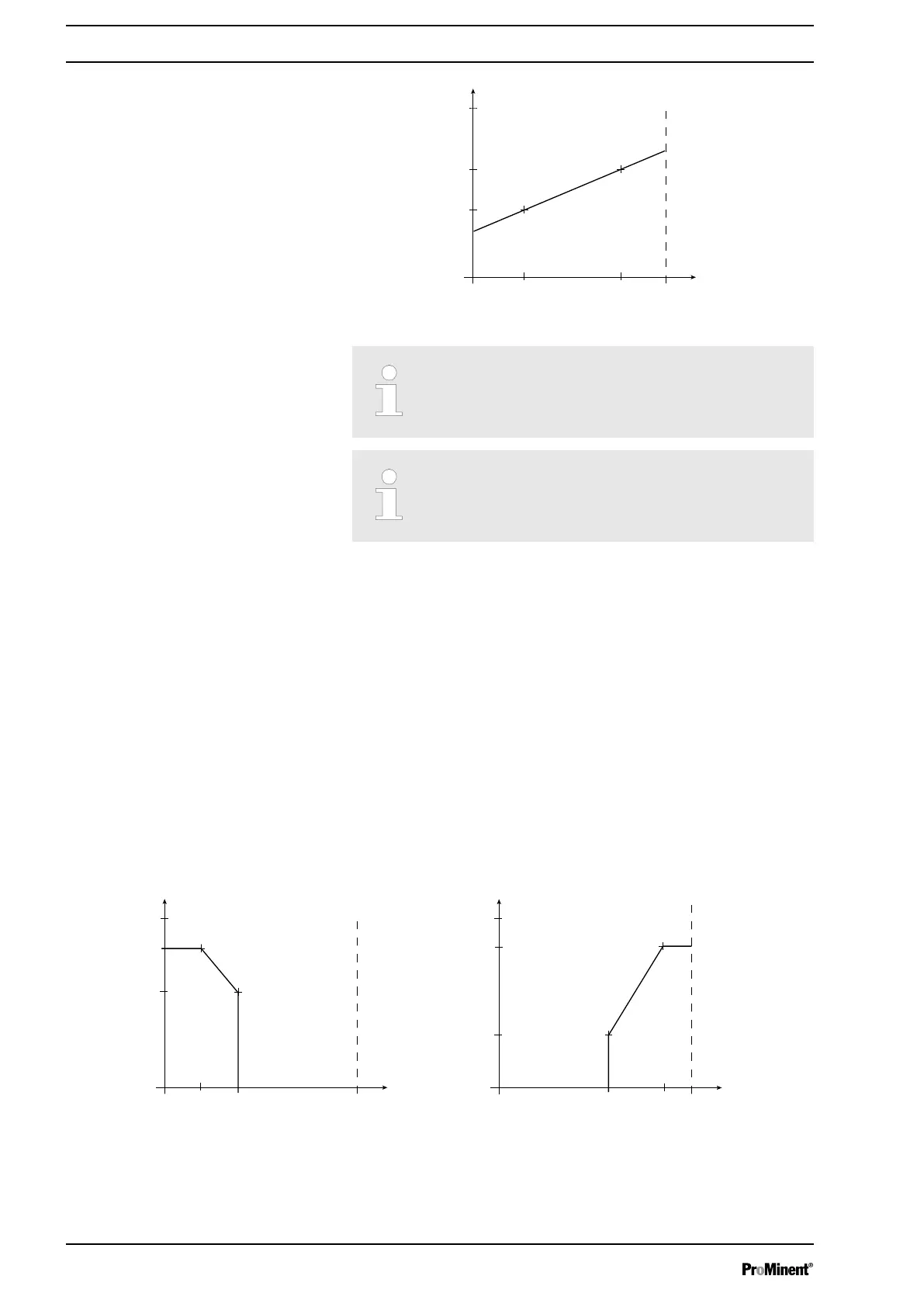

Using this type of processing, you can control a metering pump using the

current signal as shown in the diagram below.

However, you can also control two metering pumps for different feed

chemicals via a current signal (e.g. one acid pump and one alkali pump

using the signal of a pH sensor). To do this, connect the pumps electrically

in series.

In the

‘Error message’

menu item, you can activate error processing for

these types of processing.

I [mA]

I 1 I 2

F2

F1

0 20

a) b)

P1

P2

Fmax

B0089

I [mA]

I 1

I 2

F1

0 20

P1

P2

F2

Fmax

Fig. 31: Speed-current diagram for a) Lower side band, b) Upper side band

‘Upper side band’

Error processing

Error processing

Set up /

‘Menu’

48

Loading...

Loading...