CHAPTER 8

72 RCM - Sprayer and AIM Command FLEX™ II Calibration and Operation Manual

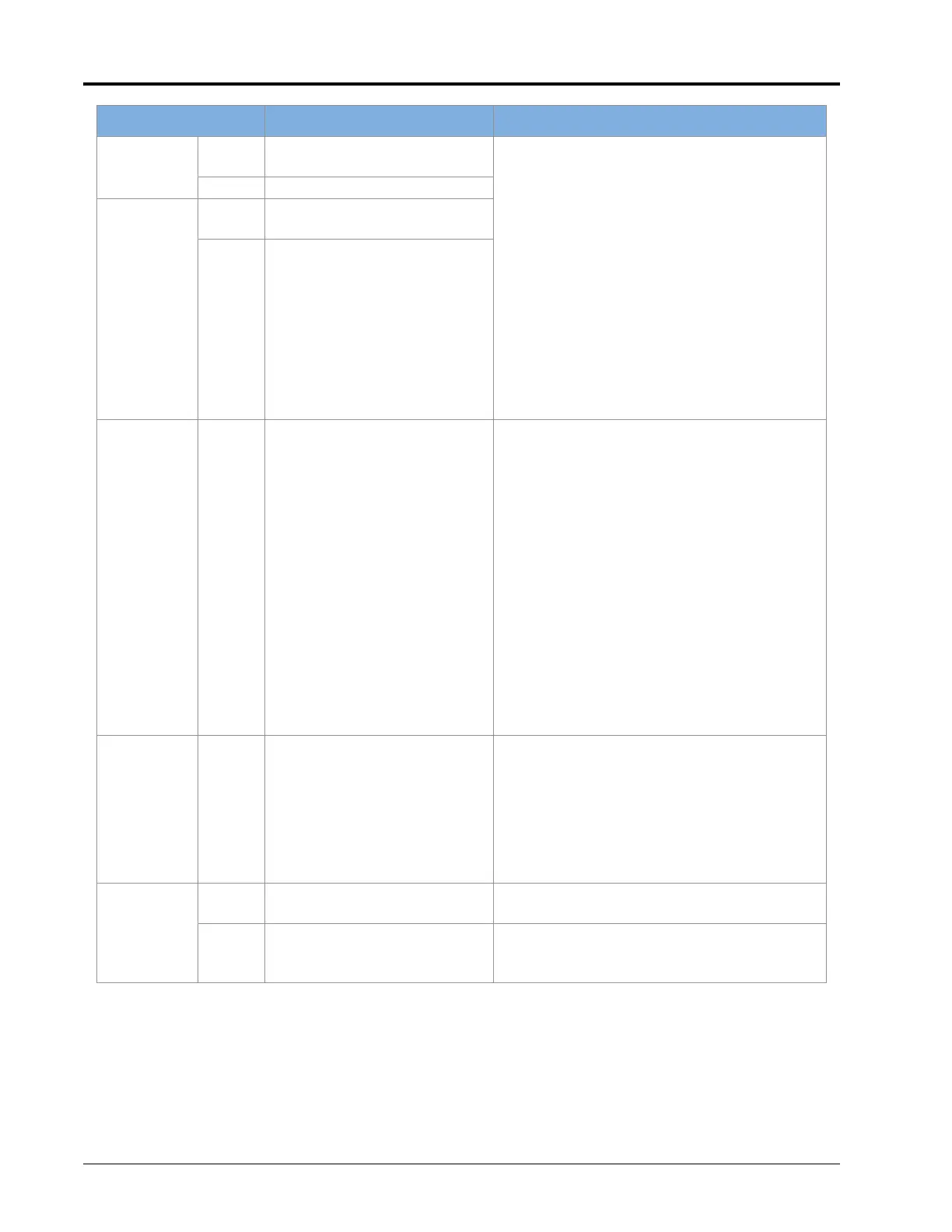

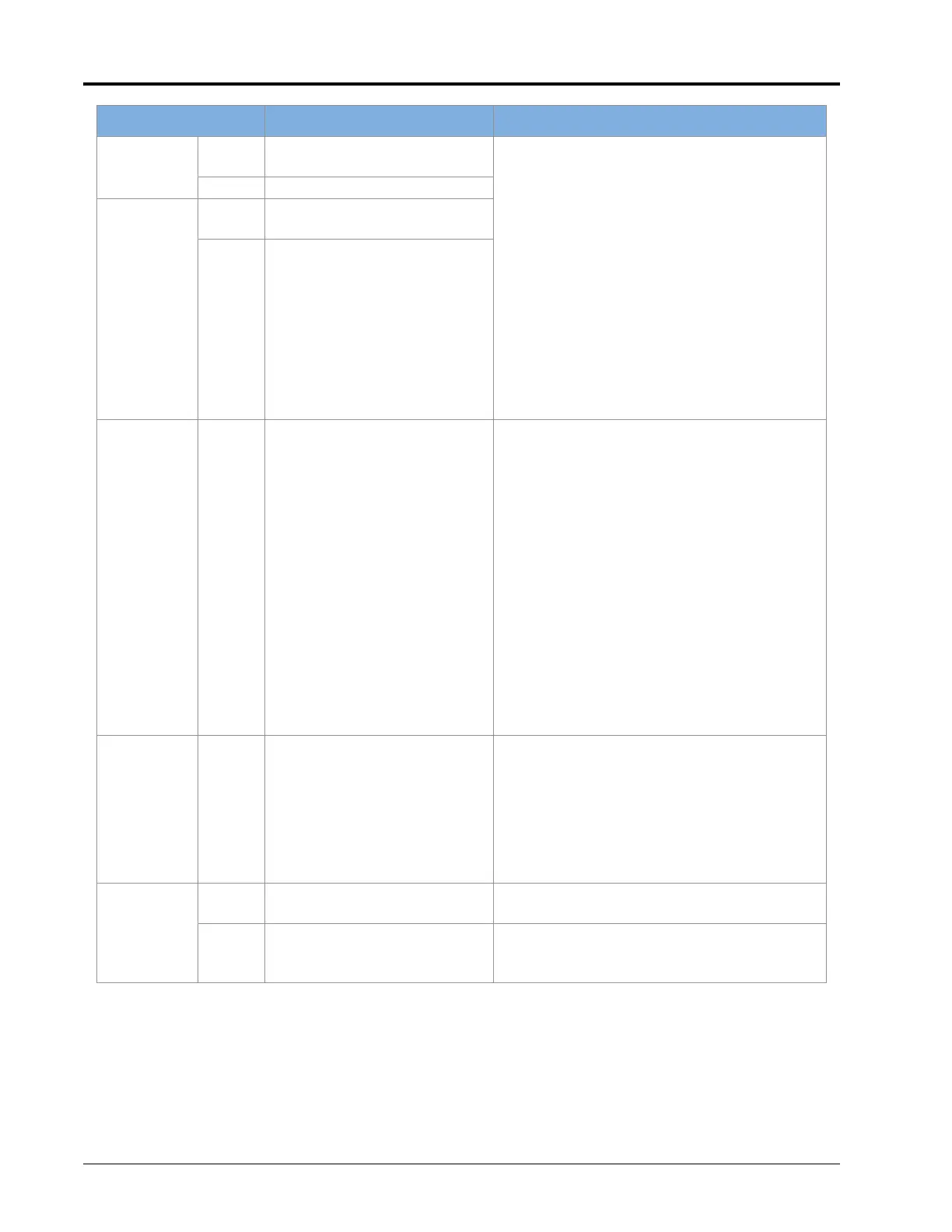

523140

.13

NCV poppet health limit -

single

• Check NCV for debris, damaged or worn

poppet or spring, corrosion, and any sort of

contamination. Clean or rebuild NCV as

necessary.

• Check system strainer size. Ensure a 80 mesh

or finer is being used.

• Check plumbing system and strainers for

debris, particle deposits, metal filings or any

material that may cause plugging. Clean out

system plumbing or strainer.

• Check that correct tip size is selected and

installed. Consider increasing tip size.

• Check for error to extinguish at different NCV

duty cycles or product flow rates

.31 Stuck poppet - single

523141

.13

NCV poppet health limit -

multiple

.31 Stuck poppet - multiple

523142 .31

Unexpected system flow

decrease

• Check sprayer plumbing for any major

blockage in system or a major leak ahead of

flowmeter.

• Check that any sump, master valves, electric

boom valves, hand valves, throttling valves,

check valves, and drain valves are open, not

obstructed, or in correct positions.

• Check for pinched hoses.

• Check strainers for obstructions. Clean if

necessary.

• Check that correct tip size is selected and

installed.

• Check for empty product tank.

• Check for correct flowmeter calibration value.

• Check system pump for proper operation.

523143 .31

Unexpected system flow

increase

• Check sprayer plumbing for a major leak

downstream of flowmeter.

• Check that correct tip size is selected and

installed on all tips and fence row nozzles.

• Check that electric or manual valves are in

correct positions.

• Check for correct flowmeter calibration value.

523192

.13

Sparge pressure sensor not

calibrated

• Select correct sparge pressure sensor

calibration value.

.4

Sparge pressure sensor not

detected

• Check the sparge transducer connection and

cabling for damage. If necessary, replace the

cable or pressure sensor.

Code ID Description Recommended Actions

Loading...

Loading...