Chapter 3

16 Sidekick Pro Installation & Operation Manual

3-Way Valve

A 3-way valve must be plumbed after the closed calibration system to allow chemical to be directed either back

to the chemical tank or to the point of injection.

Hoses

Use chemically resistant hose compatible with the chemicals which will be used with the injection system.

Follow the same hose specifications as described in the Pump Outlet section on page 15 with the closed

calibration system.

Recirculation Check Valve

A recirculation and priming check valve (P/N 333-0011-100) must be plumbed into the recirculation line

between the 3-way valve on the outlet side of the injection pump and the chemical tank. This check valve is

required to allow air to bleed off during priming of the injection pump. The recirculation and priming check valve

is also necessary to allow the system to detect if the pump is primed. See Figure 1 on page 9.

Plumb the Recommended Pump Rinse System

An injection pump rinse system is recommended to enhance the performance of the Sidekick Pro injection

pump and provide a clean method for changing between chemicals. The rinse system flushes chemical build

up or residues which may collect in the injection pump.

Note: Some components of the recommended rinse system may not be available from Raven. The

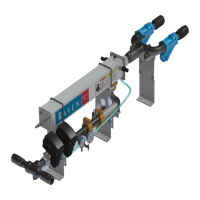

following components may be purchased separately and plumbed as shown in Figure 8 on

page 17.

• Clean water supply tank

• Strainer (80 Mesh)

• 1/2 PSI check valve (P/N 333-0011-087)

• Appropriate hose or tubing

• Miscellaneous fittings

Loading...

Loading...