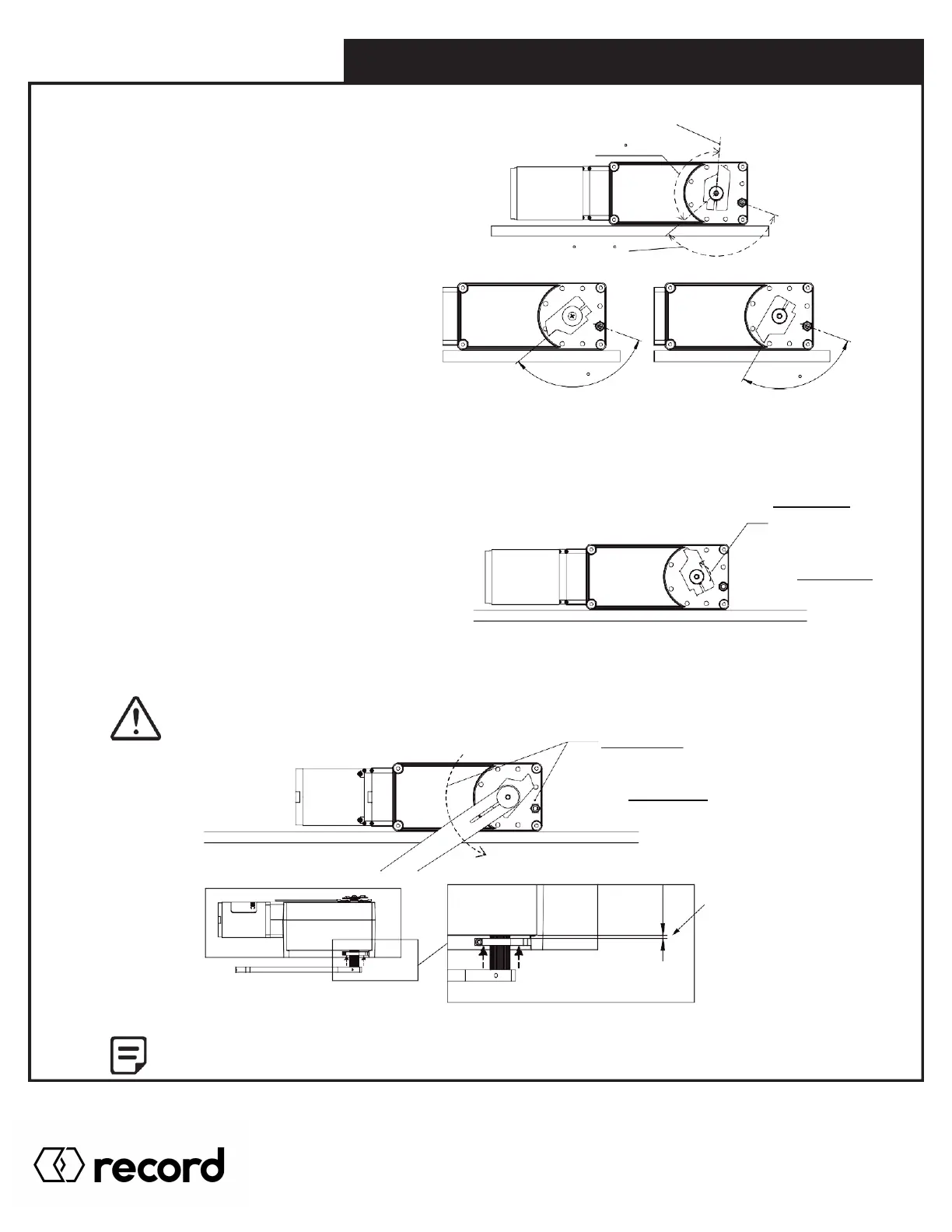

STEP 3 - Adjust Stopper Position

To add more closing force to the door, you must

re-insert the spline stop onto the shaft. The

recommended maximum position is about a

third of a turn (~135 degrees) as shown below.

Anything beyond this point puts excessive stress

on the spring, and also exceed AAADM

recommendation of closing force.

ADDING SPRING TENSION,

MAX POSITION

135 MAX

120 OR 90

DEPENDING ON SPRING

STEP 4 - Eliminate Spring Slack

“W5-105” REGULAR SPRING

FACTORY DEFAULT POSITION

“W5-106” XP SPRING

FACTORY DEFAULT POSITION

Once the spline stop is in the appropriate position, eliminate the existing spring slack by hand manually turning the spline

stop towards the nut.

For Right Hand operator, turn the spline stop counter clockwise towards the nut.

For Left Hand operator, turn the spline stop clockwise towards the nut.

This step is to ensure the spring is tight from the get go,

and does not lose any tension (closing force) after wind.

RH OPERATOR

TURN SPLINE STOP

COUNTER CLOCKWISE

MANUALLY TO ELIMINATE

SLACK IN SPRING.

FOR LH OPERATOR,

TURN CLOCK WISE.

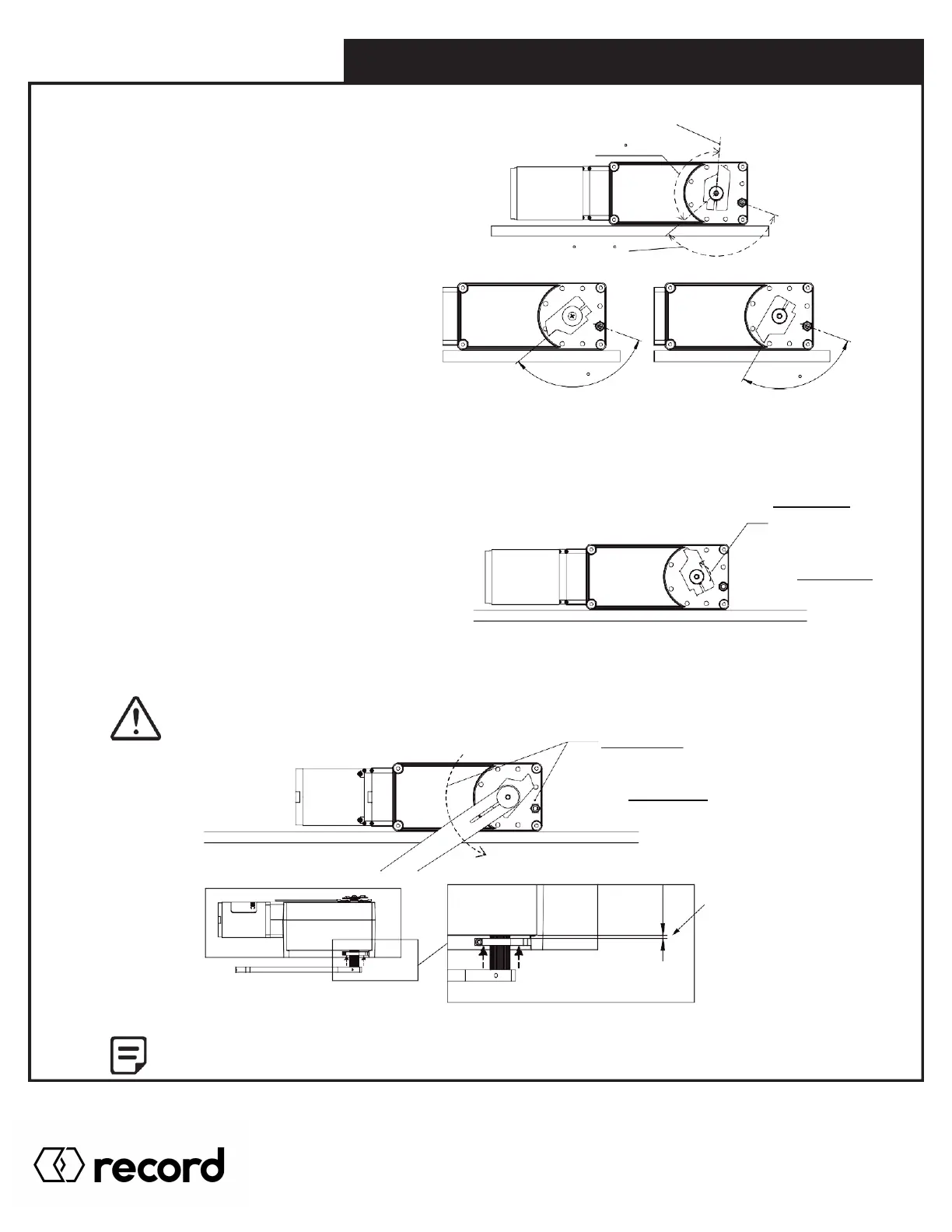

STEP 5 - Add Spring Tension

Using the operator arm, wind the stop until it is above the nut.

Remember to secure operator as injury may occur while adjusting spring tension,

if operator not held in place.

RH OPERATOR

USING OPERATOR ARM,

WIND COUNTER CLOCK WISE

UNTIL STOPPER IS ABOVE NUT.

FOR LH OPERATOR,

WIND CLOCK WISE.

0.125in

3.18mm

After adjustment, reinstall operator and other components as shown in section 2.0 and onward.

Pg. 42

HA8-SP Manual V. 7.0

Record Canada Inc.

Toll Free: 1-877-348-6837

info.ditec.ca@recorddoors.com

www.recorddoors.ca

Record USA Inc.

Toll Free: 1-866-901-4284

info.ditec.us@recorddoors.com

www.recorddoors.com

Loading...

Loading...